Kinematic calibration

A technology of kinematics and kinematics models, applied in the field of kinematics calibration, which can solve problems such as inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

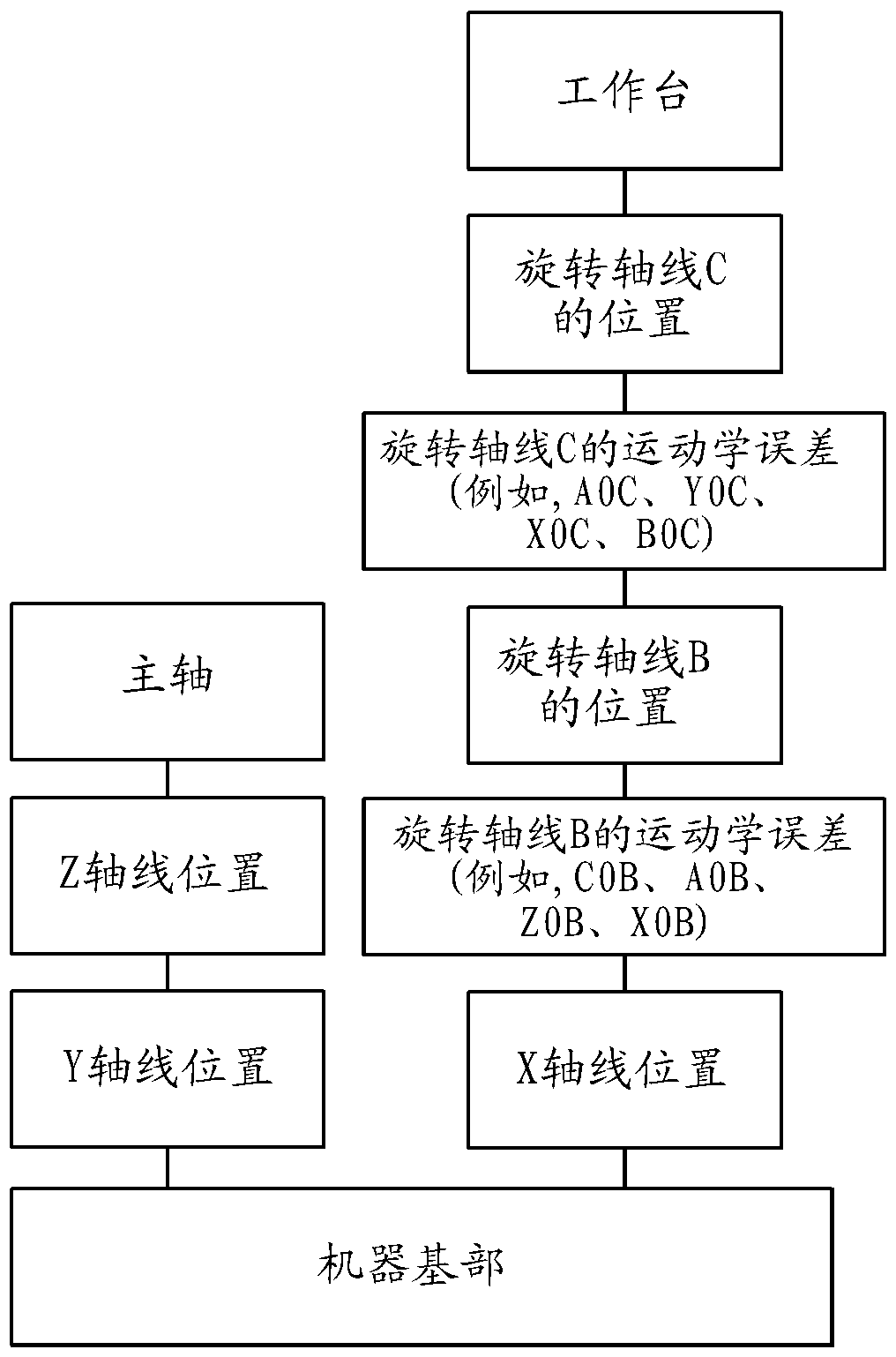

[0029] figure 1 A typical multi-spindle machine tool 1 with three linear axes X, Y and Z and two rotational axes B and C is shown. The table 2 can move linearly along the axis X. The linear movement along the Y and Z axes takes place via the handpiece 3 on the other hand. The table 2 is rotatable about the axes C and B of rotation. Another axis of rotation A can be implemented in the machine tool 1 , for example by foreseeing the possibility of tilting the handpiece 3 about the X-axis (see arrow A).

[0030] figure 2 show figure 1 The table 2 already shown in FIG. 2 has a fixture 5 mounted on it and has a calibration ball 6 on top of it. The position of the calibration ball 6 (respectively, its center) is measured by a touch probe 7 mounted on the machine head 3 of the machine tool 1 .

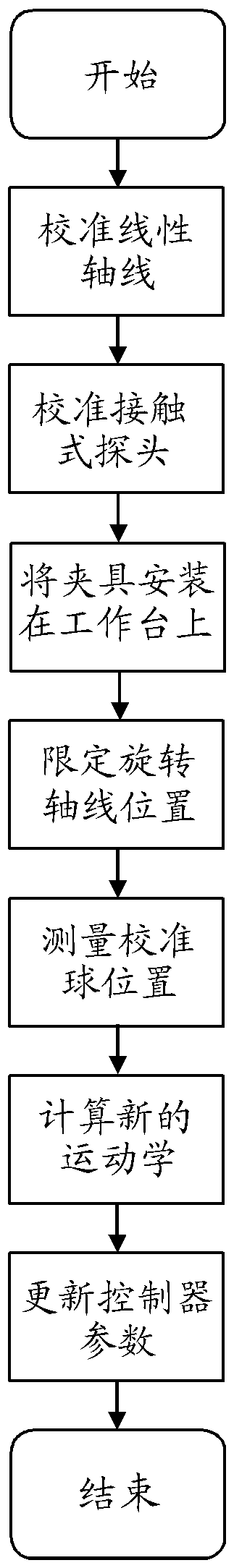

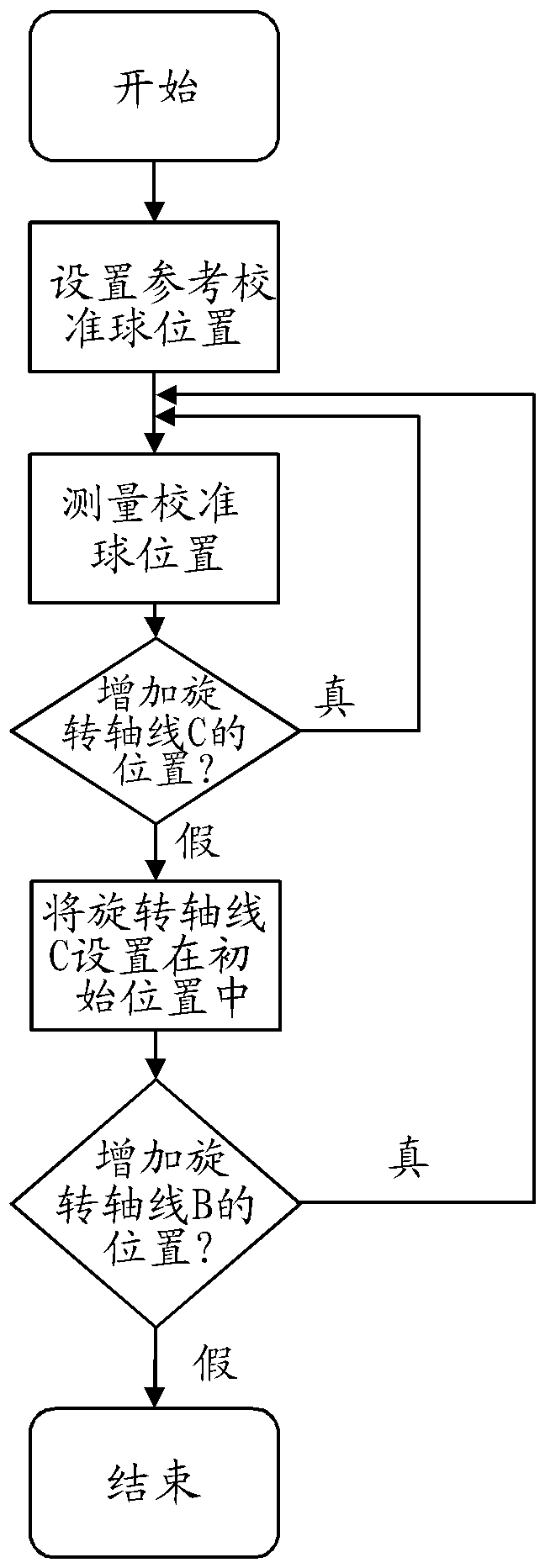

[0031] Hereinafter, the calibration method of the present invention will be described based on examples. image 3 Shows the entire proposed calibration process. Before starting the ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com