Equipment lubricating oil monitoring method and device and system

A lubricating oil and equipment technology, applied in the field of equipment lubricating oil monitoring, can solve the problems of equipment damage, failure to provide lubrication protection, waste, etc., and achieve the effect of avoiding equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

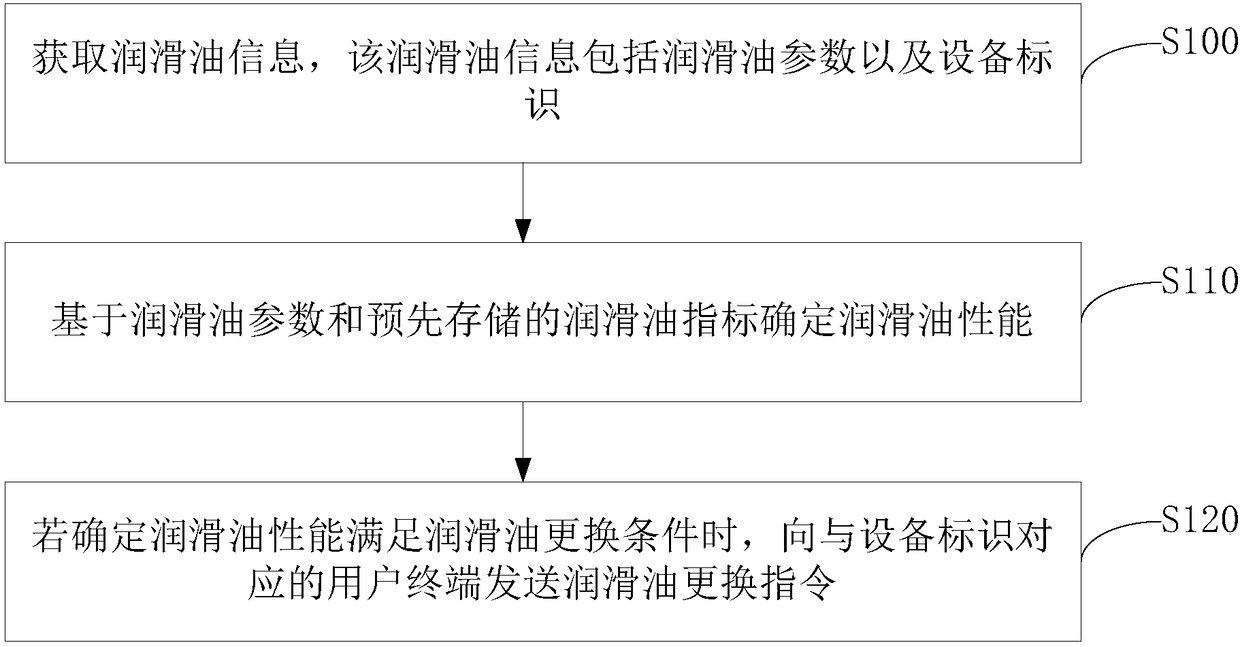

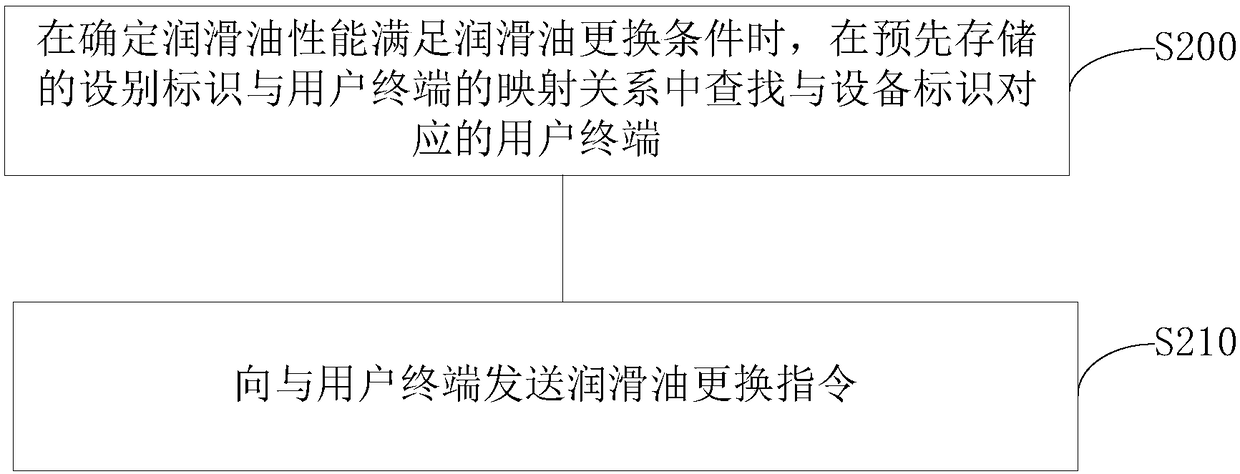

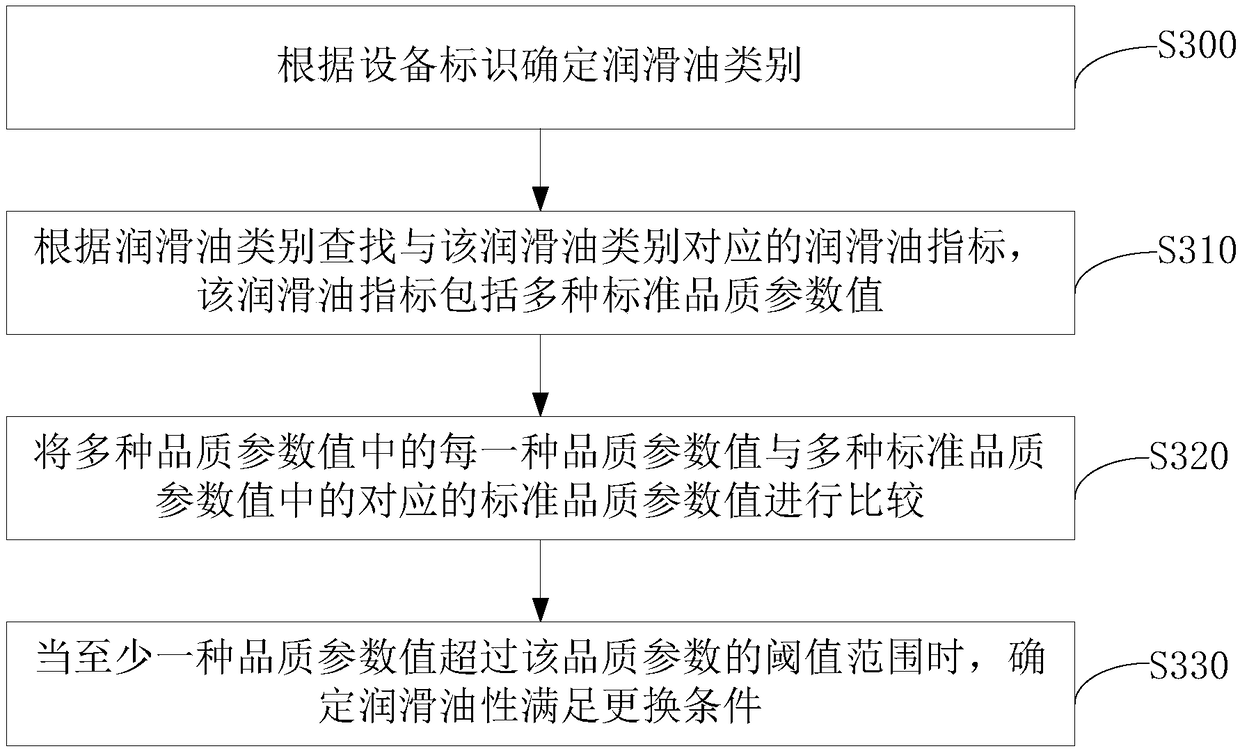

[0050]Embodiment 1 of the present application provides a method for monitoring equipment lubricating oil, such as figure 1 Shown is a schematic flow chart of the method, and the specific steps are as follows:

[0051] S100. Obtain lubricating oil information, where the lubricating oil information includes lubricating oil parameters and equipment identification.

[0052] The lubricating oil information is acquired by the data acquisition terminal or the background server, and step S110 includes:

[0053] When the lubricating oil information is acquired by the data acquisition terminal, the data acquisition terminal collects the lubricating oil information according to the set time interval.

[0054] When the lubricating oil information is acquired by the background server, the background server receives the lubricating oil information uploaded by the data collection terminal according to the set time interval.

[0055] The data acquisition terminal includes multiple data acqu...

Embodiment 2

[0081] Embodiment 2 of the present application provides an equipment lubricating oil monitoring device, such as Figure 5 As shown, it includes: an acquisition module 501 , a determination module 502 and a sending module 503 .

[0082] The acquiring module 501 is configured to acquire lubricating oil information, where the lubricating oil information includes lubricating oil parameters and equipment identification.

[0083] A determining module 502, configured to determine lubricant performance based on the lubricant parameters and pre-stored lubricant indicators;

[0084] The sending module 503 is configured to send a lubricating oil replacement instruction to the user terminal corresponding to the device identifier when the determining module determines that the performance of the lubricating oil meets the lubricating oil replacement condition.

[0085] Preferably, the equipment lubricating oil monitoring device also includes a search module;

[0086] The search module is ...

Embodiment 3

[0101] Embodiment 3 of the present application provides an equipment lubricating oil monitoring system, such as Figure 6 What is shown includes: a data collection terminal 601, a background server 602 and a user terminal 603 respectively arranged on different devices, and the background server 602 is connected to the data collection terminal 601 and the user terminal 603 respectively.

[0102] The data collection terminal 601 is used to collect lubricating oil parameters of the associated equipment, and send the lubricating oil parameters and the equipment identification of the associated equipment to the background server 602 .

[0103] The background server 602 is used to determine the lubricating oil performance based on the lubricating oil parameters and pre-stored lubricating oil index values when the lubricating oil parameters and equipment identification are obtained. If the determined lubricating oil performance meets the lubricating oil replacement conditions, send ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com