Assembled mortise and tenon structure with diagonal braces

A prefabricated, tenon-and-mortise technology, used in building components, building structures, protective buildings/shelters, etc., can solve the problems of inability to withstand earthquake shocks, overall structural damage, complex styles, etc., and achieve easy assembly and assembly. Quick and easy, style-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

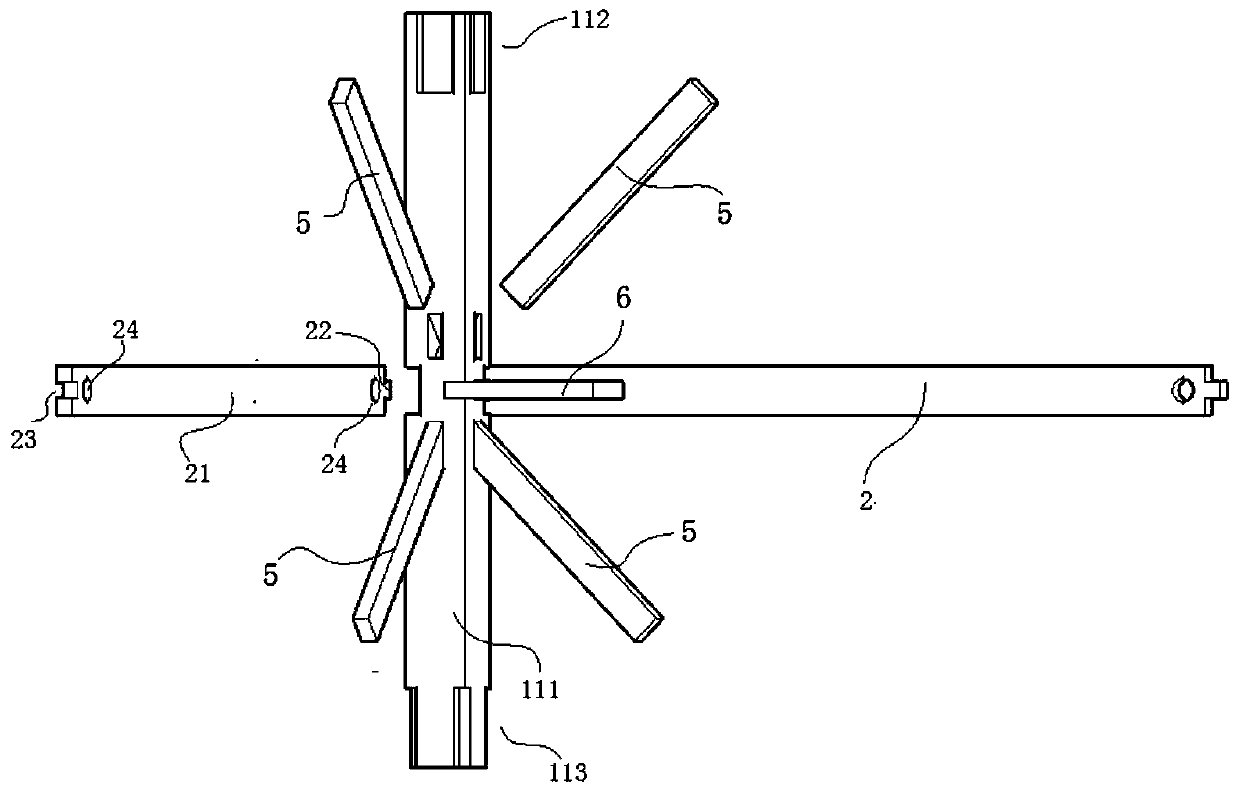

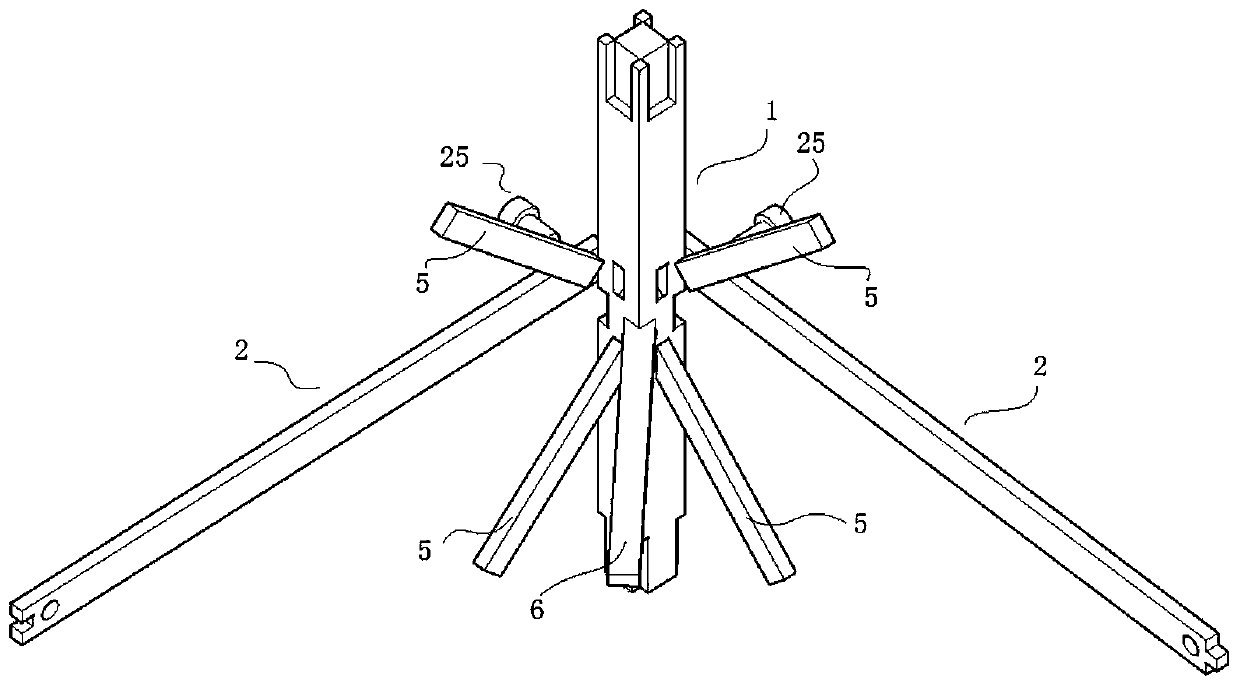

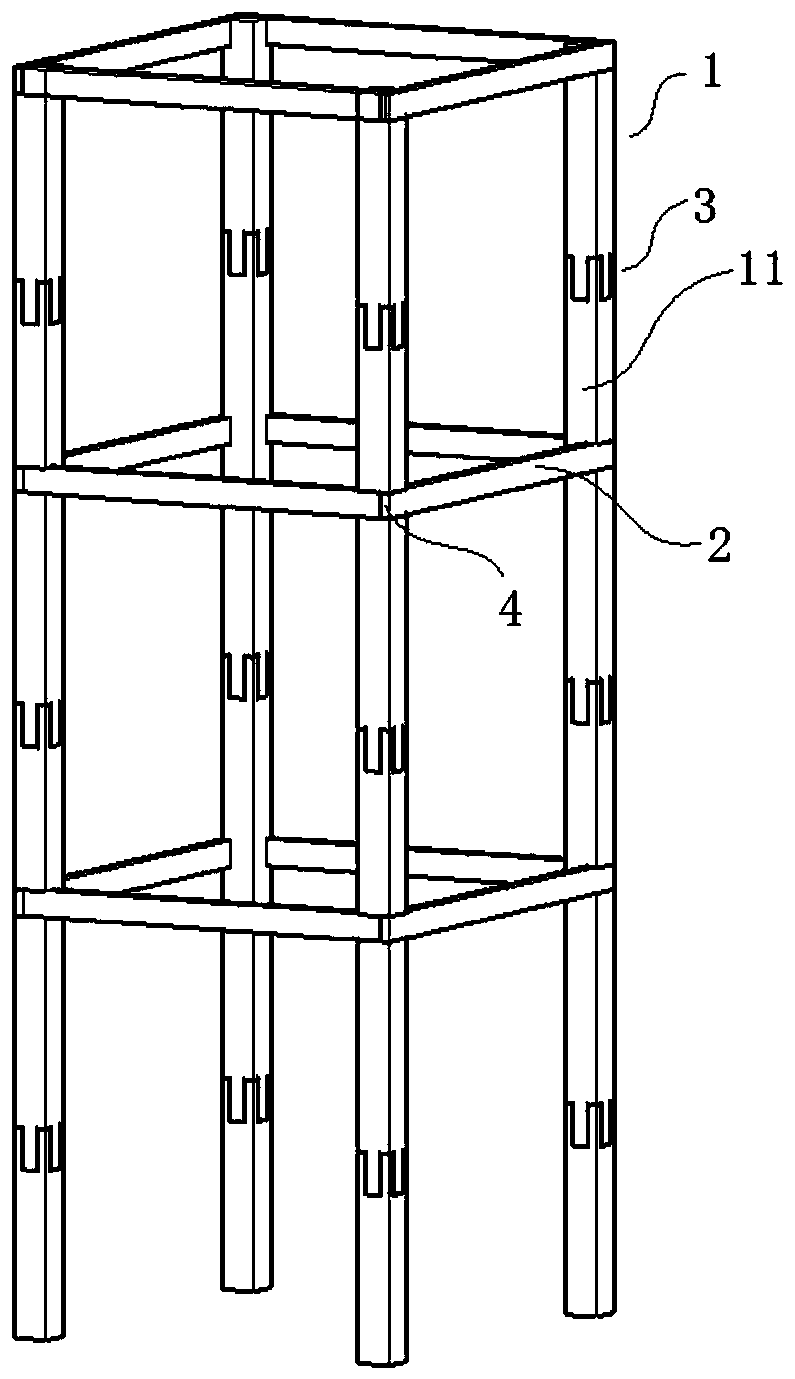

[0036] An assembled mortise and tenon structure with diagonal braces, such as Figure 1-10 As shown, it is a beam-column frame structure, including a plurality of column structures 1 and a plurality of unit beams 2 for connecting the column structures 1, vertical diagonal braces 5 and horizontal diagonal braces 6, and the column structure 1 is formed by the first tenon The mortise and tenon joints 3 are composed of unit columns 11 connected end to end, and the unit beam 2 is embedded between two adjacent column structures 1 through the second mortise and tenon joint 4 .

[0037] Among them, such as Figure 5-7 As shown, the unit column 11 is composed of a column body 111, a first insertion column 112 connected to one end of the column body 111, and a second insertion column 113 connected to the other end of the column body 111. The first mortise and tenon joint 3 consists of a column structure The first plug-in post 112 and the second plug-in post 113 of two adjacent unit pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com