A simulation test device for loss of aeroengine rotor blades

An aero-engine and simulation test technology, applied in jet engine test, gas turbine engine test, etc., can solve the problems of insufficient fly-away speed control accuracy, inability to simulate the vibration response of the whole machine, and no inclusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

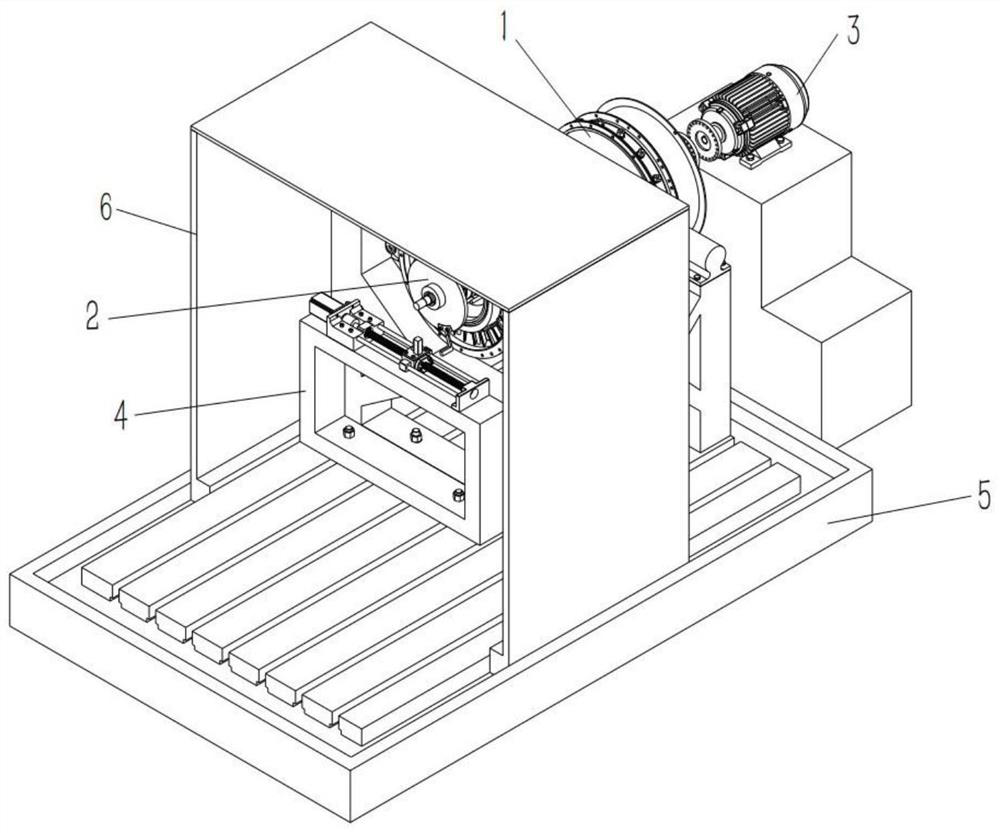

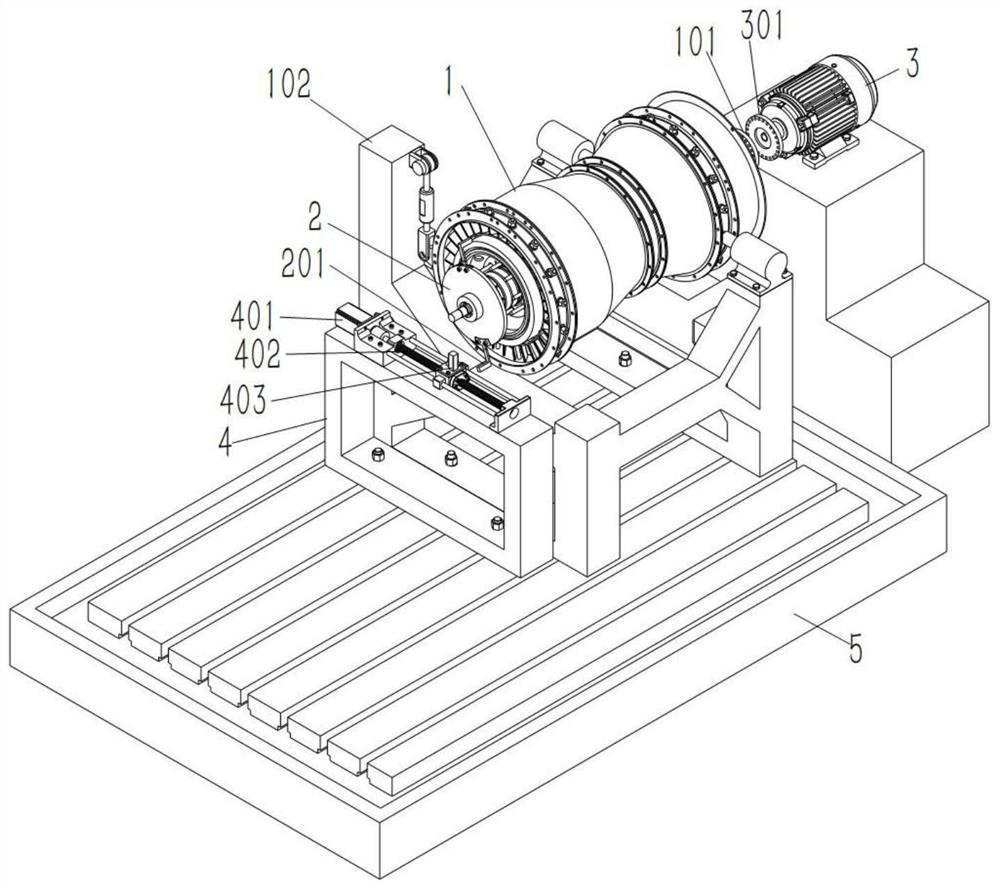

[0032] In order to clearly illustrate the technical characteristics of this patent, the following describes this patent in detail through specific implementation methods and in conjunction with the accompanying drawings. The structure of the aero-engine rotor tester and the installation stand recorded in this case is similar to the structure recorded in the article "Analysis of the Influence of Mounting Joint Stiffness on the Coupled Vibration of the Engine Whole Machine" in the Journal of Aerodynamics, Volume 32, Issue 7, July 2017 .

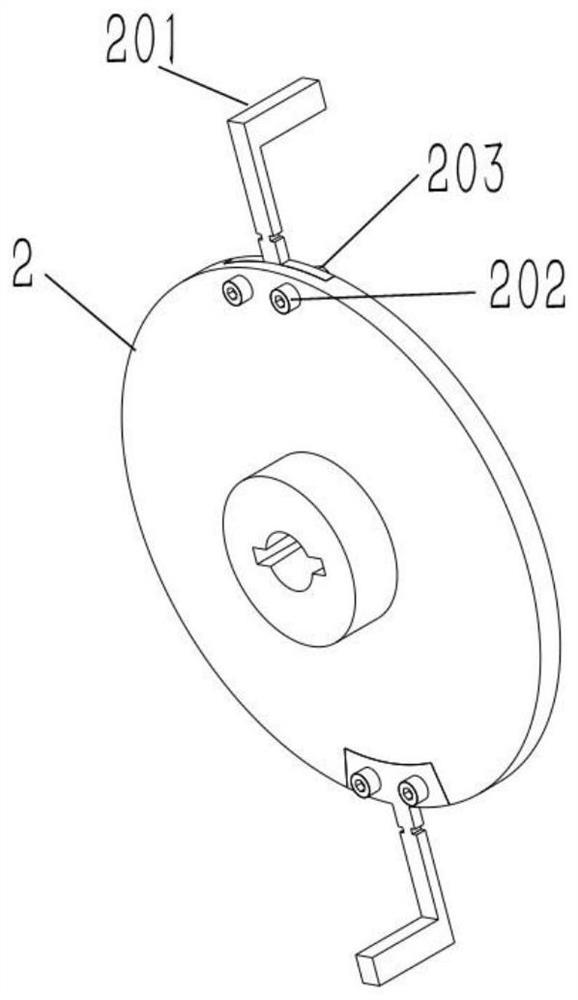

[0033] The present invention as Figure 1-4 As shown, it includes an installation stand 102 for installing the aero-engine rotor tester 1, a rotary drive assembly for driving and installing the aero-engine rotor tester 1, an L-shaped blade 201 for simulating blades, and an L-shaped blade for impacting. Impact system 4 of 201;

[0034] The L-shaped blade 201 is fixedly connected to the output shaft of the aero-engine rotor tester 1, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com