Automatic control type heater

A heater and controller technology, applied in the control of combustion, lighting and heating equipment, combustion methods, etc., can solve the problems of increasing production costs, affecting production efficiency, heat waste, etc., saving production costs, saving manpower and material resources, and improving The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

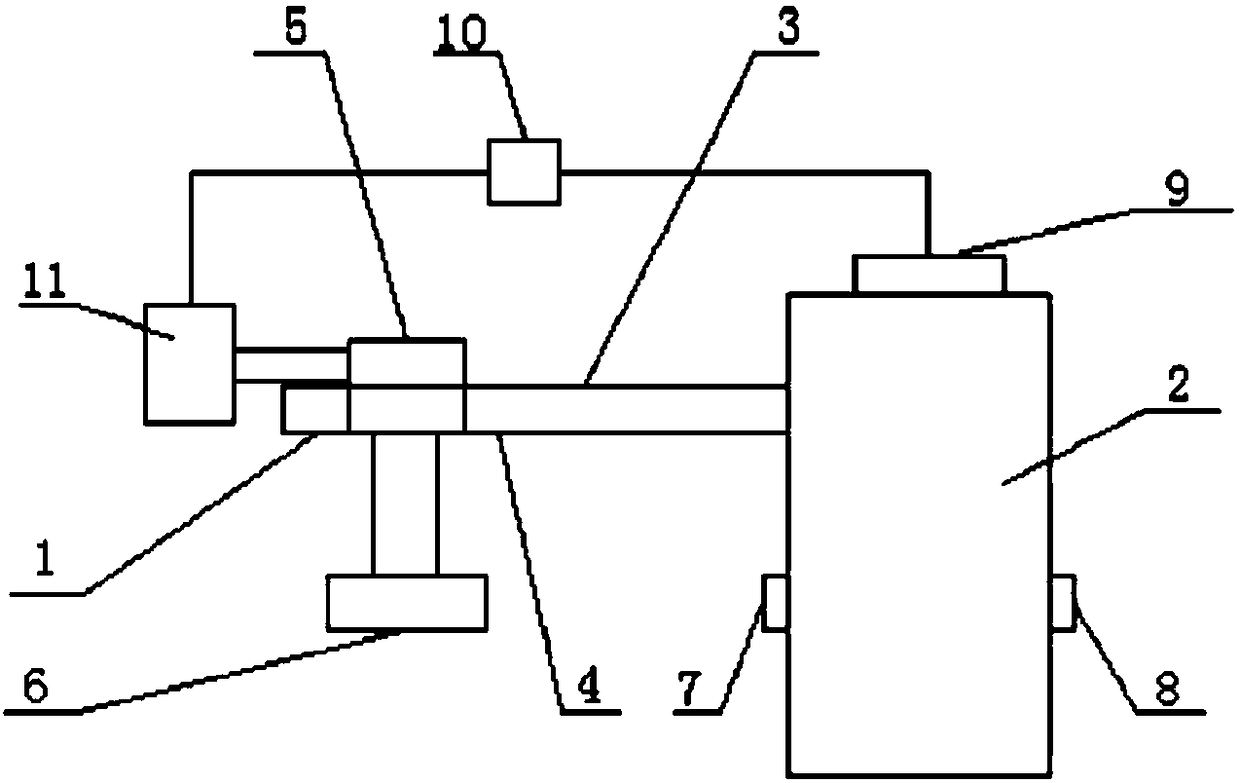

[0011] Such as figure 1 As shown, an automatic control type heater includes a delivery device 1 and a combustion device 2, the delivery device 1 is connected to the combustion device 2, the delivery device 1 includes a sliding device 3, the sliding device 3 includes a slide rail 4, and the slide rail 4 is slidably connected with a slider 5, and the slider 5 is driven by a cylinder 11, and the bottom of the slider 5 is connected to the loading device 6; the combustion device 2 is provided with a fuel inlet 7 and an air inlet 8, and the top of the combustion device 2 is provided with There is a detection device 9, and the detection device 9 is connected to a controller, the controller is a PLC10, and the PLC10 is connected to the cylinder 11 of the conveying device 1.

[0012] The working process of this example: the fuel is moved from the loading device 6 on the slide rail 4 through the slider 5 to the fuel inlet 7 and enters the combustion device 2, the fuel burns in the combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com