Stirring and extracting tank, and device and method for separating and extracting animal byproducts

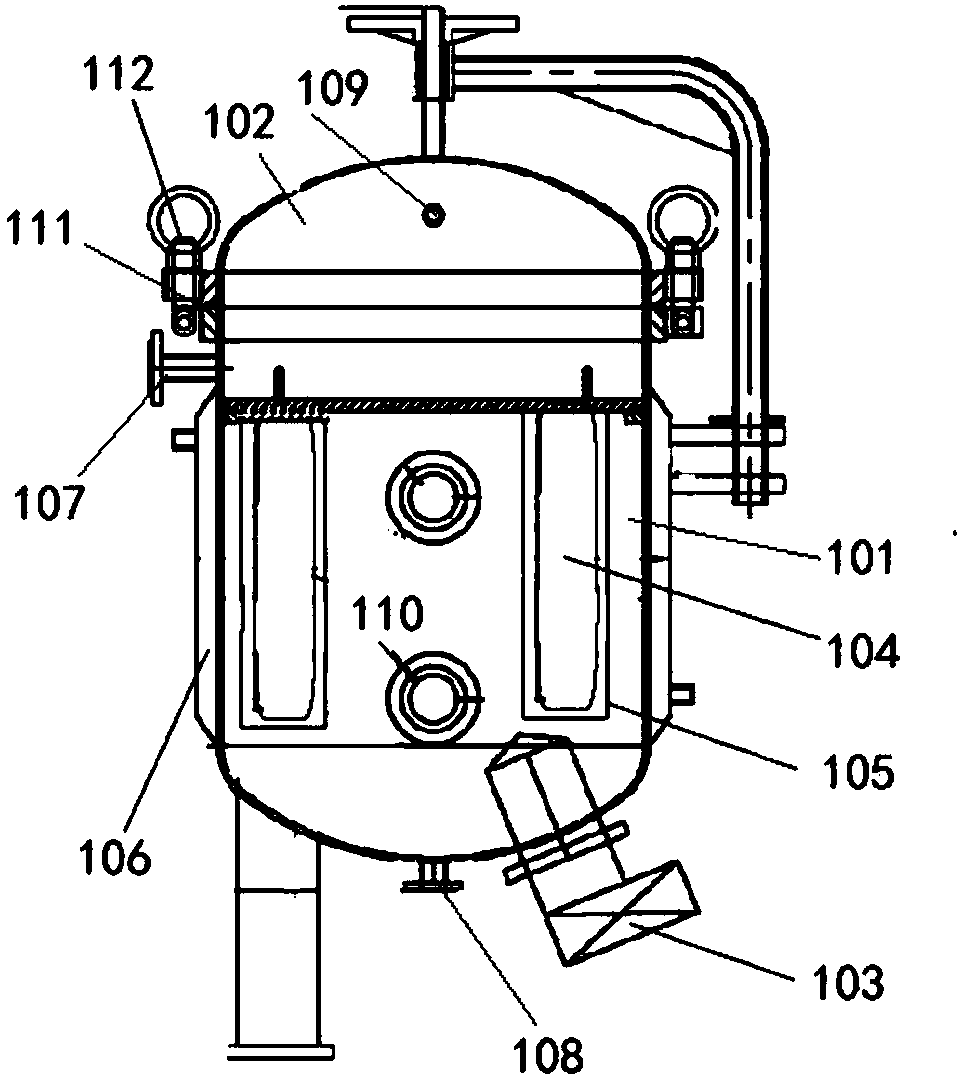

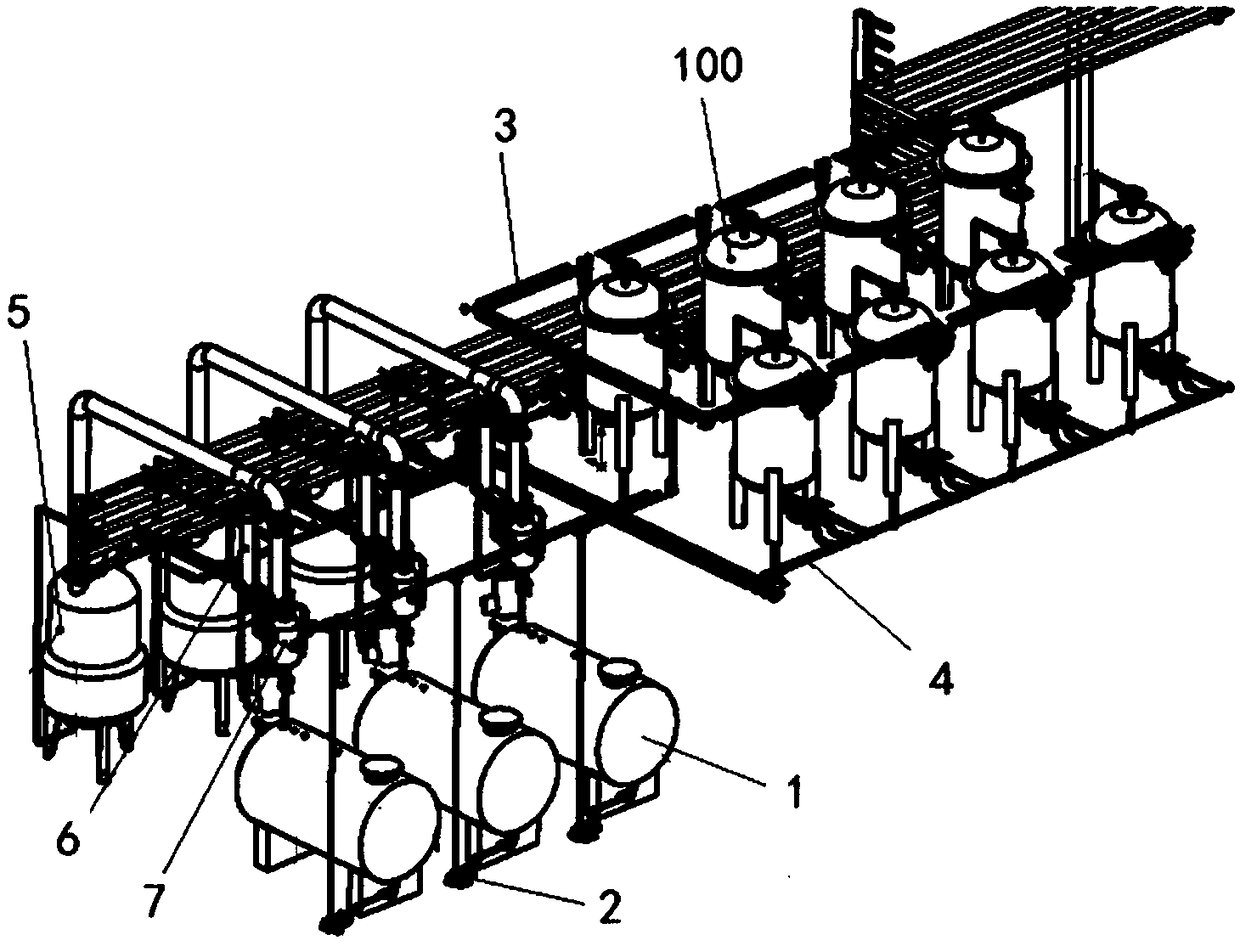

An extraction tank and by-product technology, applied in the fields of animal by-product separation and extraction, animal by-product separation and extraction device, and stirring extraction tank, can solve the problems of solvent volatilization, solvent contamination of solvent, waste of working hours, etc., so as to avoid clogging of filter screen and reduce contact pollution. , The effect of reducing leakage and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The animal by-product separation and extraction method provided by the present invention uses the above-mentioned animal by-product separation and extraction device, and the animal by-product separation and extraction method includes:

[0084] Step 101, adding animal by-products to the filter in the stirring extraction tank, and adding the first solvent in the first solvent storage tank into the stirring extraction tank;

[0085] Step 102, turning on the agitator to stir the first solvent;

[0086] Step 103, when the concentration of the first solvent reaches a preset value after the first extract is separated from the animal by-products and blended into the first solvent, the stirring is stopped;

[0087] Step 104, discharging the solvent in the stirring extraction tank into the first vacuum concentration tank through the solvent outlet, and keeping the stirring extraction tank in communication with the first vacuum concentration tank;

[0088] Step 105, vacuumize the s...

Embodiment 2

[0094] The animal by-product separation and extraction method provided by the present invention uses the above-mentioned animal by-product separation and extraction device, and the animal by-product separation and extraction method includes:

[0095] Step 201, adding animal by-products to the filter in the stirring extraction tank, and adding the first solvent in the first solvent storage tank into the stirring extraction tank;

[0096] Step 202, turning on the agitator to stir the first solvent;

[0097] Step 203, when the concentration of the first solvent reaches a preset value after the first extract is separated from the animal by-products and blended into the first solvent, the stirring is stopped;

[0098] Step 204, discharging the solvent in the stirring extraction tank into the first vacuum concentration tank through the solvent outlet, and keeping the stirring extraction tank in communication with the first vacuum concentration tank;

[0099] Step 205, vacuumize the...

Embodiment 3

[0112] The animal by-product separation and extraction method provided by the present invention uses the above-mentioned animal by-product separation and extraction device, and the animal by-product separation and extraction method includes:

[0113] Step 301, adding animal by-products to the filter in the stirring extraction tank, and adding the first solvent in the first solvent storage tank into the stirring extraction tank;

[0114] Step 302, turning on the agitator to stir the first solvent;

[0115] Step 303, when the concentration of the first solvent reaches a preset value after the first extract is separated from the animal by-products and blended into the first solvent, the stirring is stopped;

[0116] Step 304, discharging the solvent in the stirring extraction tank into the first vacuum concentration tank through the solvent outlet, and keeping the stirring extraction tank in communication with the first vacuum concentration tank;

[0117] Step 305, vacuumize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com