Movable floating table water surface garbage crushing, separating and compressing system device

A technology of surface garbage and compression system, which is applied in the direction of motor vehicles, transportation and packaging, ships, etc., can solve the problems of slow emergency deployment, low safety factor, and no finishing device, etc., to reduce water flow resistance, high purification efficiency, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

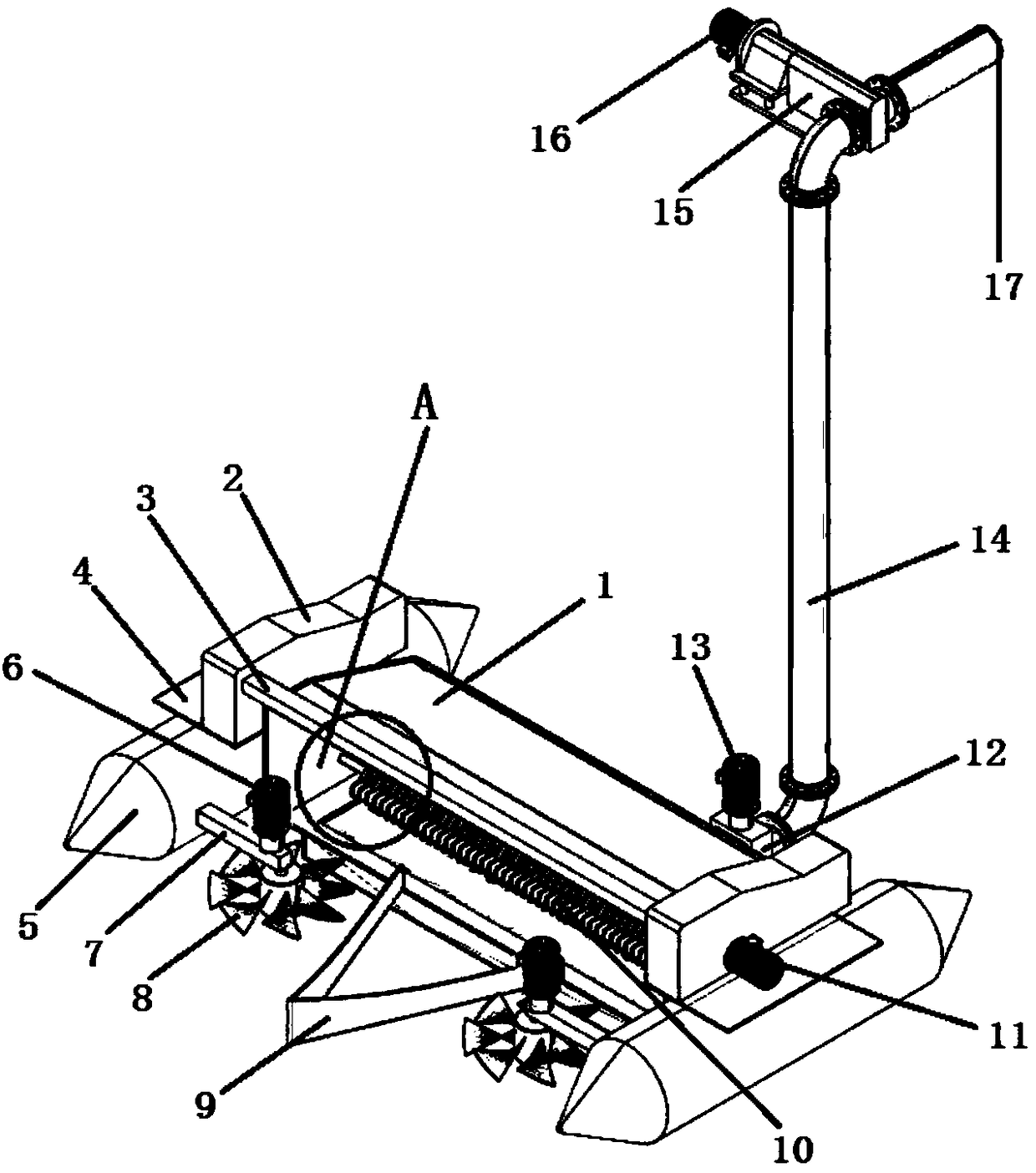

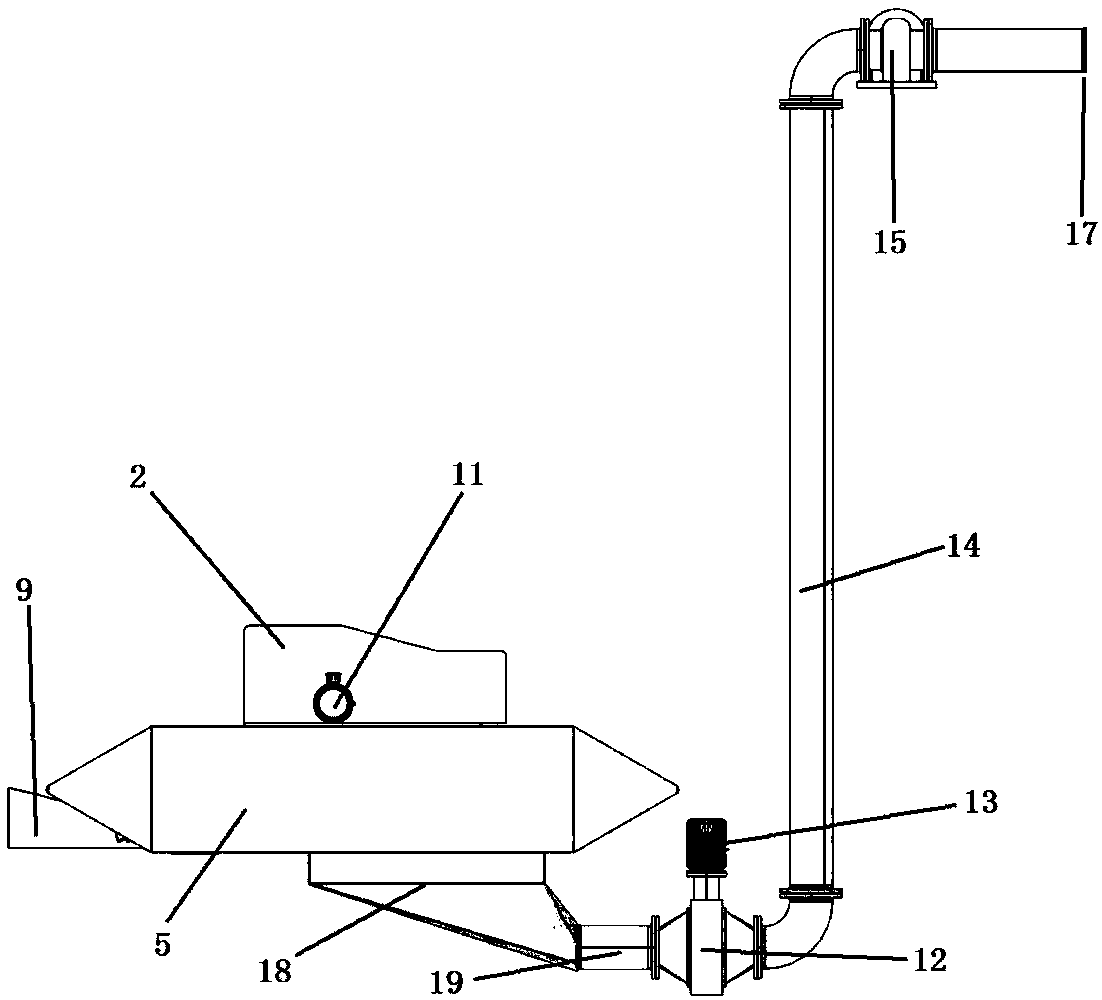

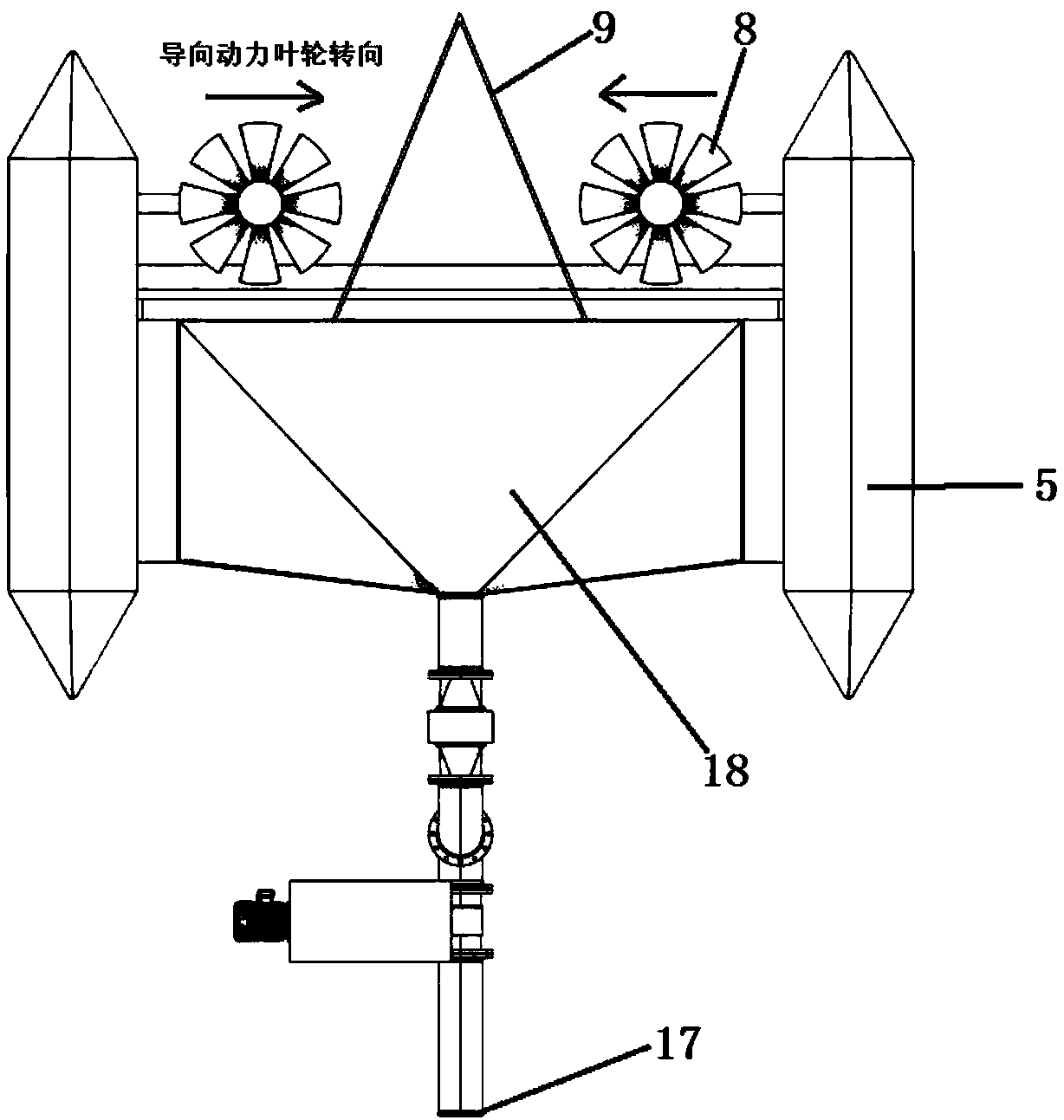

[0026] Embodiment: A mobile floating platform water surface garbage crushing separation compression system device.

[0027] refer to Figure 1 to Figure 4 As shown, a mobile floating platform water surface garbage crushing, separation and compression system device includes: a fixed platform 1; a reduction transmission mechanism 2 welded and installed on both sides of the fixed platform 1, and a crossbeam is installed between the reduction transmission mechanism 2 3. The base 4 of the reduction transmission mechanism installed under the reduction transmission mechanism 2. A suspension device 5 is arranged under the base 4 of the reduction transmission mechanism. The first crushing mechanism 10, the first crushing mechanism 10 includes a second motor 11, a transmission shaft 101, a crushing knife 102 and an isolation gasket 103, the second motor 11 is connected to the transmission shaft 101, and the crushing knife 102 is welded on the transmission On the shaft 101, the spacer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com