Sewage treatment system

A sewage treatment system and sedimentation tank technology, applied in sedimentation tanks, chemical instruments and methods, separation methods, etc., can solve the problems of poor efficiency, poor scraping effect, large resistance, etc., and achieve long service life, easy replacement, and difficult wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

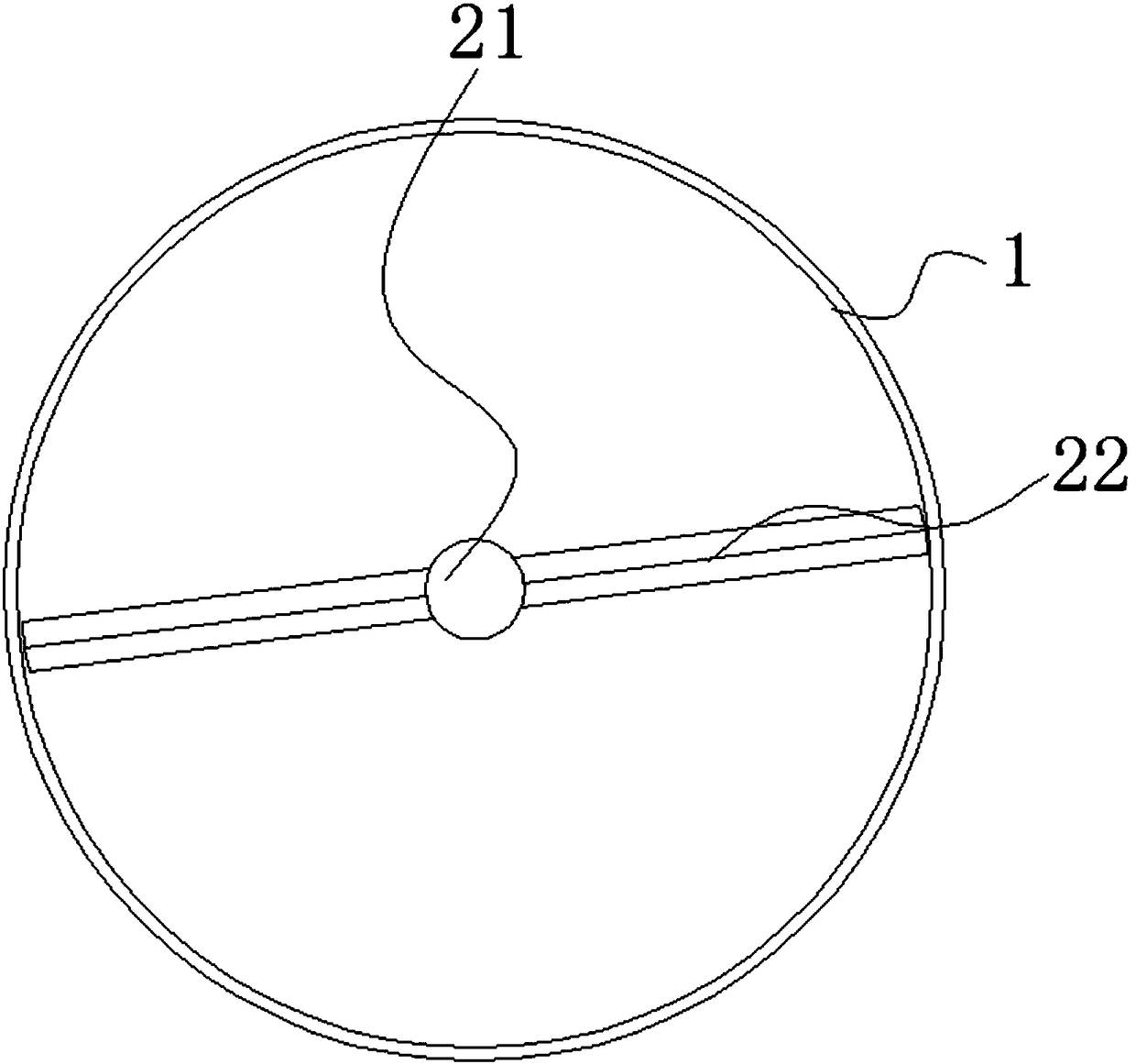

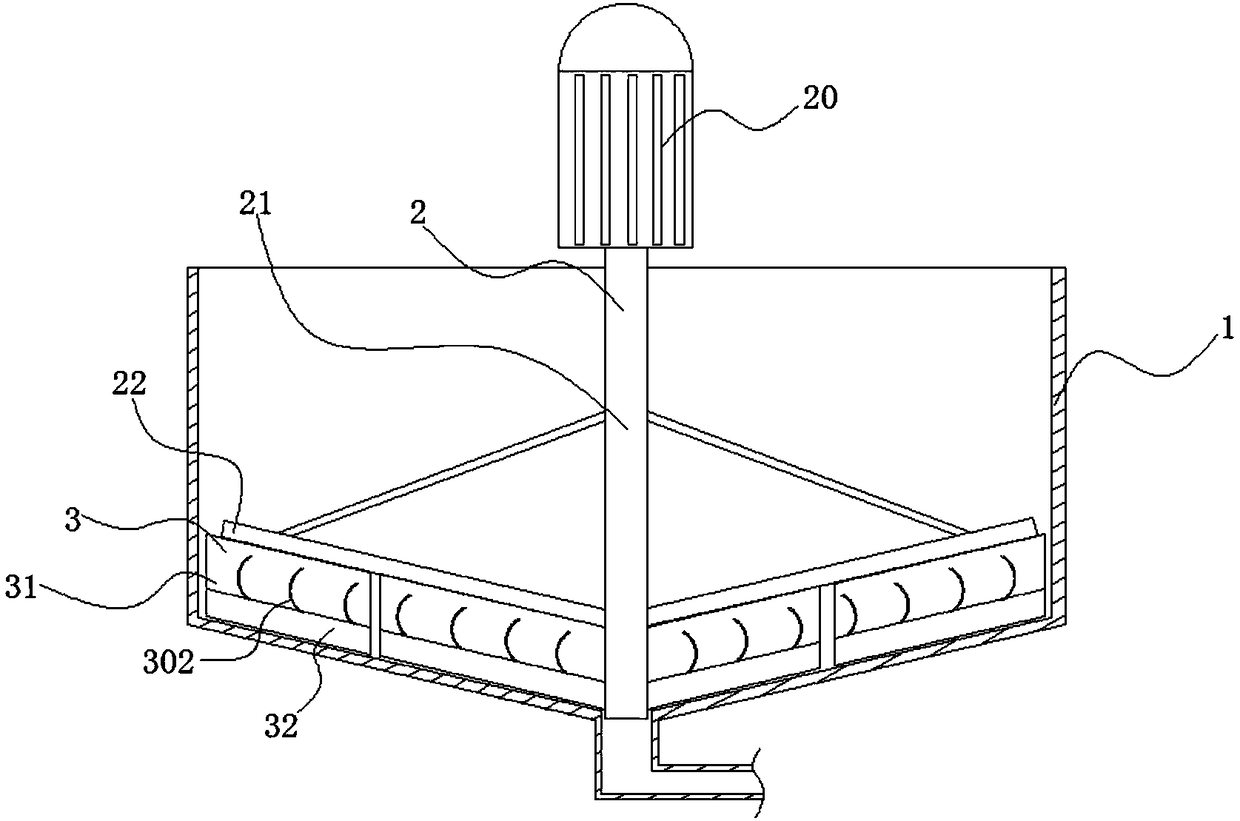

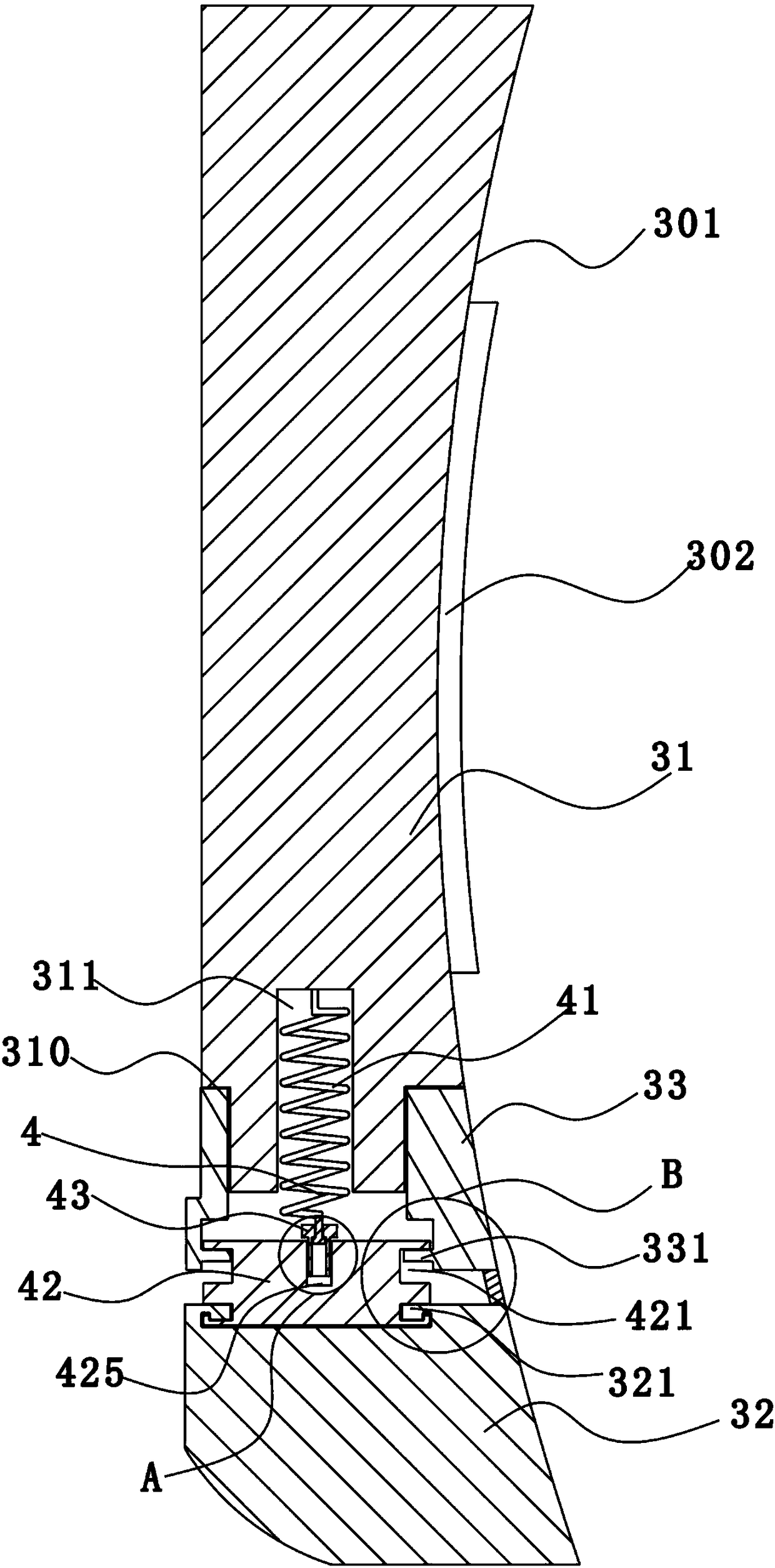

[0021] Such as Figure 1-5 Shown, a kind of sewage treatment system comprises settling tank 1 and mud scraping device 2, and described settling tank 1 is a conical tank, and this settling tank 1 is formed by pouring cement; At the bottom of this settling tank 1 There is a row of mud pipes connected to the center, and the mud scraped by the mud scraping device 2 enters into the mud discharge pipe, and then is discharged through the mud discharge pipe. The specific mud discharge pipe mud discharge is the prior art, so it will not be repeated here; The mud scraping device 2 includes a motor 20, a rotating part 21, a support part 22 and a mud scraping part 3. The rotating part 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com