Brick and concrete sorting machine

A sorting machine and brick-mixing technology, which is applied in the direction of solid separation, filter screen, grid, etc., can solve separation problems and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

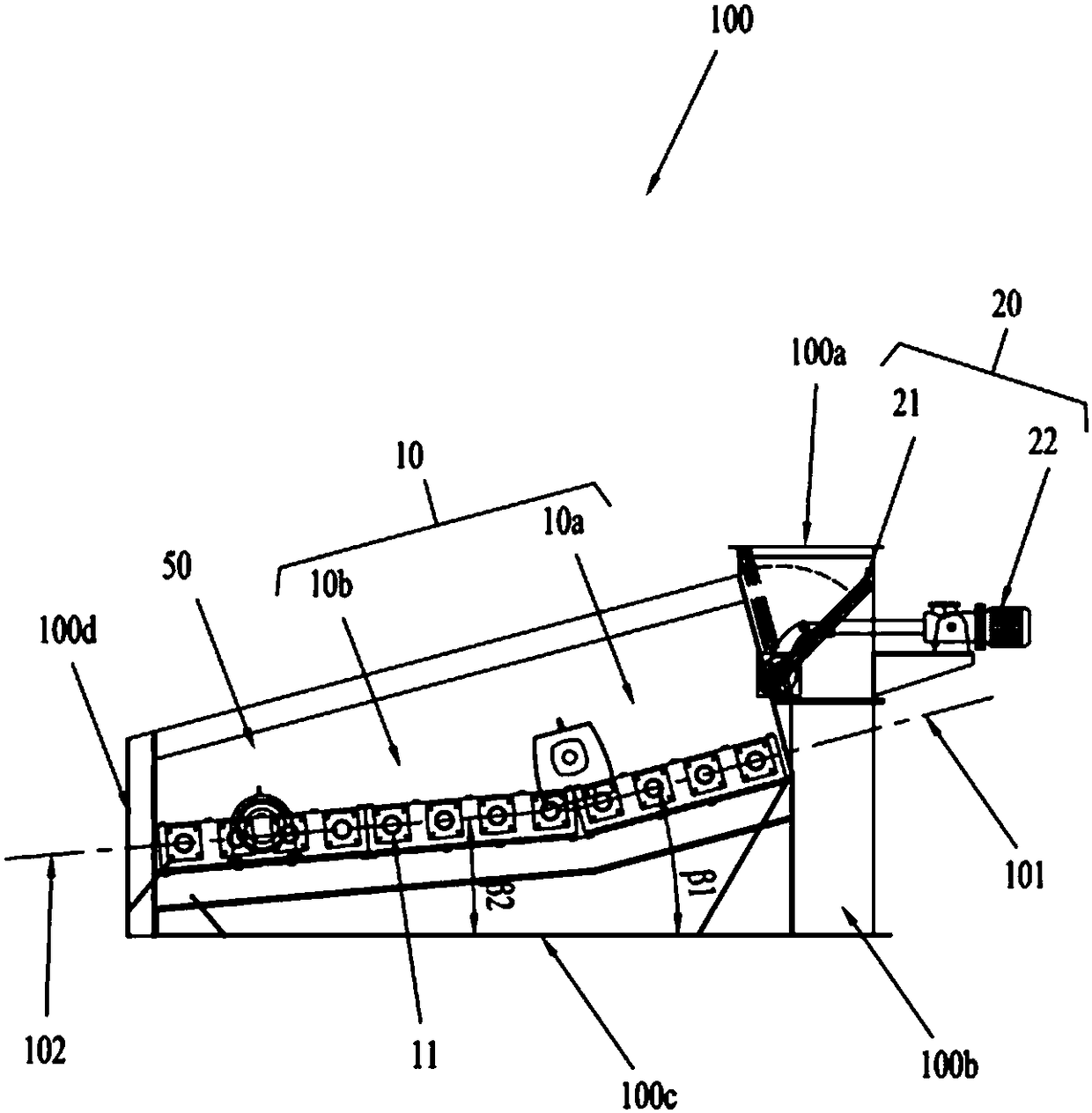

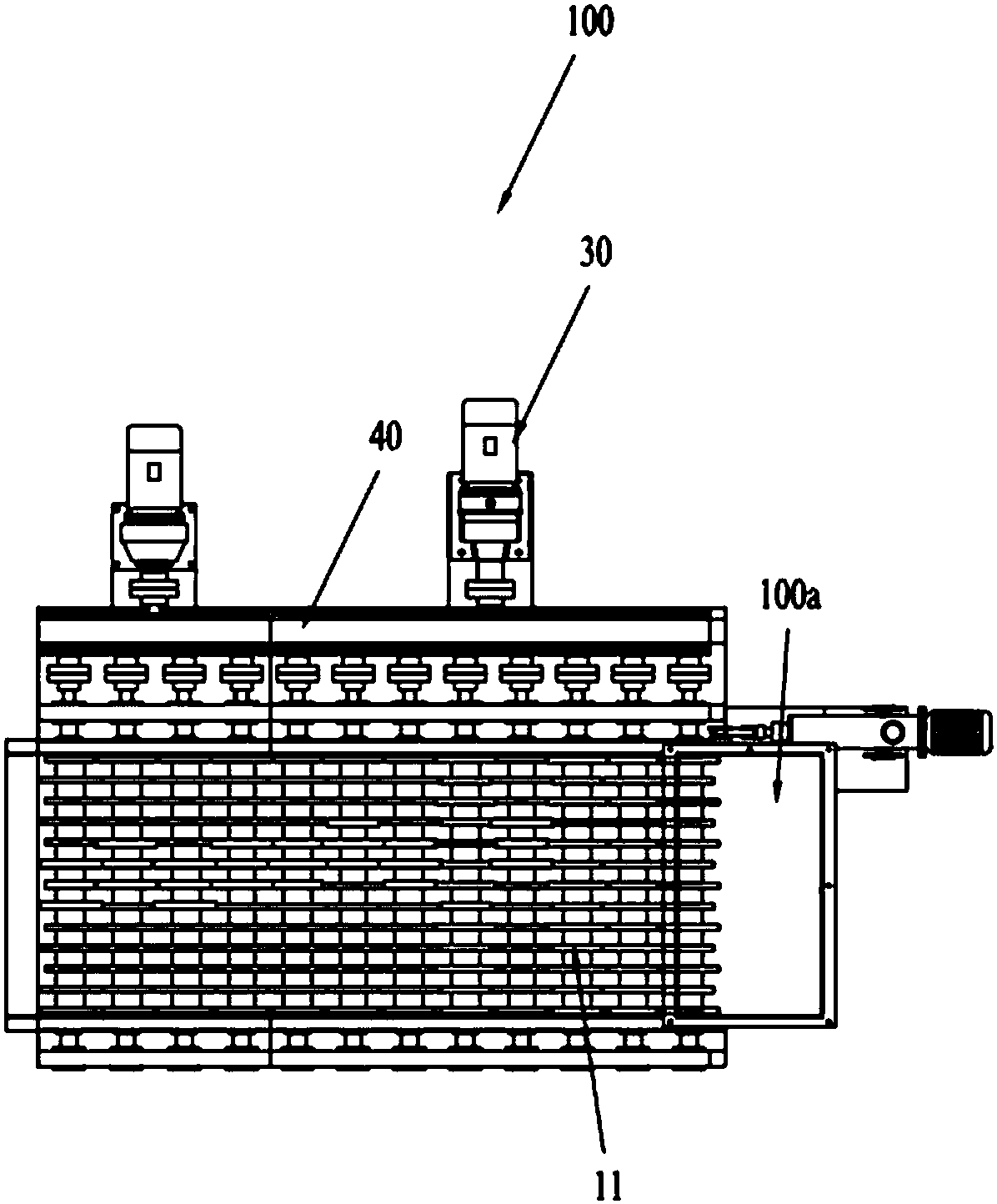

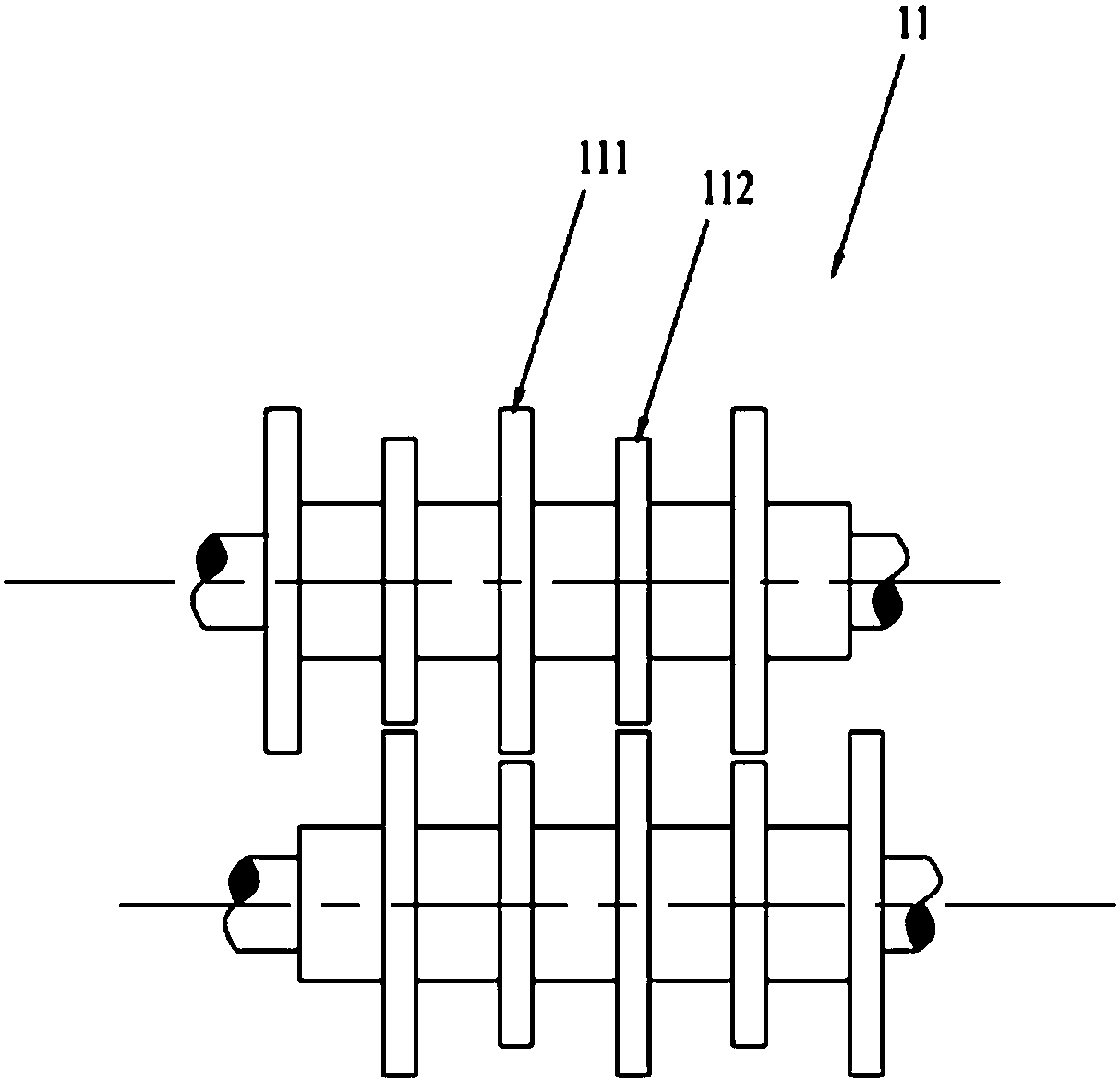

[0027] Such as Figure 1 to Figure 4 As shown, a brick-concrete sorting machine 100 includes: a roller screen 10 for brick-concrete separation; the roller screen 10 includes: adjacent first impeller shaft group 10a and second impeller shaft group 10b; An impeller shaft group 10a includes a plurality of impeller shafts 11 arranged along a first straight line 101; a second impeller shaft group 10b includes a plurality of impeller shafts 11 arranged along a second straight line 102; the clip formed by the first straight line 101 and the ground The angle β1 is greater than the angle β2 formed by the second straight line 102 and the ground; the brick-concrete separator 100 is provided with a feed port 100a for construction waste to enter; the first impeller shaft group 10a is close to the feed port 100a; The axle group 10b is far away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com