Foamed concrete foam mixing device provided with blades

A foamed concrete and blade technology, used in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of damage, inability to meet the needs of use, insufficient bubbles in foamed concrete, etc. The effect of uniform distribution of bubbles and uniform mixing is avoided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

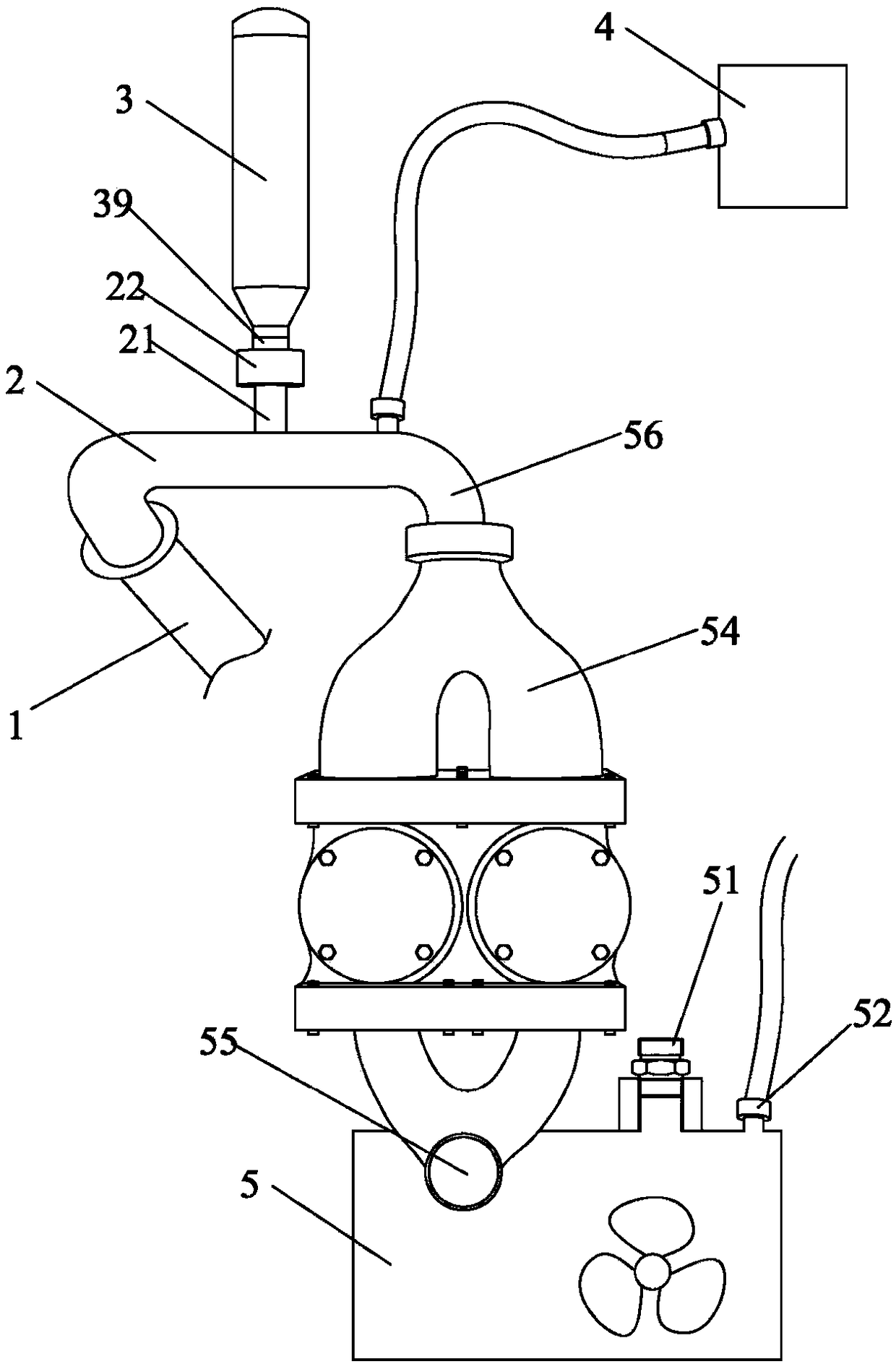

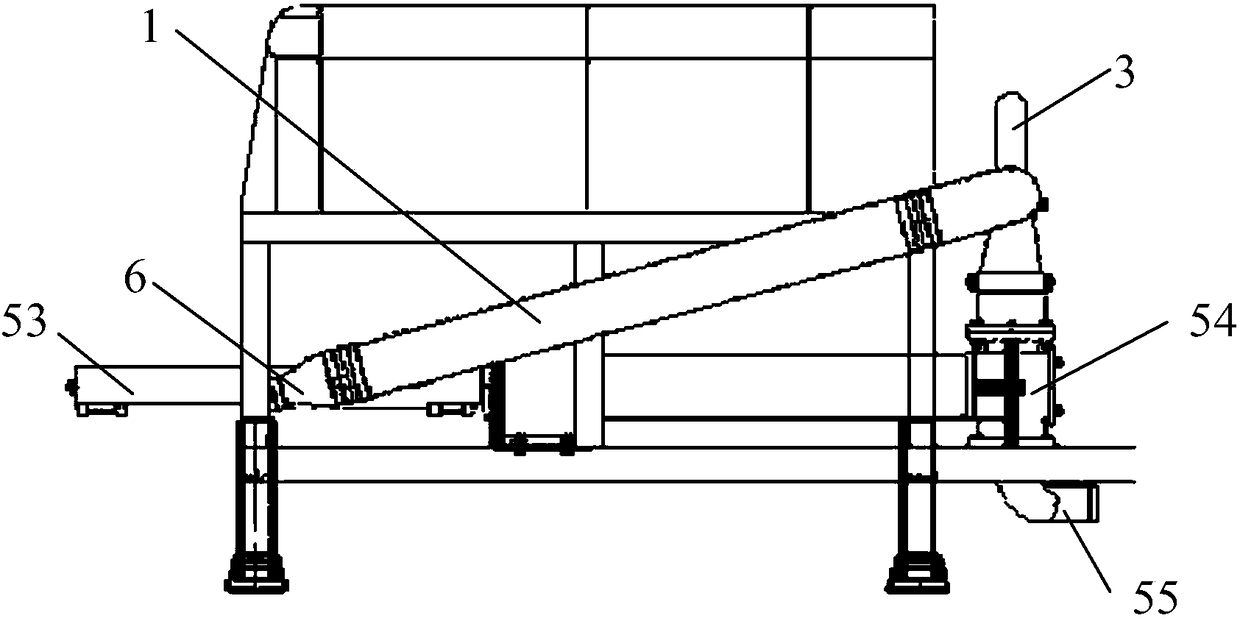

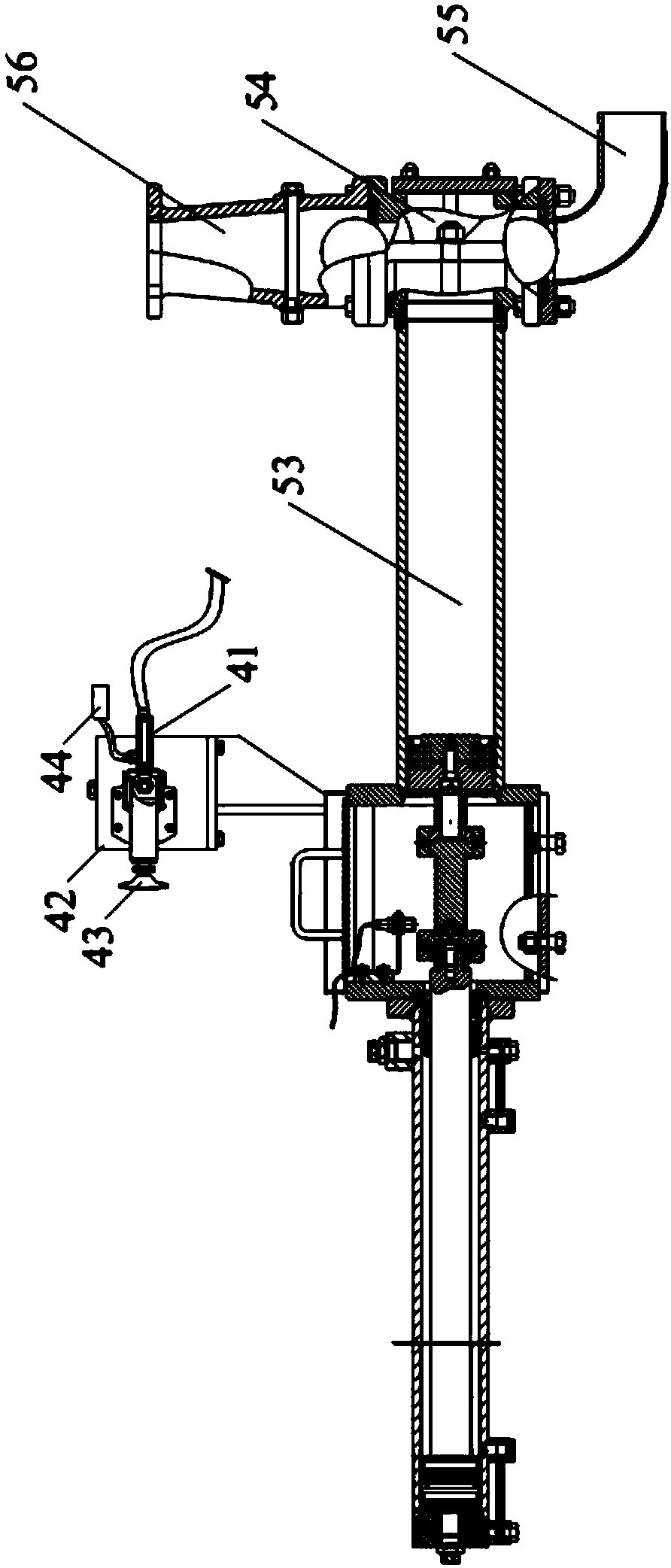

[0029] The present invention discloses a foam concrete mixing device provided with blades, such as Figure 1-7 As shown, it is a preferred embodiment of the present invention, such as Figure 1-2 As shown, it includes a preliminary mixing pipeline 2 and a conveying device 1, wherein the front end of the preliminary mixing pipeline 2 is connected with a foam generating mechanism 4 and a cement slurry mixing mechanism 5, and the rear end 2 of the preliminary mixing pipeline is connected with the front end of the conveying device 1, and the conveying device 1 The rear end is connected to the foamed concrete output mechanism 6, and the foamed concrete output mechanism 6 is not the protection point of the present invention, and it can be a common mechanism in the industry, such as a delivery hose, an output nozzle, etc. The foam generator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com