Belt-type traction means and method for fabricating the traction means as well as use of said traction means in an elevator and an elevator provided with said traction means

A traction device and elevator technology, applied to belt traction devices, can solve problems such as wear and elongation minimization, and achieve the effects of increased service life, reduced size, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

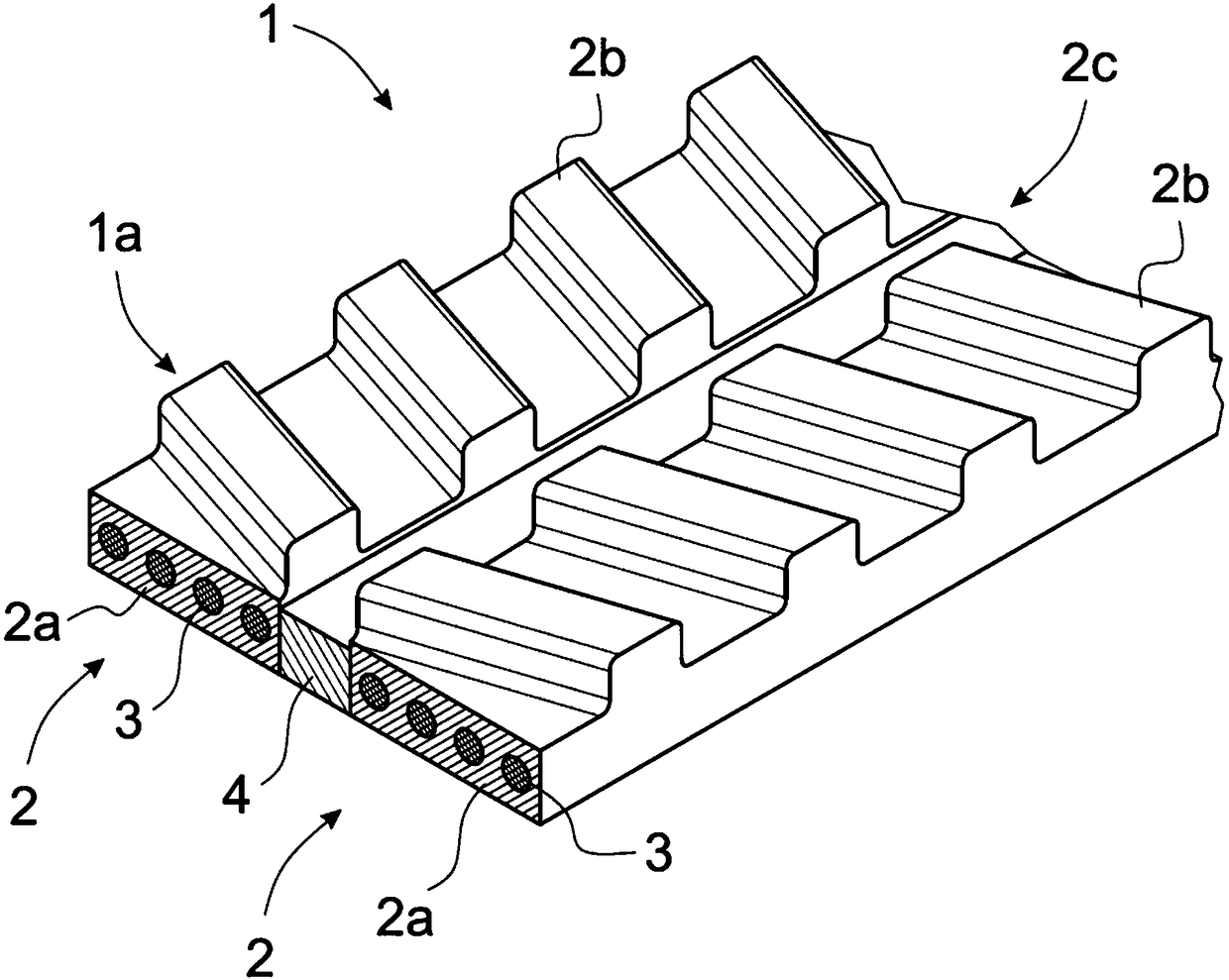

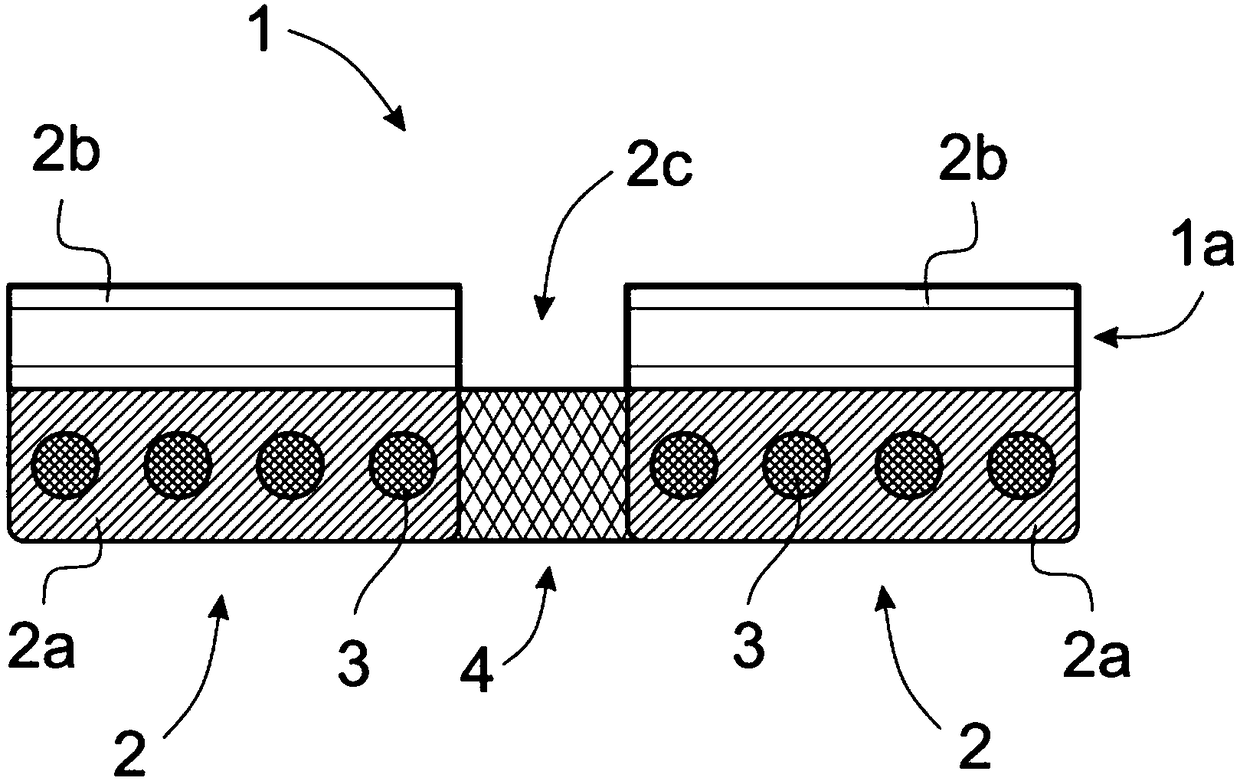

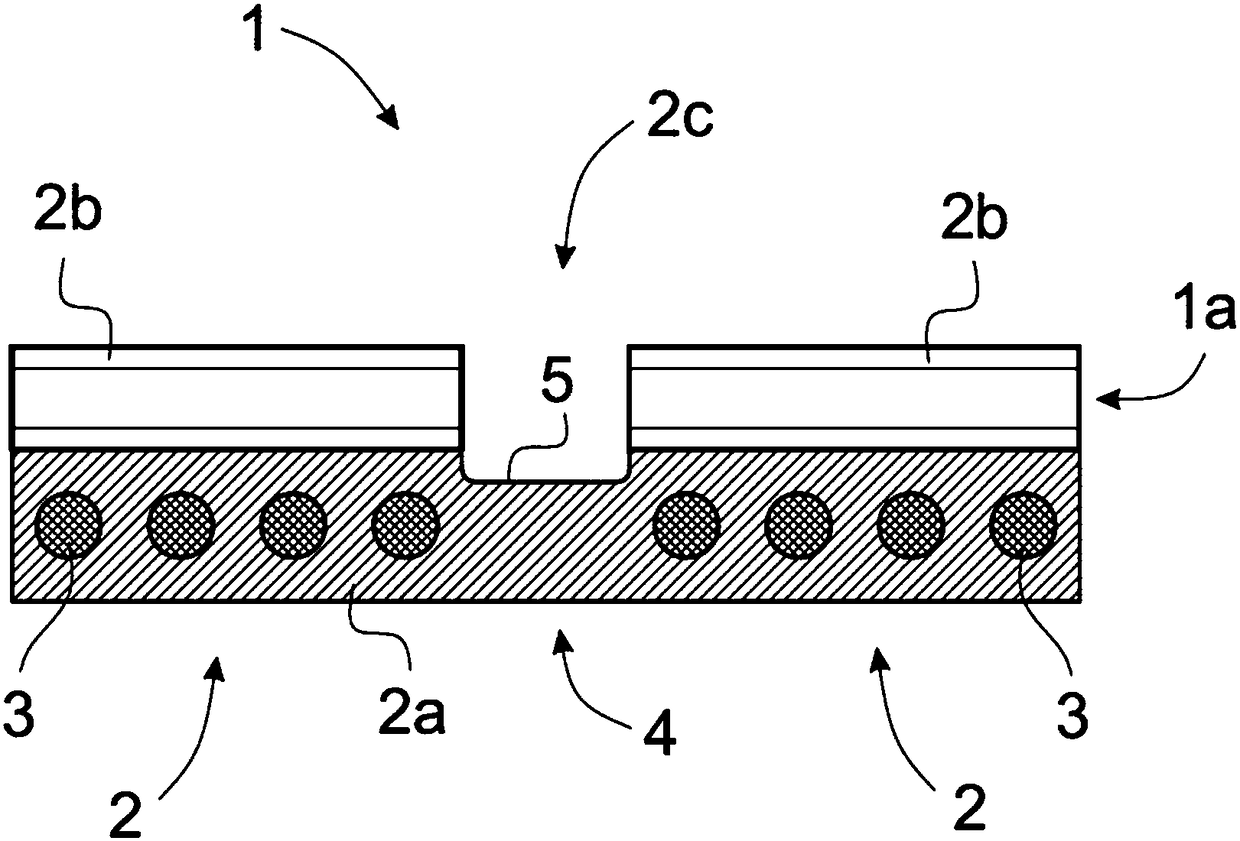

[0015] Figures 1 to 3 Simplified cross-sectional views of various herringbone toothed belts according to the invention are shown, which are used as traction means 1 . All the different toothed belts 1 have in common that in the cross-sectional direction of the toothed belt 1 , ie in the width direction, the edge part 2 with the teeth 2 b is reinforced to withstand forces in the longitudinal and transverse directions of the toothed belt 1 Force, while in the cross-sectional direction, the toothless central part 4 in the center of the toothed belt 1 between the side edges 2 is arranged to bend more than the edge parts 2 of the toothed belt 1 at least in the transverse direction of the toothed belt 1 . In this case, the spring constant of the central part 4 between and connecting the edge parts 2 in the transverse direction of the toothed belt 1 is smaller than the corresponding spring constant of the edge parts 2 .

[0016] At the central part 4 there are no teeth 2b, so in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com