Polyionic liquid base micropore quasi solid state electrolyte preparation method and application

A technology of polyionic liquid and ionic liquid, which is applied in the field of solid electrolyte preparation technology, can solve the problems of increasing battery short circuit, reducing polymer mechanical strength, and difficulty in battery packaging, and achieves the advantages of reducing leakage and volatilization, not easy to leak, and improving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

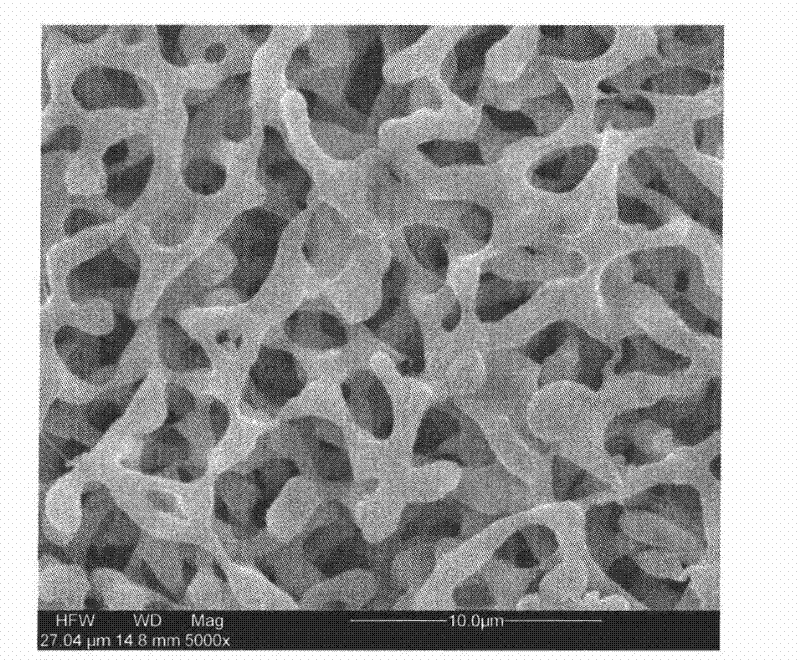

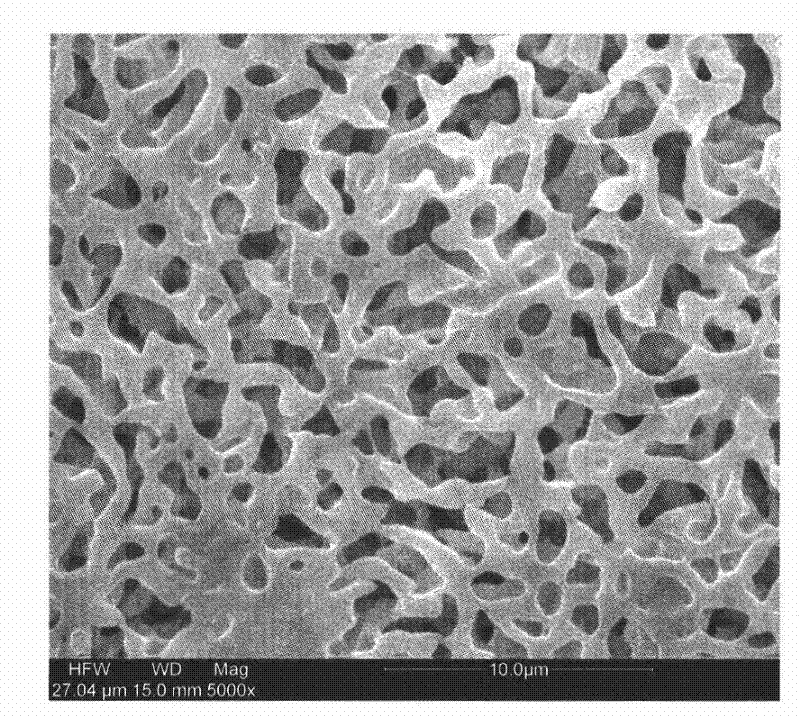

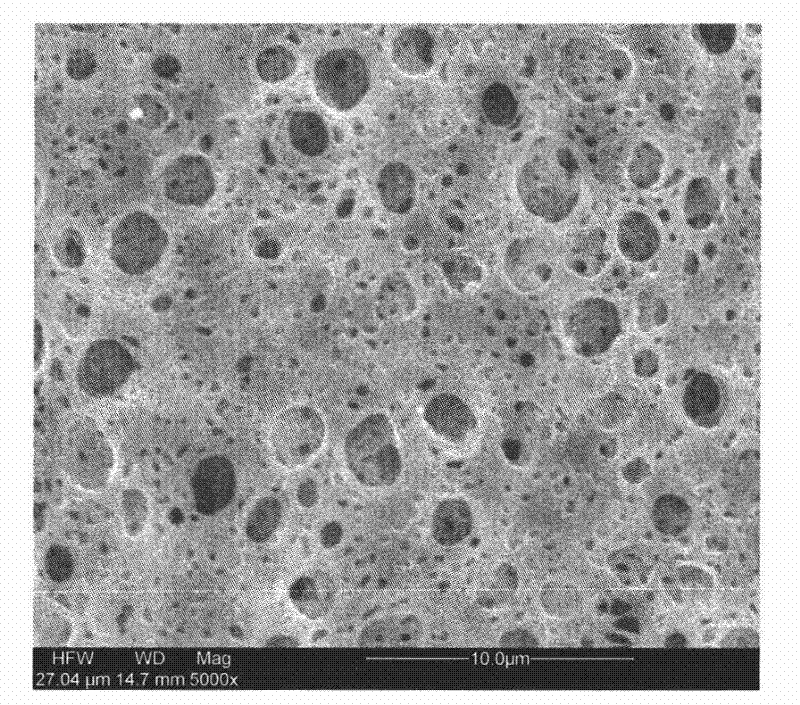

Image

Examples

Embodiment 1

[0025] In the first step, weigh 1 mol of N-vinylimidazole and 1 mol of 1-iodopropane, mix them uniformly, put them into a polytetrafluoroethylene-lined reaction kettle, seal the reaction kettle and heat up. Take out the autoclave after heat preservation at 120°C for 4h; after the autoclave is cooled to room temperature, take out the product, wash off the excess iodoalkane with ether solvent, and then vacuum dry at 80°C for 24h to remove the residual ether solvent to obtain 1-vinyl-3- Propimidazolium iodine salt.

[0026] Second step, take by weighing 5g 1-vinyl-3-propylimidazolium iodide salt, be dissolved in 10ml ethanol solvent, add 2wt% azobisisobutyronitrile as initiator, N 2 Polymerization was carried out at 60°C for 30 hours under protection, and the product was vacuum-dried at 80°C for 24 hours to remove the ethanol solvent to obtain a polymerized ionic liquid.

[0027] The third step is to weigh 0.1g of polymerized ionic liquid, 0.9g of polyvinylidene fluoride, and 1....

Embodiment 2

[0031] In the first step, weigh 1 mol of N-vinylimidazole and 1.2 mol of 1-iodopropane, mix them evenly, put them into a polytetrafluoroethylene-lined reactor, seal the reactor and heat up. Take out the autoclave after heat preservation at 100°C for 6h; after the autoclave is cooled to room temperature, take out the product, wash off the excess iodoalkane with ether solvent, and then vacuum dry at 80°C for 24h to remove the residual ether solvent to obtain 1-vinyl-3- Propimidazolium iodine salt.

[0032] Second step, take by weighing 10g 1-vinyl-3-propylimidazolium iodide salt, be dissolved in 25ml ethanol solvent, add 6wt% azobisisobutyronitrile as initiator, N 2 Polymerize at 80°C for 10 hours under protection, and vacuum dry the product at 80°C for 24 hours to remove the ethanol solvent to obtain a polymerized ionic liquid.

[0033]The third step is to weigh 0.3g of polymerized ionic liquid, 0.7g of polyvinylidene fluoride, and 0.45g of glycerin and dissolve them in 20g of...

Embodiment 3

[0037] In the first step, weigh 1 mol of N-vinylimidazole and 1.5 mol of 1-iodopropane, mix them uniformly, put them into a reaction kettle lined with polytetrafluoroethylene, seal the reaction kettle and heat up. Take out the autoclave after heat preservation at 70°C for 8 hours; after the autoclave is cooled to room temperature, take out the product, wash off excess iodoalkane with ether solvent, and then vacuum dry at 80°C for 24 hours to remove residual ether solvent to obtain 1-vinyl-3- Propimidazolium iodine salt.

[0038] Second step, take by weighing 15g 1-vinyl-3-propylimidazolium iodide salt, be dissolved in 45ml ethanol solvent, add 10wt% azobisisobutyronitrile as initiator, N 2 Polymerize at 70° C. for 24 hours under protection, and vacuum-dry the product at 80° C. for 24 hours to remove the ethanol solvent to obtain a polymerized ionic liquid.

[0039] The third step is to weigh 0.6g of polymerized ionic liquid, 0.4g of polyvinylidene fluoride, and 0.9g of glycer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com