Method for regulating warpage of polarizer

A polarizer and warping technology, which is applied in the direction of optics, optical components, polarizing components, etc., can solve problems such as warping, and achieve the effects of alleviating relative sliding and wide speed control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention will be further described.

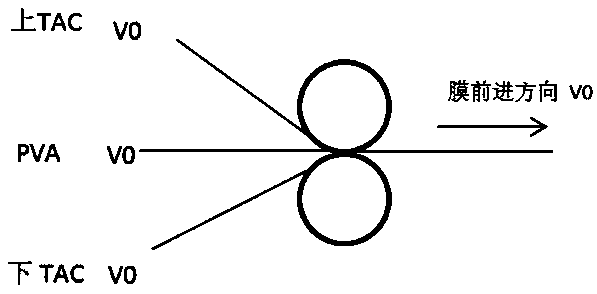

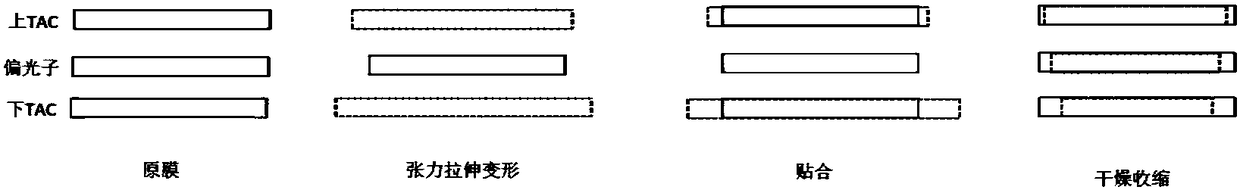

[0026] according to Figure 1-2 , the bonding method of the common mode: the bonding speed V0 of the upper / lower TAC and PVA is the same, so the film feeding amount of the upper / lower TAC and PVA in the bonding process is the same, due to the tensile deformation of the upper / lower TAC The difference between the drying shrinkage rate and the drying shrinkage rate leads to warping due to the difference in the deformation of the upper and lower TACs after the polarizer body is heated and dried.

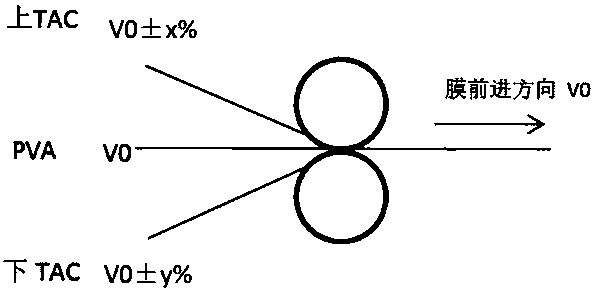

[0027] according to Figure 3-4 , the bonding method of the new mode: based on the feed speed V0 of the PVA film, the feed speed of the upper / lower TAC can be fine-tuned to control the feed amount of the upper / lower TAC; in addition, according to the characteristics of each material Adjust the value of the speed difference to correspond to different TAC properties, and adjust the warping to an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com