S-shaped perforated plate

A perforated plate and side plate technology, applied in the field of sound-absorbing materials for building decoration, can solve the problems of no sound source design, unsatisfactory sound-absorbing effect, lack of directional structure of sound-absorbing plates, etc., so as to increase the sound resistance and reduce the sound intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

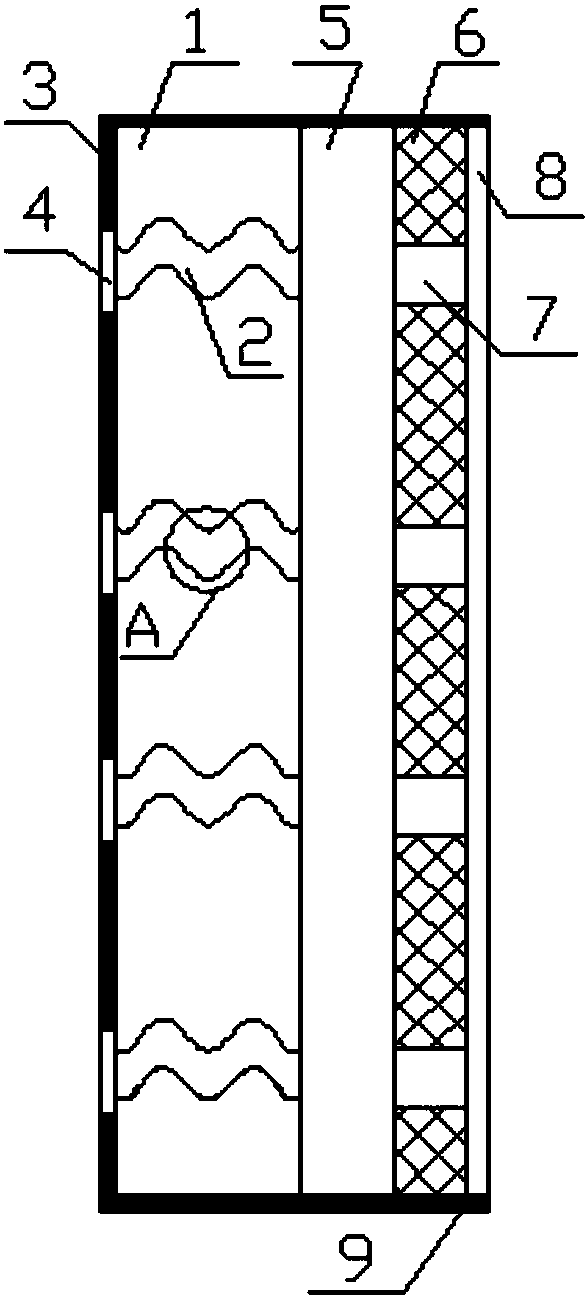

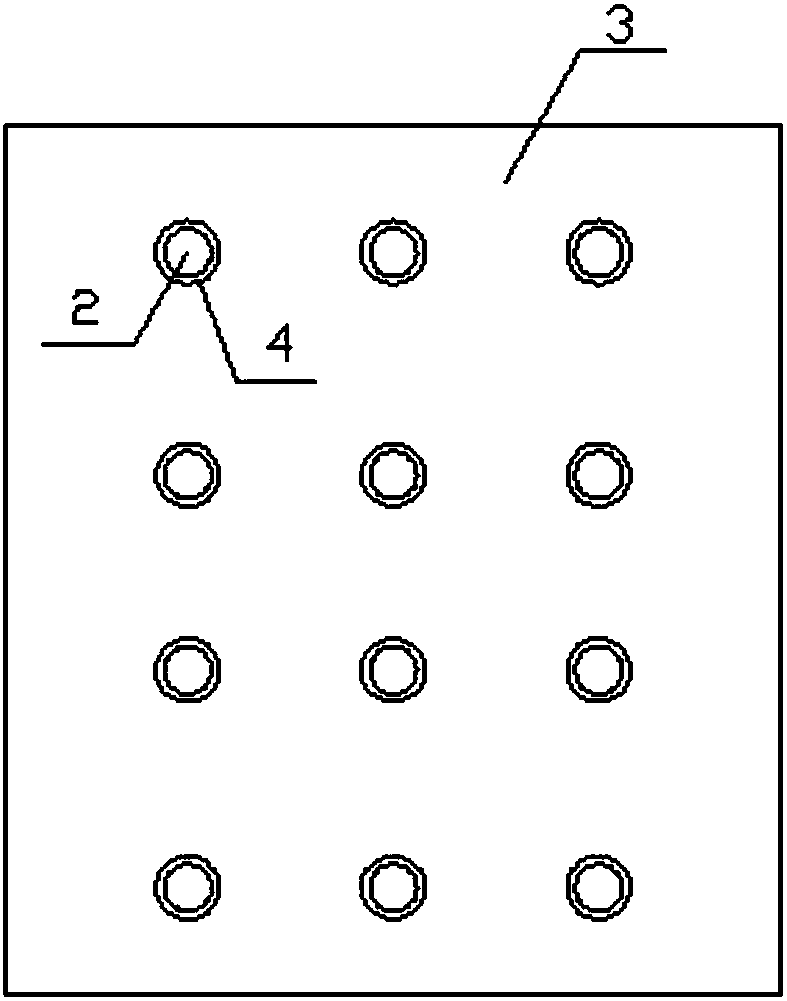

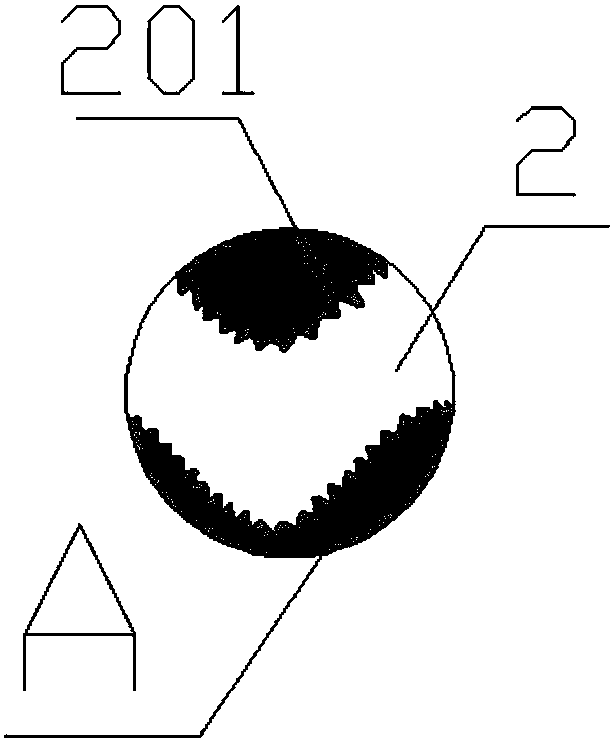

[0024] Such as figure 1 , 2 As shown, an S-shaped perforated panel includes a sound guiding panel 1, a sound absorbing panel 6, a sound insulating panel 8 and a side panel 9, and the surroundings of the sound guiding panel 1, the sound absorbing panel 6 and the sound insulating panel 8 are connected to the side panel 9 A sound-absorbing cavity 5 is provided between the inside of the sound-guiding plate 1 and the outside of the sound-absorbing plate 6, and the inside of the sound-absorbing plate 6 is connected to the sound-insulating plate 8; the inside of the sound-guiding plate 1 is uniformly provided with S-shaped perforations 2, The inside of the sound-absorbing board 6 is uniformly provided with sound-absorbing holes 7; the sound-guiding plate 1, the sound-absorbing cavity 5, the sound-absorbing board 6 and the sound-insulating board 8 are sequentially connected from outside to inside to form an S-shaped perforated board.

[0025] Specifically, the diameters of the S-shap...

Embodiment 2

[0041] Such as Figure 4 As shown, an S-shaped perforated panel includes a sound guiding panel 1, a sound absorbing panel 6, a sound insulating panel 8 and a side panel 9, the sound guiding panel 1 and the sound insulating panel 8 are connected through the side panel 9, and the sound guiding panel 1 A sound-absorbing cavity 5 is formed between the inner side and the outer side of the sound-absorbing panel 6 and the side plate 9, and the inner side of the sound-absorbing panel 6 is connected to the sound-insulating panel 8; the inside of the sound-guiding panel 1 is uniformly provided with S-shaped perforations 2, and the sound-absorbing panel The inside of 6 is uniformly provided with sound-absorbing holes 7; the sound-guiding plate 1, sound-absorbing cavity 5, sound-absorbing plate 6 and sound-insulating plate 8 are sequentially connected from outside to inside to form an S-shaped perforated plate.

[0042] Specifically, the sound-absorbing hole 7 is a trapezoidal hole. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com