Cable winding device

A twisted wire and cable technology, which is applied in the field of cable twisting devices, can solve the problems such as the artificial twisting of wires is not tight, and achieve the effects of avoiding tight twisting of wires, reducing jumping wires and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

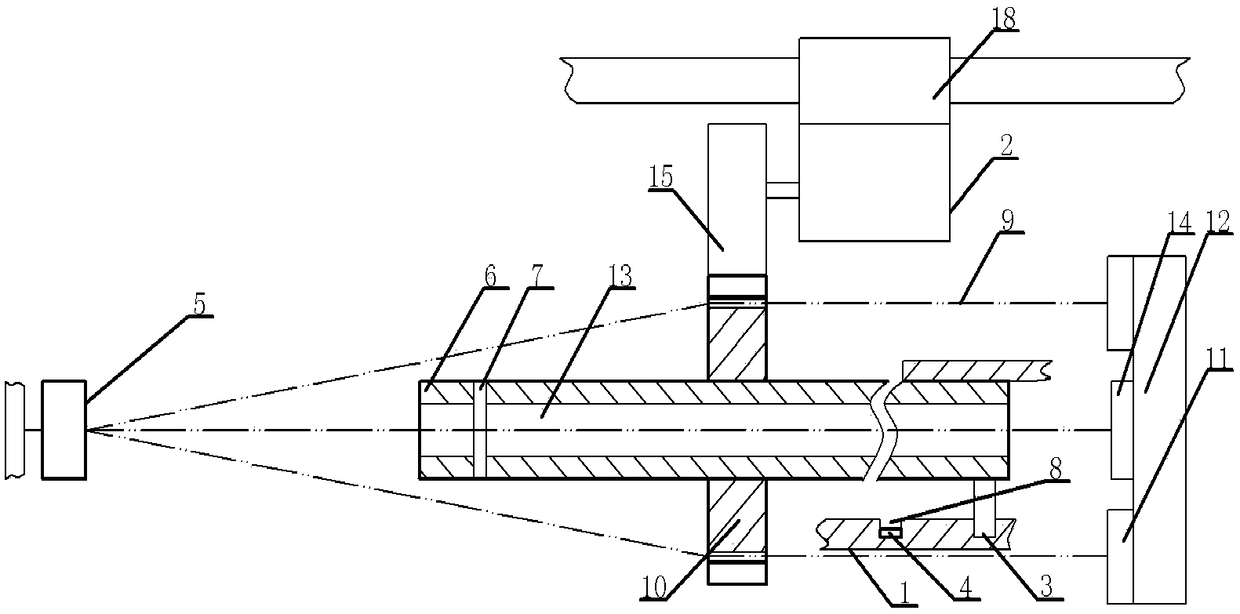

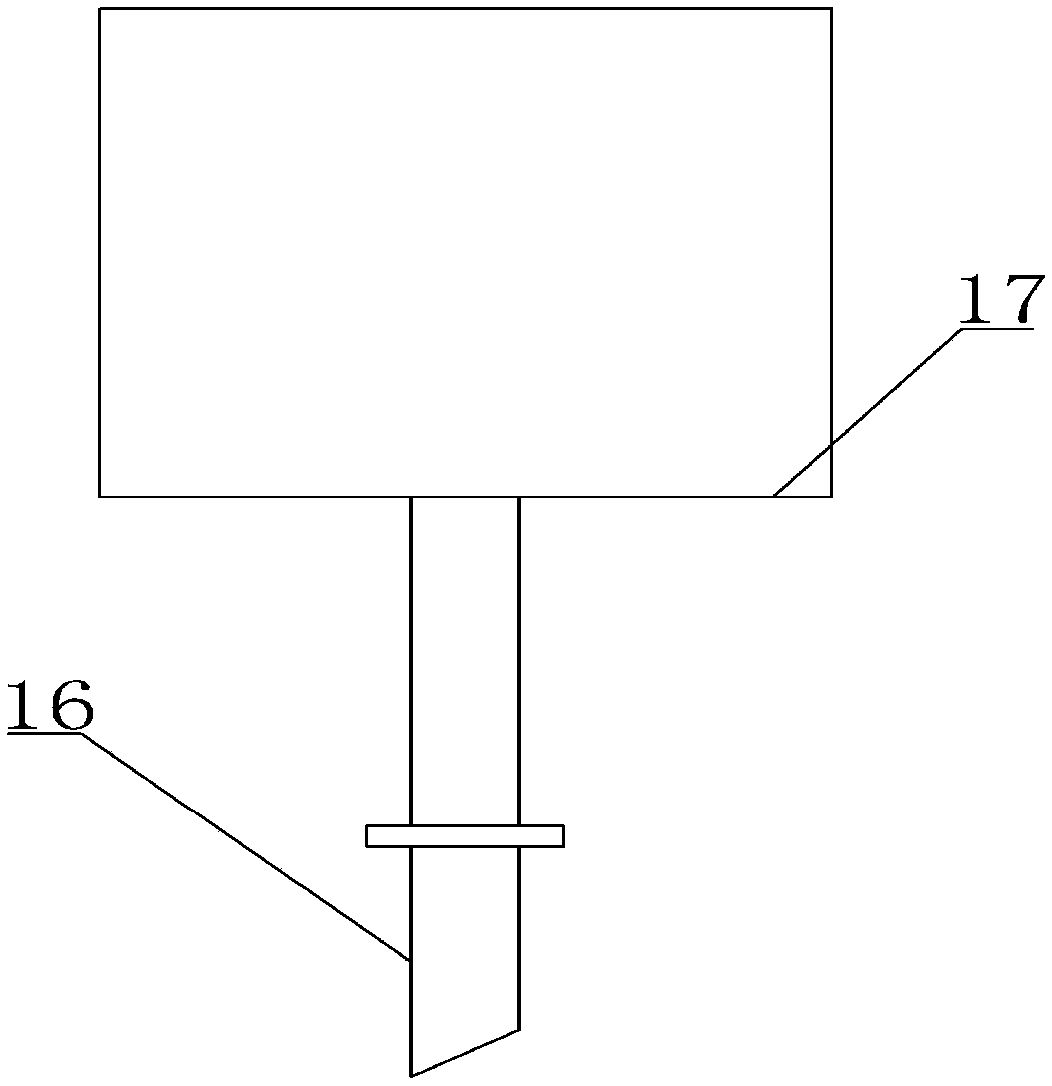

[0018] as attached figure 1 And attached figure 2 As shown, a cable stranding device includes a frame 1, a first motor and a second motor 2, a nailing block 5 is slidingly connected to one side of the frame 1, and a wire fixing hole is provided on the nailing block 5, and the frame On the 1, the side opposite to the nailing block 5 is rotatably connected with a turntable 12, and the turntable 12 is fixedly connected with the output shaft of the first motor, and the first motor is fixedly installed on the frame by fastening bolts. A central rod 6 that is slidingly connected to the frame 1 is arranged between the nailing block 5 and the rotating disk 12. The central rod 6 is placed horizontally, and the central rod 6 is fixedly connected with the nailing block 5 through a connecting shaft. Center rod 6 is provided with through hole near one end of nail line block 5, and the outside of center rod 6 is provided with sliding groove, and the first gear 10 is connected with rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com