Aluminum section cooling passage

A technology of aluminum profile and cooling channel, which is applied in the field of aluminum profile production and processing, can solve the problems of high energy consumption, high installation cost of multiple fans, and high noise, and achieve the effects of rational use of resources, good cooling effect, and reduced installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

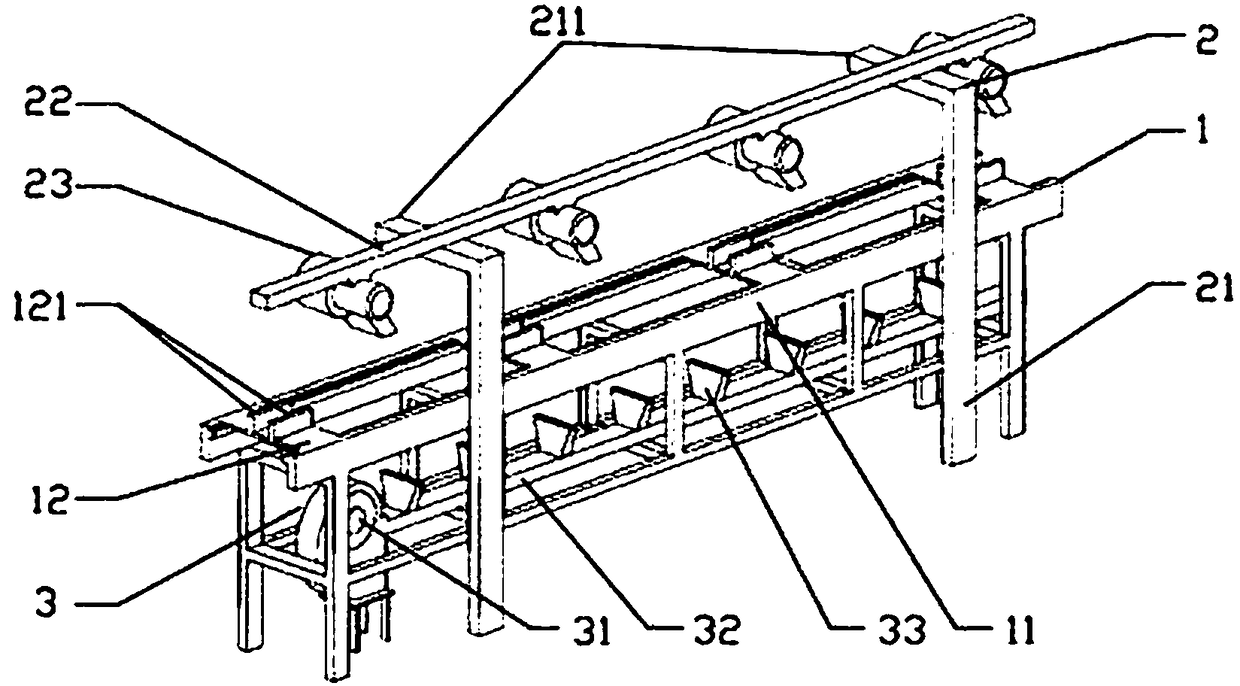

[0020] See figure 1 , an aluminum profile cooling channel, including a feeding frame 1, a stand 2 arranged on the side of the feeding frame 1 and a fan 23 arranged on the stand 2, and a lower cooling device 3 arranged on the feeding frame 1.

[0021] The lower cooling device 3 includes a blower 31 and an air supply mechanism connected to the blower 31 . The air supply mechanism includes an air supply pipe 32 that matches the length of the feeding frame 1 and is closed at one end, and a plurality of air outlet bodies 33 that are connected to the air supply pipe 32 and that are open at one end. .

[0022] The feeding frame 1 includes a frame body 11, a supporting plate 12 arranged on the frame body 11 and having a distance therebetween, and an underframe 12 arranged at the bottom of the frame body 11 for carryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com