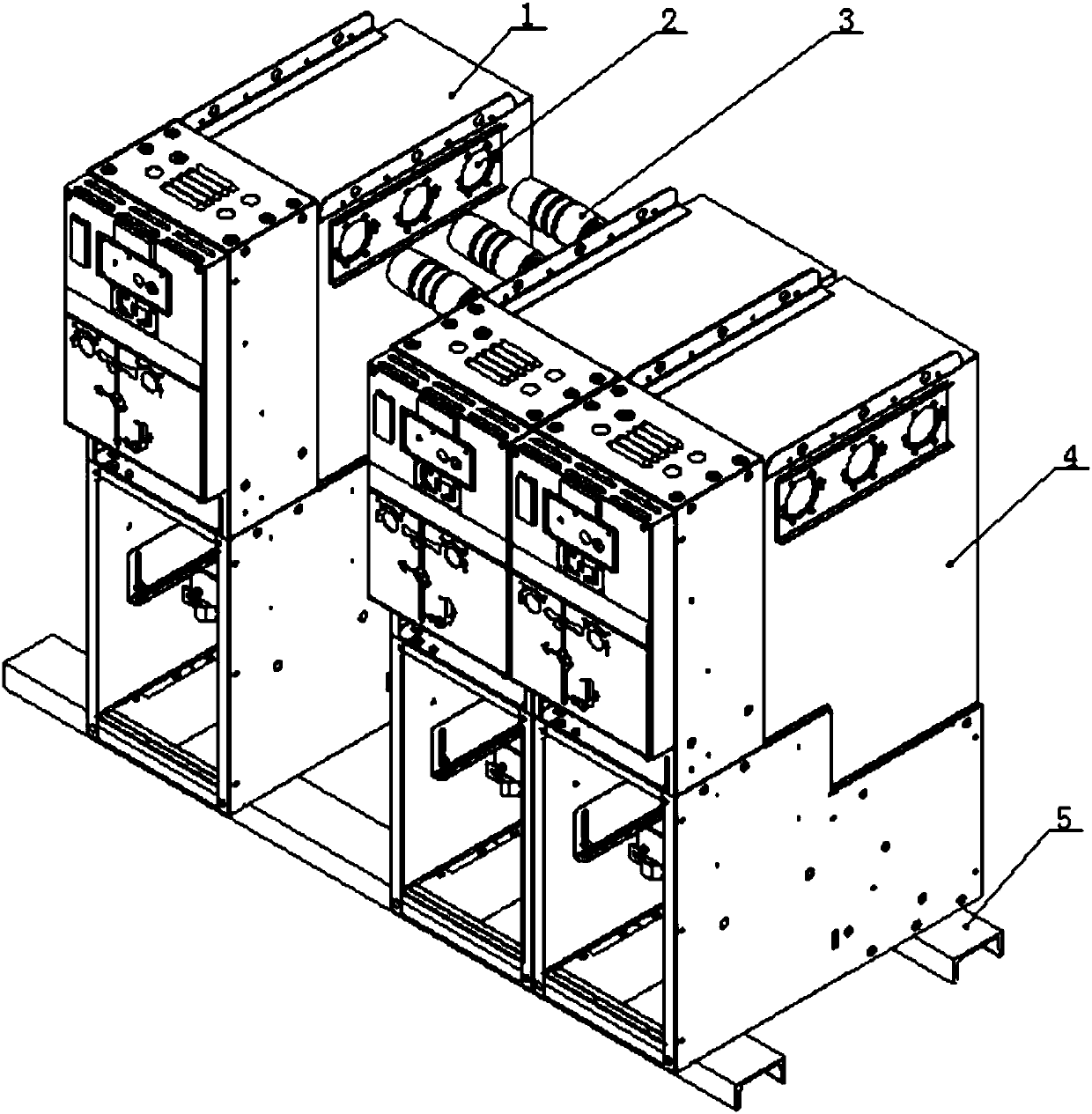

Novel ring network cabinet assembling device and assembling method

A ring network cabinet, a new type of technology, applied in the direction of switchgear, substation/switch layout details, electrical components, etc., to achieve the effect of light weight, simple operation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The novel ring network cabinet uniting device of the present invention includes a cabinet body tensioner and a cabinet body guider. The cabinet body tensioner includes the active part of the cabinet body tensioner and the auxiliary part of the cabinet body tensioner.

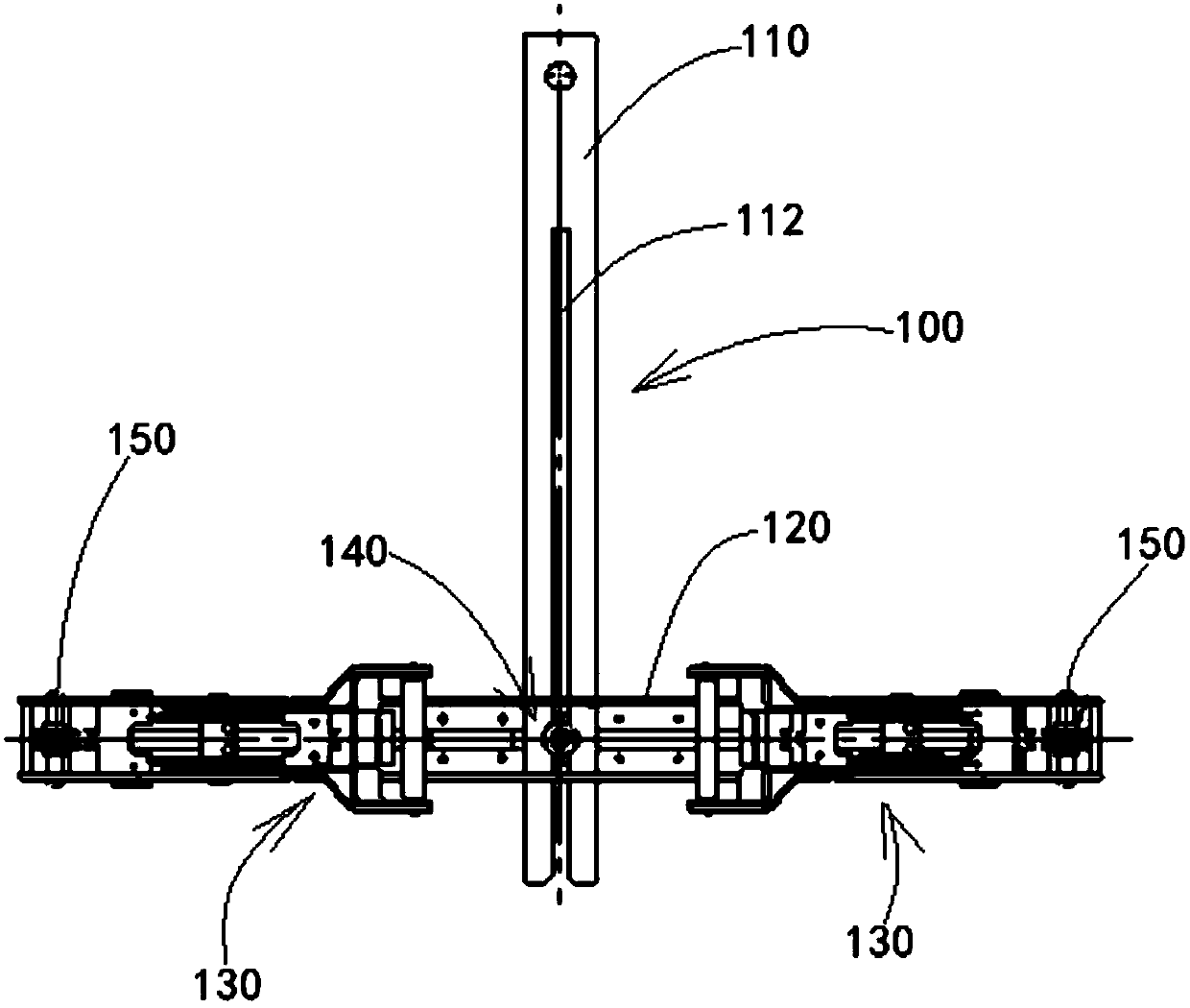

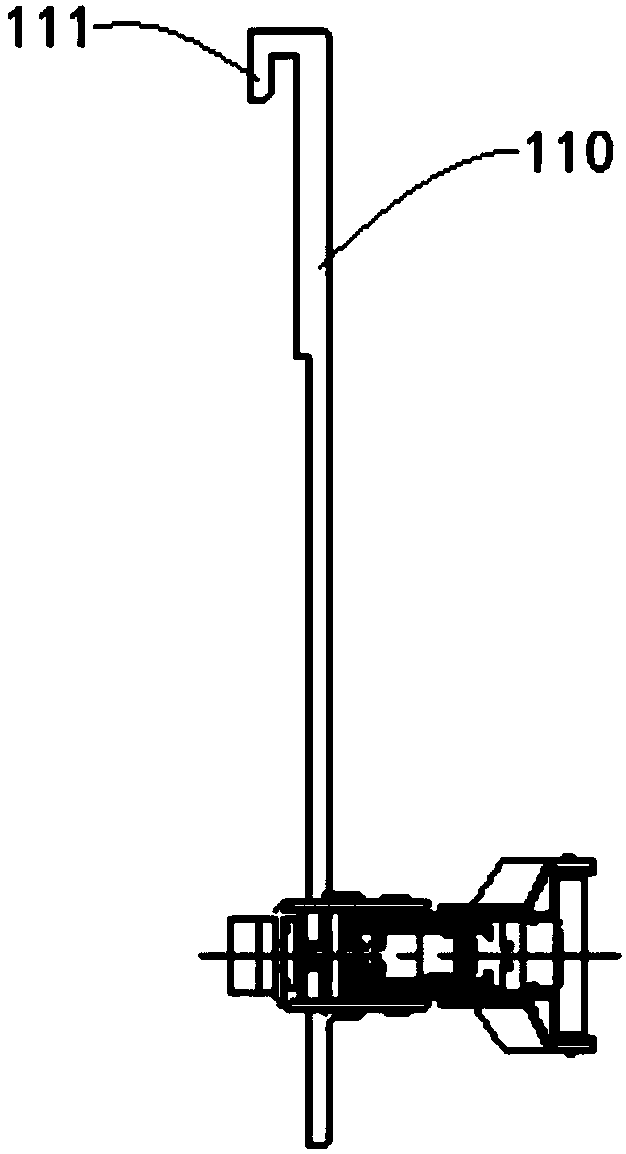

[0042] see Figure 2 to Figure 4 The active part 100 of the cabinet tensioner includes a first suspension plate 110 , a first side plate 120 , two ratchet winch mechanisms 130 , a first locking mechanism 140 and two wire rope guide wheels 150 .

[0043] A hook 111 is arranged on the top of the first suspension plate 110, and the first suspension plate 110 is a plate-shaped structure except for the hook 111. A chute 112, the lowermost end of the first chute 112 is open.

[0044] The first side plate 120 adopts two pieces of 4mm steel plates to be processed by laser cutting and then symmetrically bent to form an L-shape to form a channel steel shape. In the middle of the two groove walls of the first side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap