Fuel pressure sensor error within identification range

A pressure sensor and pressure technology, applied in the direction of measuring fluid pressure, instruments, power devices, etc., can solve problems such as unavailability and negative impact on driver satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

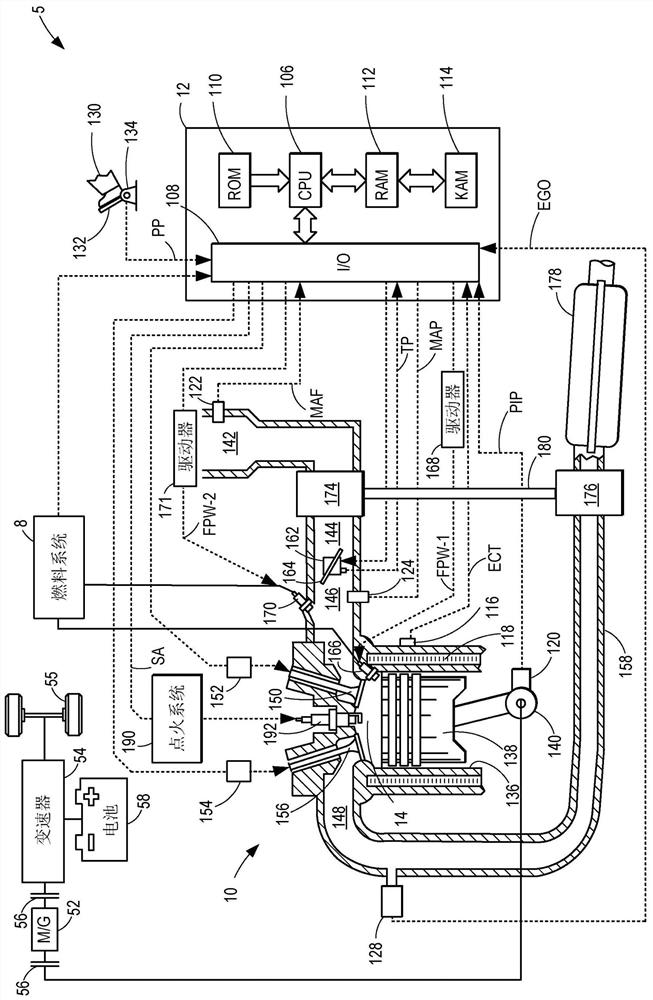

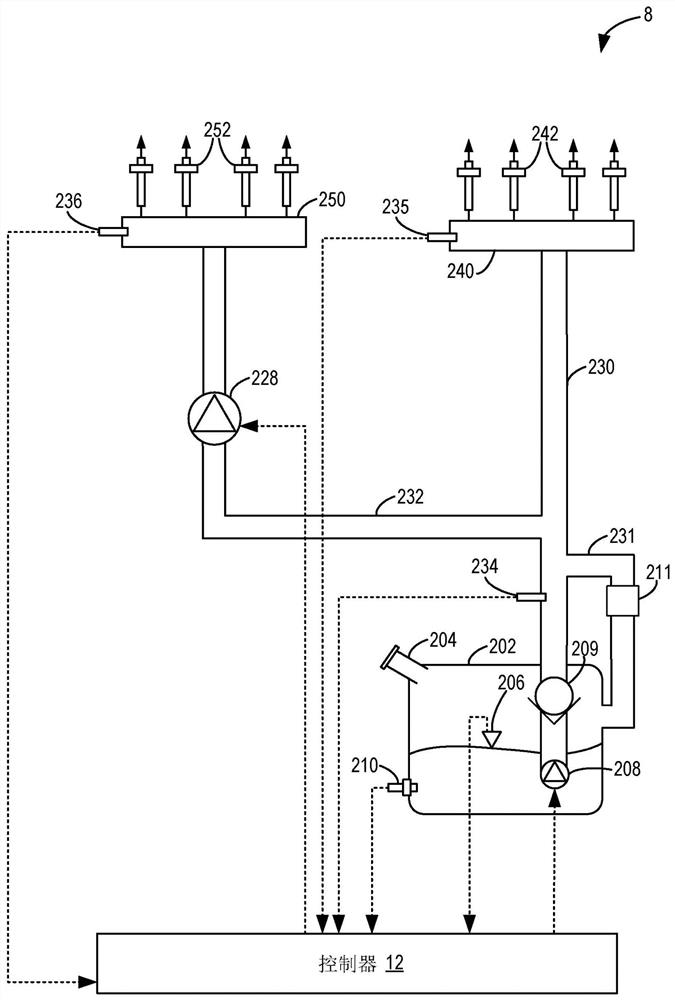

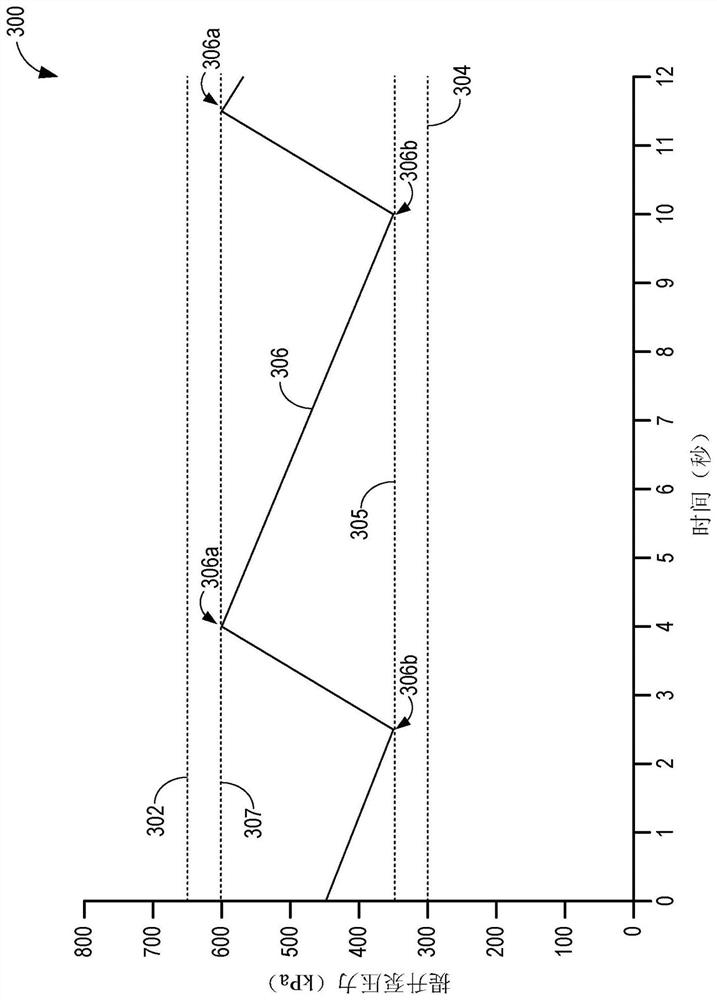

[0026] The following description refers to the control engine (such as figure 1 A fuel lift pump in a fuel system of an engine shown in ) and a system and method for diagnosing an error within the range of a pressure sensor disposed downstream of the fuel lift pump and adjusting operation of the fuel system in response to the diagnosis. like figure 2 As shown in , the fuel system may include both port and direct fuel injectors and associated fuel rails. However, the methods and systems described herein are equally applicable to fuel systems that include port injectors and do not include direct injectors, and fuel systems that include direct injectors and do not include port injectors, as well as other types of A fuel system for fuel injectors that receive pressurized fuel from a fuel lift pump. Pulse mode with closed loop feedback control (e.g. according to Figure 5A to Figure 5C The routine shown in ) operates the lift pump, where a voltage pulse is supplied to the lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com