Frame type hydraulic spare tire support

A frame-type, hydraulic technology, applied in spare tire arrangement, transportation and packaging, vehicle parts, etc., can solve the problem of high center height in the height direction of the spare tire bracket, easy breakage of the rocker arm, cumbersome disassembly and assembly, etc., to avoid rigid contact , low cost, good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

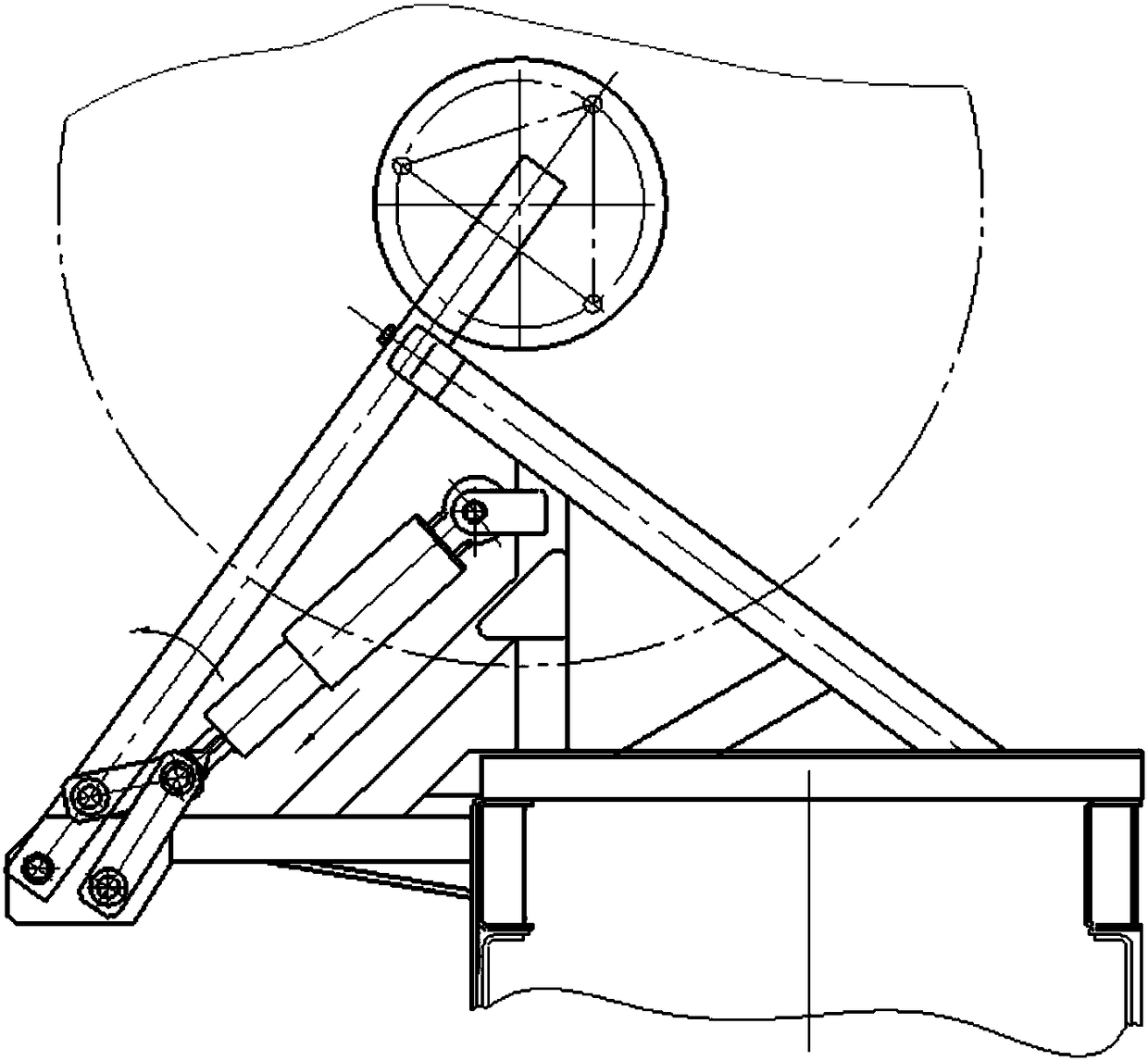

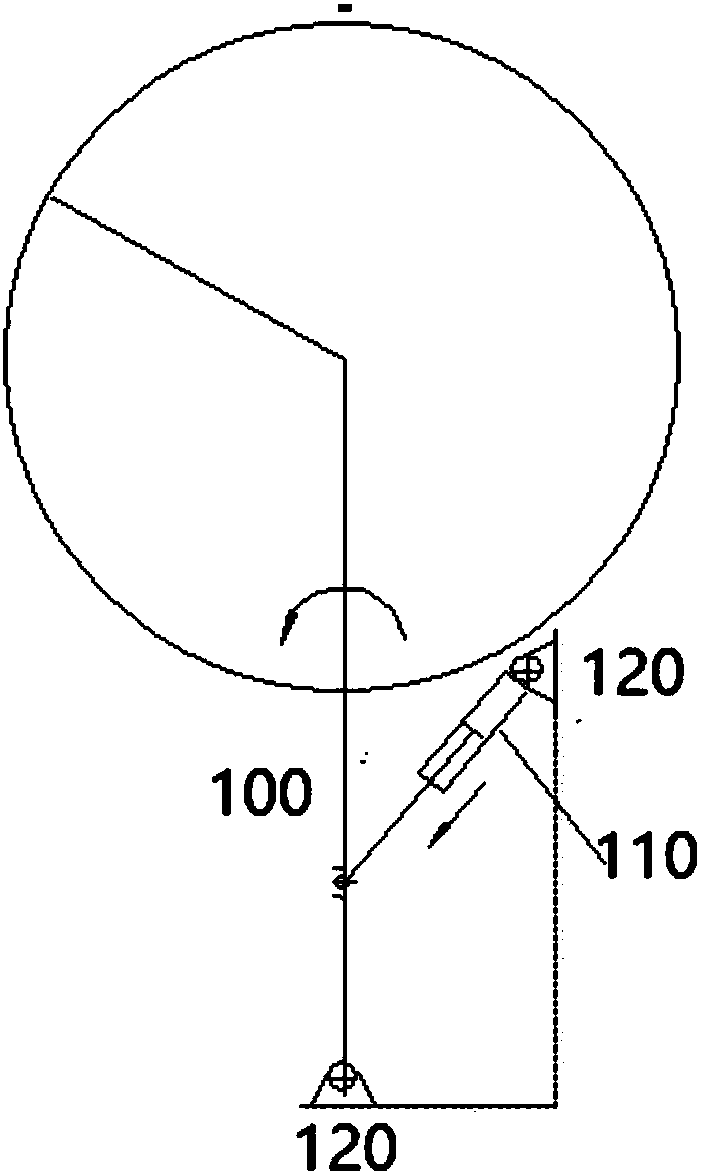

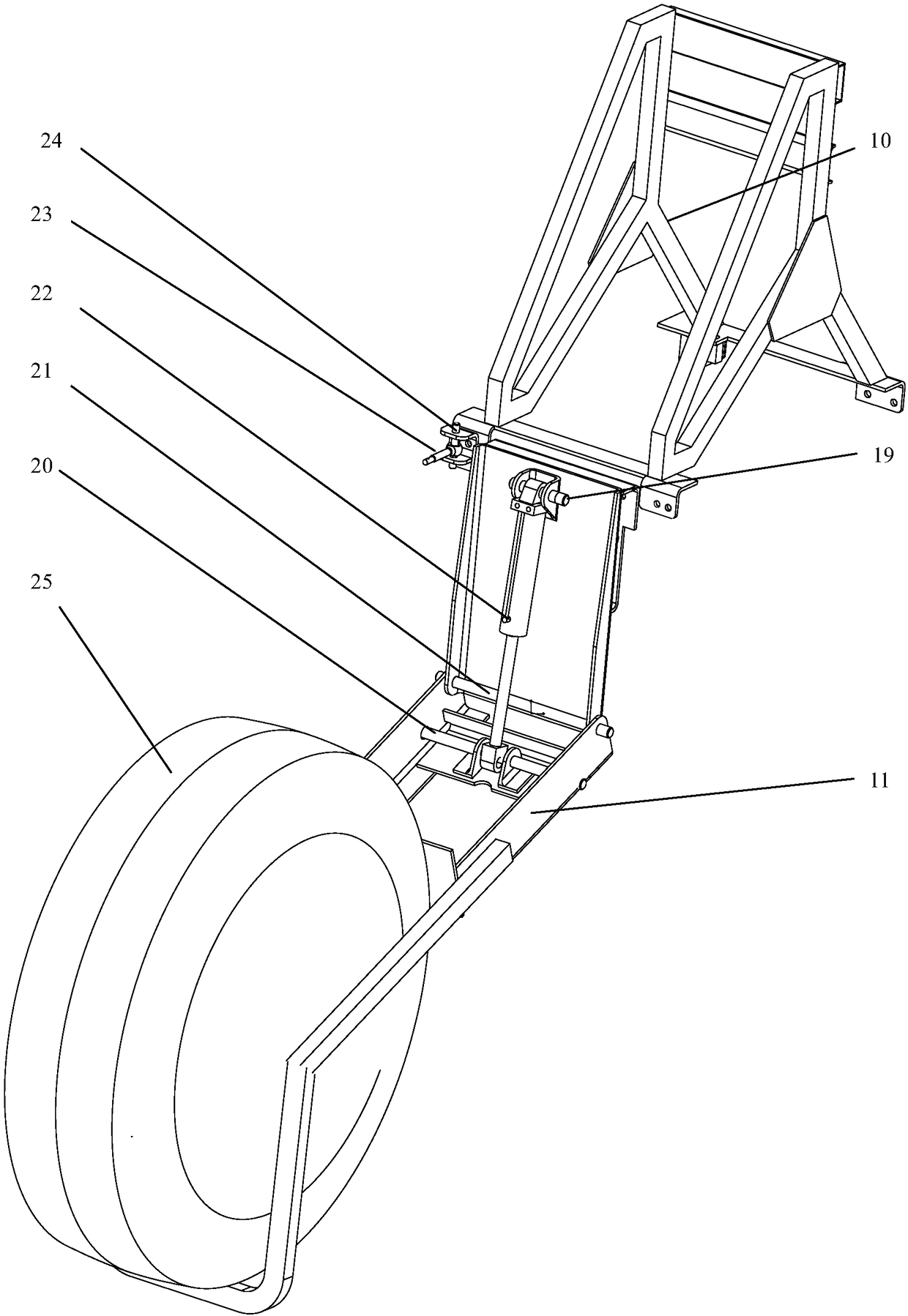

[0030] A frame-type hydraulic spare tire support of the present invention includes a frame assembly 10, an overturning arm assembly 11, an upper pin 19, a lower pin 20, a hinge pin 21, a tipping cylinder 22, a locking bolt 23, a lock Pin shaft 24, locking nut 26. Such as image 3 As shown, tire 25 is also shown in the figure.

[0031] Such as Figure 4 As shown, the structure of the frame assembly 10 is complicated and the specific structure is as follows: by the left frame 1, the upper baffle plate 2, the middle baffle plate 3, the right frame 4, the rear angle steel 5, the front angle steel 6, the U-shaped piece 7, the U-shaped plate 8, U-shaped locking seat 9 forms. Both the left frame 1 and the right frame 4 are composed of square tubes, and its shape is an upside-down "letter Y" shape, while the vertical line of the upside-down "letter Y" shape and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com