Plastic dicing device with good radiation

A plastic and granulation technology, applied in the field of plastic products production, can solve problems such as shortened service life, heat not dissipated in time, equipment failure, etc., and achieve the effects of avoiding equipment failure, ensuring cleanliness, and reducing burst rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

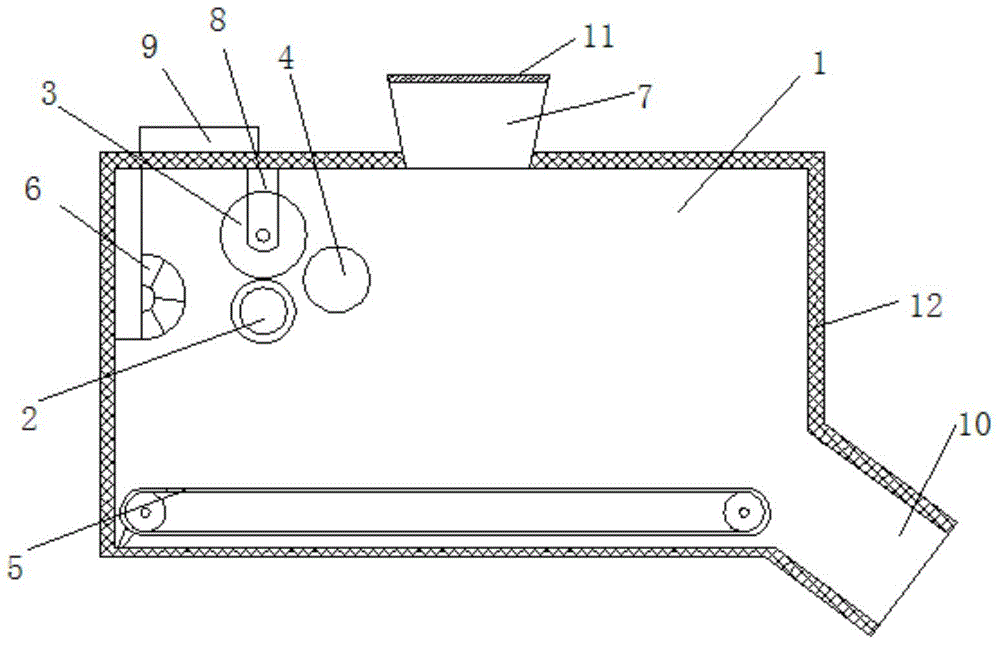

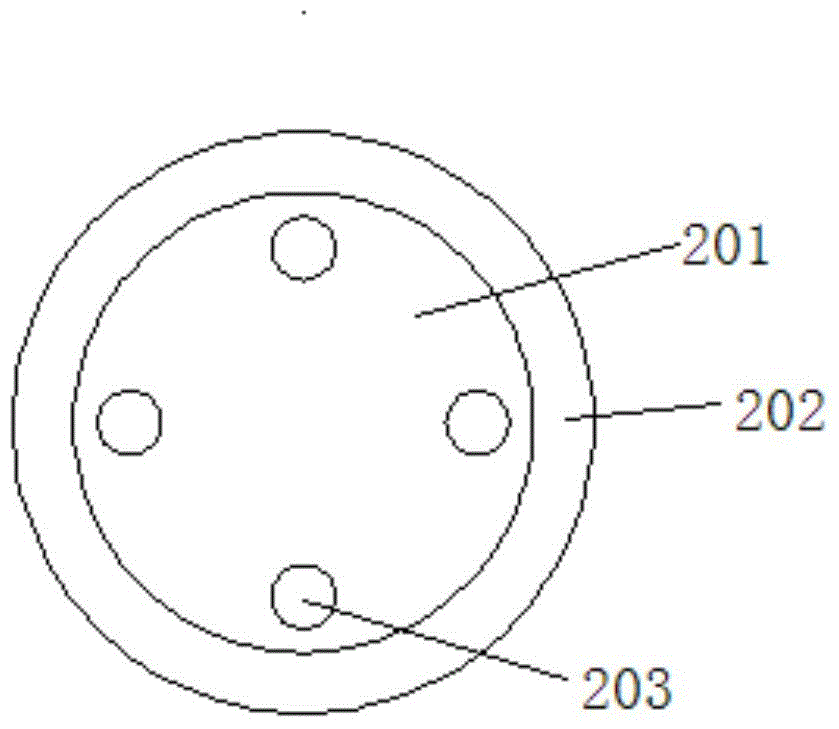

[0015] See attached figure 1 And attached figure 2 , a plastic granulation device with good heat dissipation, including a cutting chamber 1, a rubber roller 2, a traction roller 3, a cutter 4, a conveyor belt 5, a blower 6 and an exhaust hood 7, and the rubber roller 2 and the traction roller 3 pass through The bracket 8 is arranged at the upper position in the cutting chamber 1, the rubber roller 2 includes a steel core 201 and a rubber layer 202 coated on the outer surface of the steel core 201, and the two ends of the steel core 201 are provided with ventilation holes penetrating the steel core 203, the ventilation holes 203 are evenly arranged in a circular shape on the end face of the steel core, the number of ventilation holes is 4, the material of the rubber layer 202 is polyurethane, and the conveyor belt 5 is arranged at the bottom positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com