Patents

Literature

80results about How to "Same force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

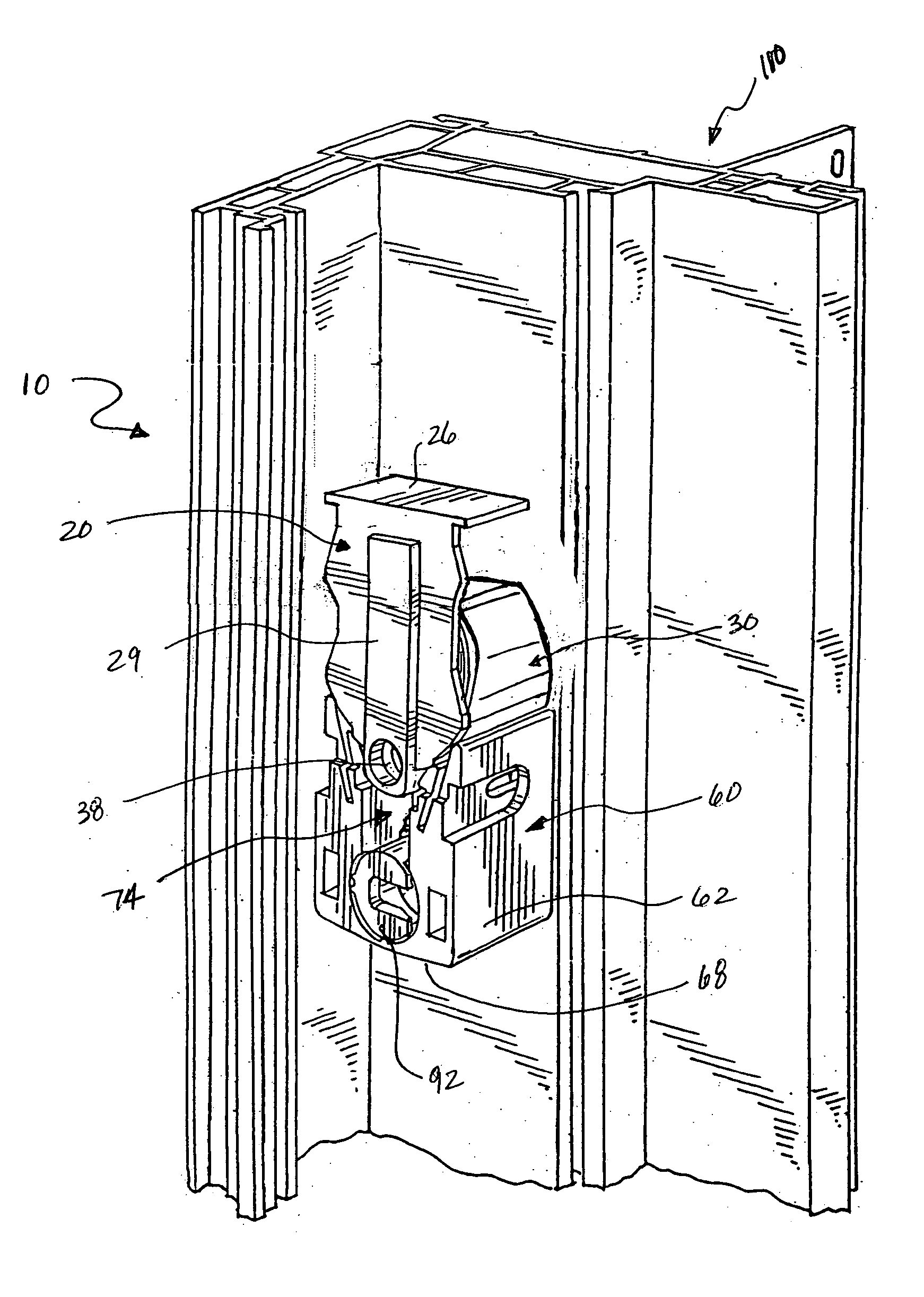

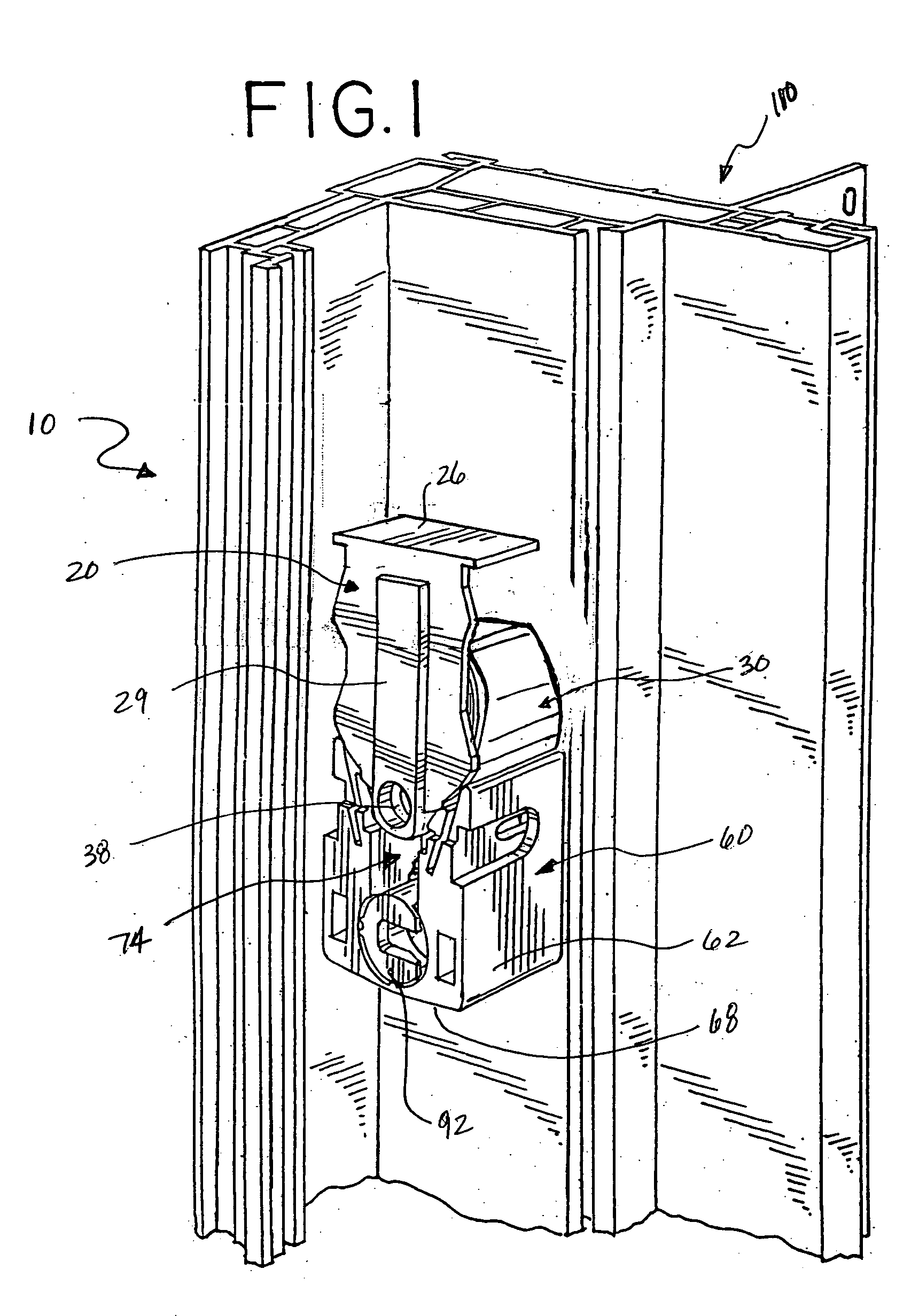

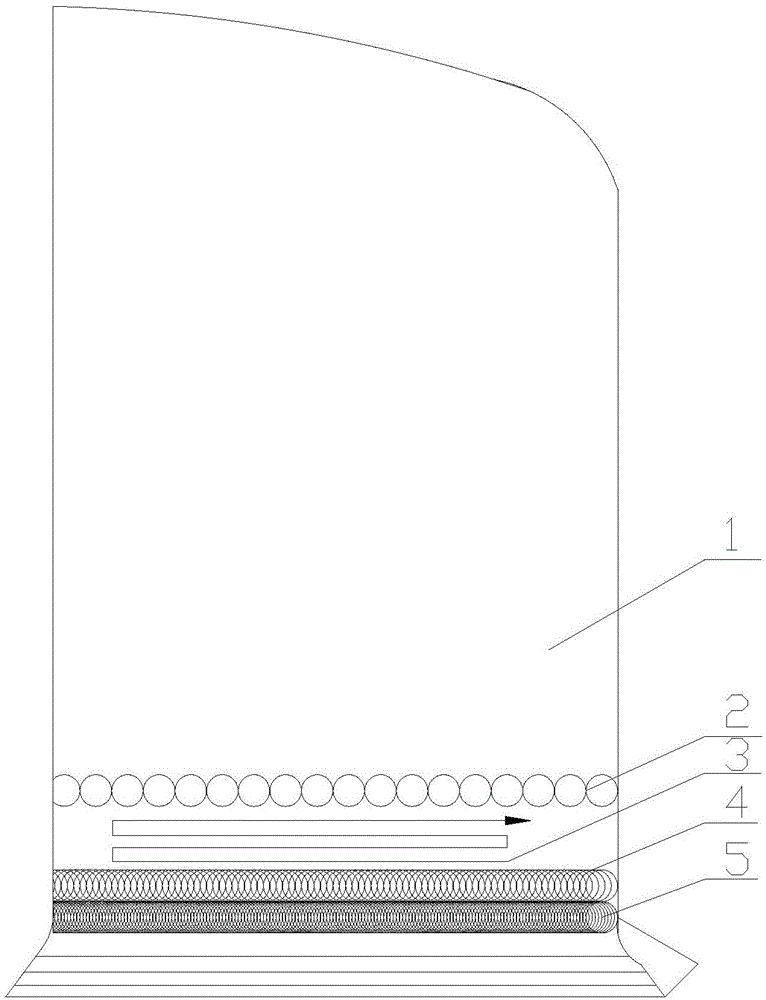

Spring balance assembly

InactiveUS20050198775A1Reduced dimensionExpand exportsBuilding braking devicesWing openersSash windowEngineering

The present invention provides a balance assembly for use with a sash window assembly slidable within a master frame. The balance assembly generally includes a plate, a spring assembly, and a brake shoe or pivot brake assembly. The plate is removably connected to the master frame. The spring assembly includes a first spring that is inter-wound or nested within a second spring. Each spring has a coiled portion, an intermediate portion, and a free portion. The coiled portions of the springs are rotatably supported by the support member that extends from the plate. The free portions of the springs have a curved configuration and are received by a slot in the brake shoe, which is operably coupled to the sash window. The inter-wound springs exert a balancing force on the sash window during movement of the window.

Owner:NEWELL OPERATING COMPANY

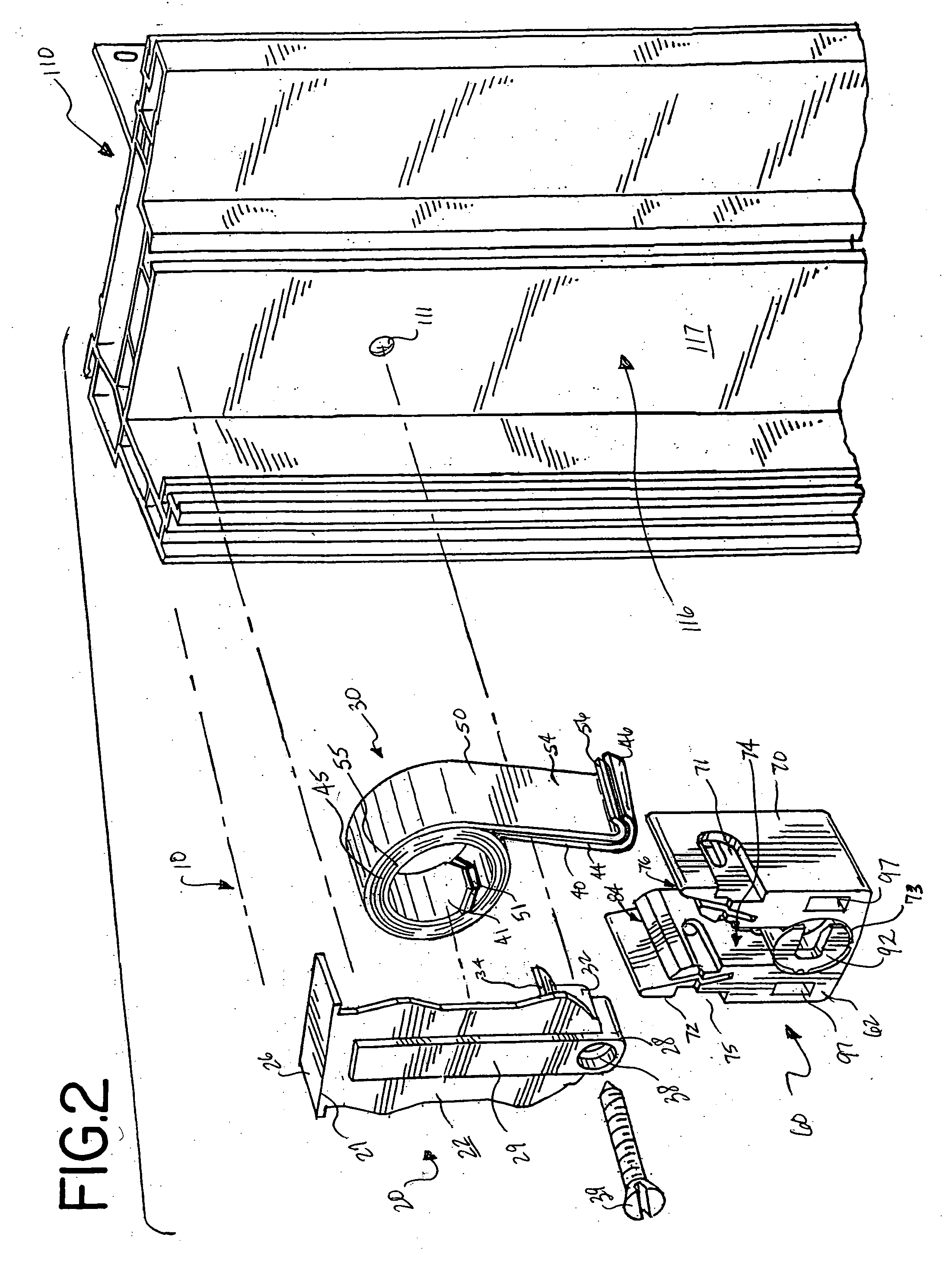

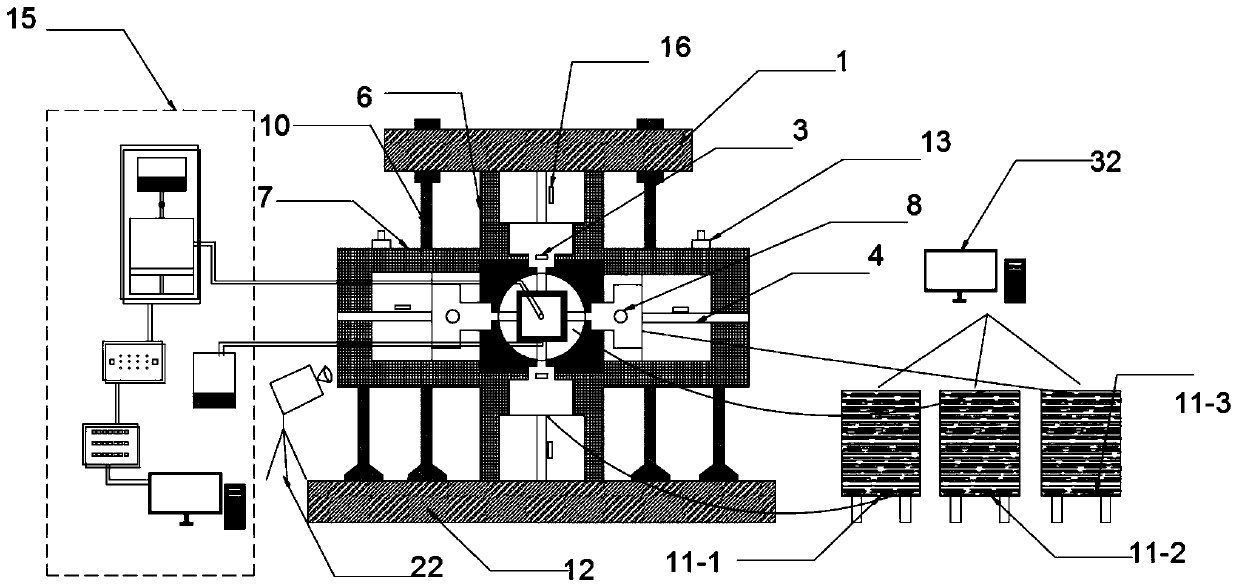

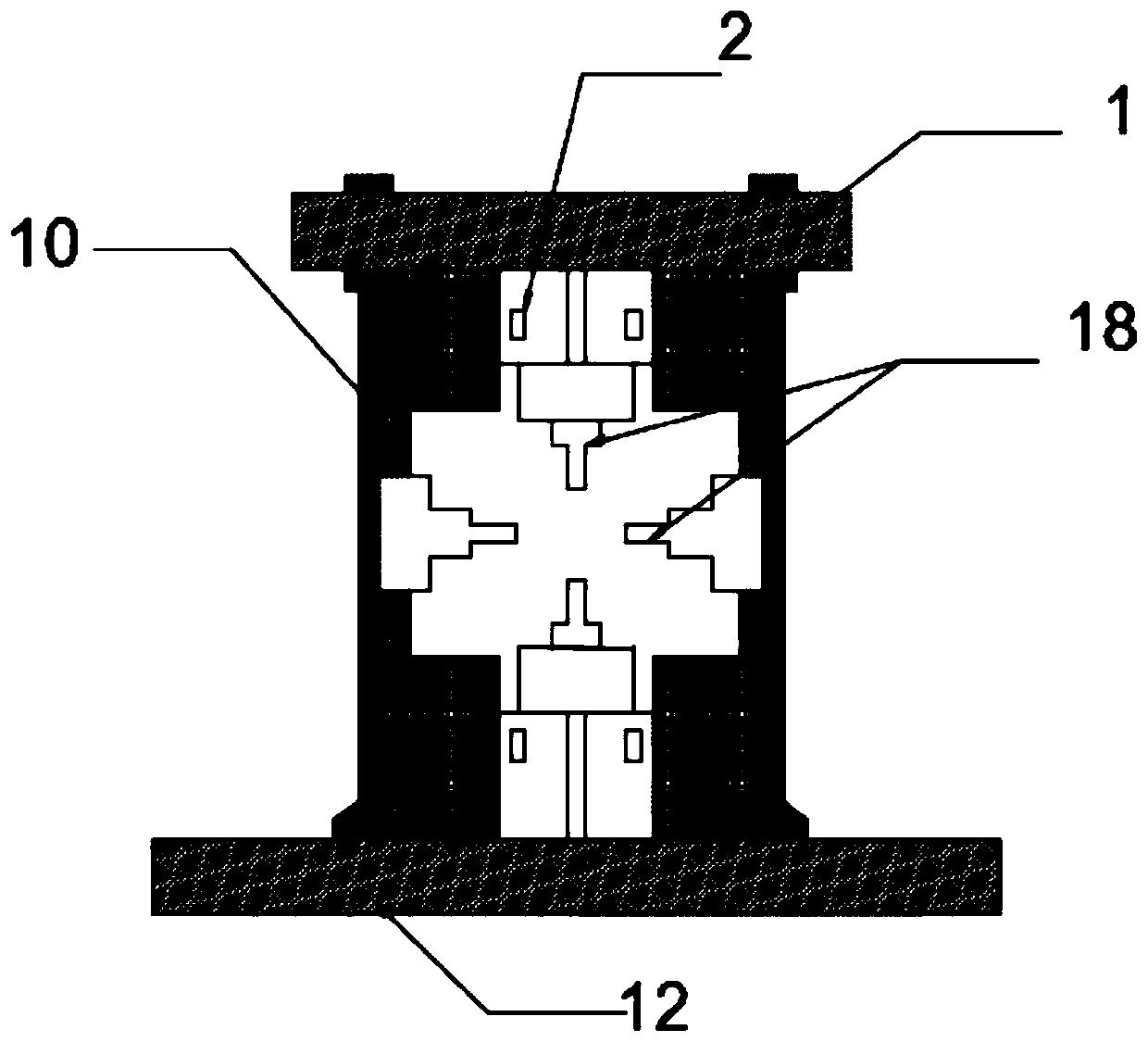

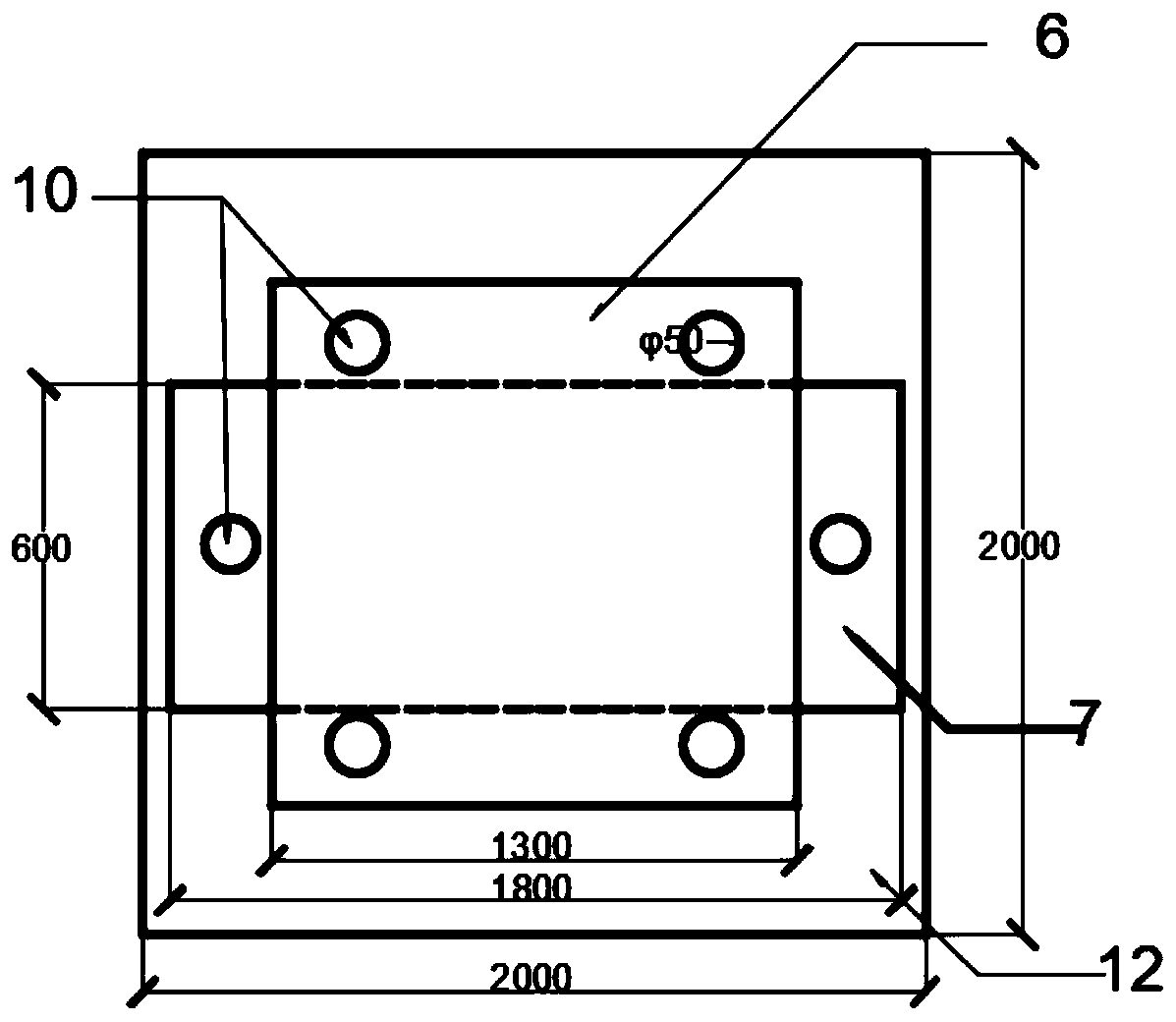

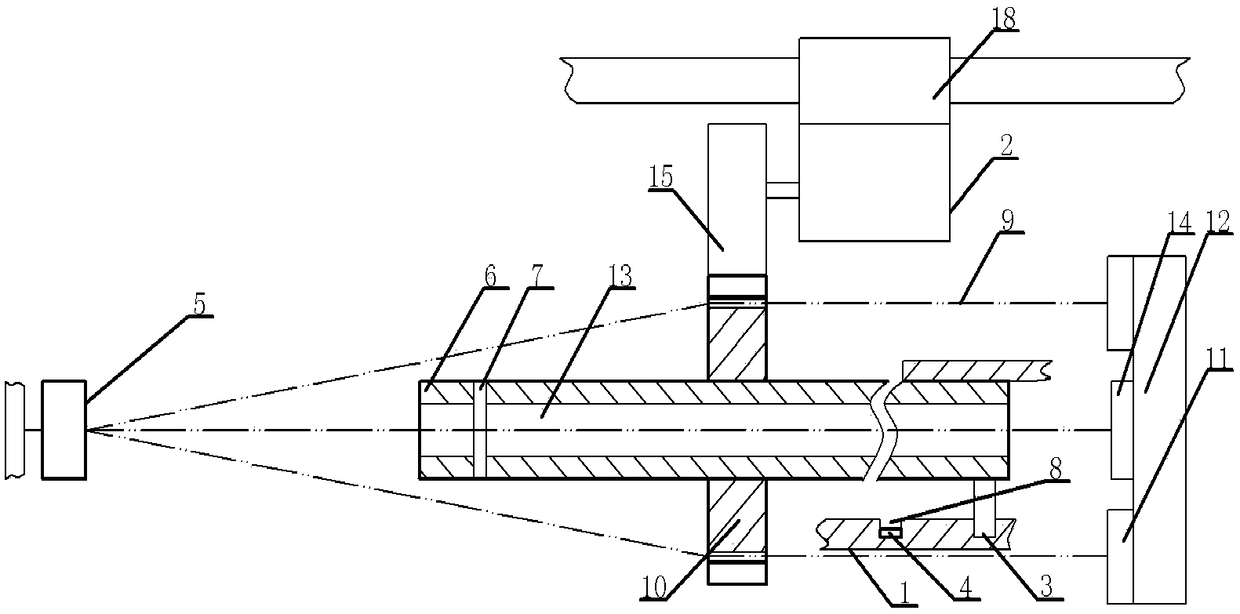

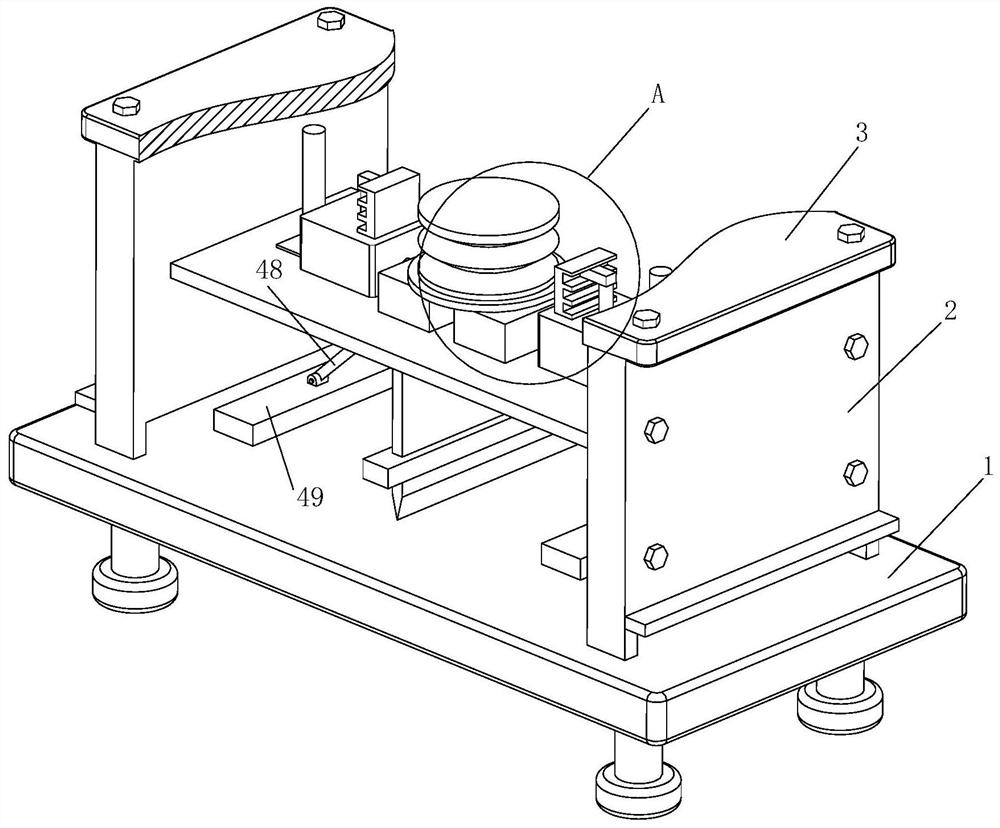

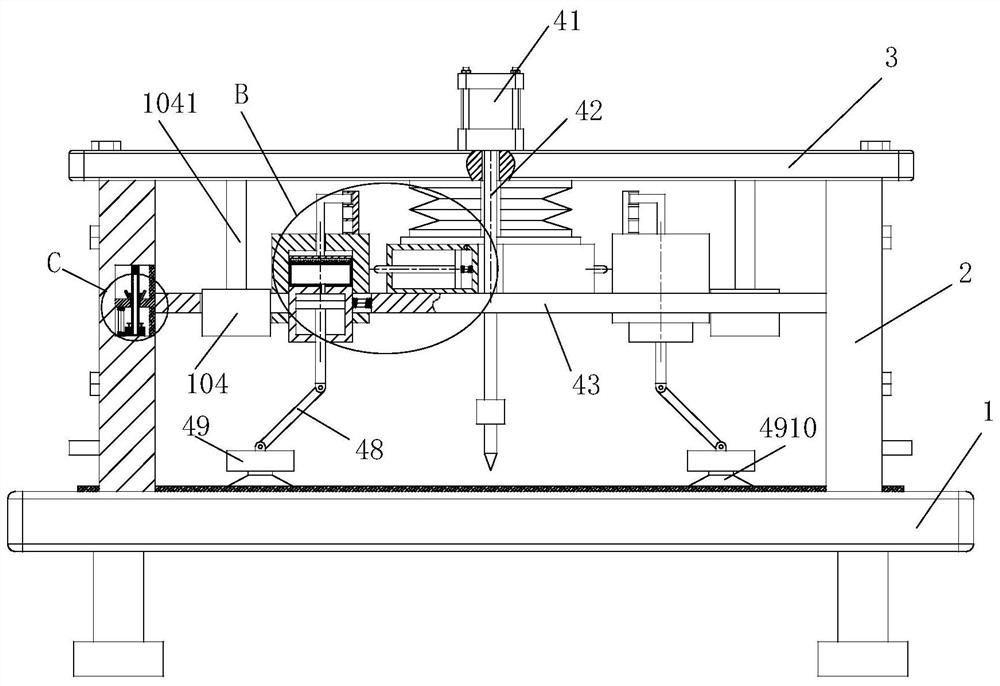

Visual true triaxial hydraulic fracturing test device and method

InactiveCN110987638AMeet testing needsSimple and fast operationMaterial strength using tensile/compressive forcesAxial pressureFracturing fluid

The invention discloses a visual true triaxial hydraulic fracturing test device and a visual true triaxial hydraulic fracturing test method. The visual true triaxial hydraulic fracturing test device comprises a vertical axial pressure loading system, a horizontal stress loading system, a confining pressure loading system and the like, wherein a hydraulic loading system adopts high-transparency oilto perform flexible servo loading on six surfaces of a rock sample, and a hydraulic loading system is mounted on a flexible loading surface to realize hydraulic fracture; in order to ensure the sealing performance of a cylinder body of a pressure chamber, oil leakage prevention elastic rubber sleeves are fixed at the contact parts of the vertical axial pressure loading system, the horizontal stress loading system and the pressure chamber; a water pressure loading system realizes hydraulic fracture through carrying out water injection on the flexible loading surface, and fracturing fluid is collected by means of a rigid water guide base plate; and a high-speed camera is used for collecting the crack propagation process of the sample in the visual pressure chamber. In addition, the visual true triaxial hydraulic fracturing test device can further complete a hydraulic fracturing test of a cylindrical sample under the condition of false triaxial loading, and meet the test requirements ofrock samples with different shapes.

Owner:SHANDONG UNIV +1

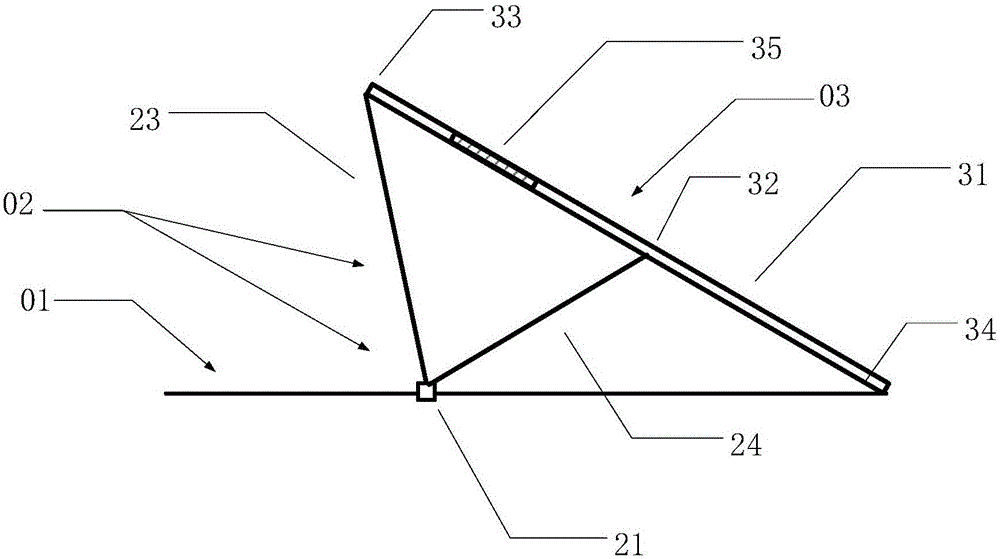

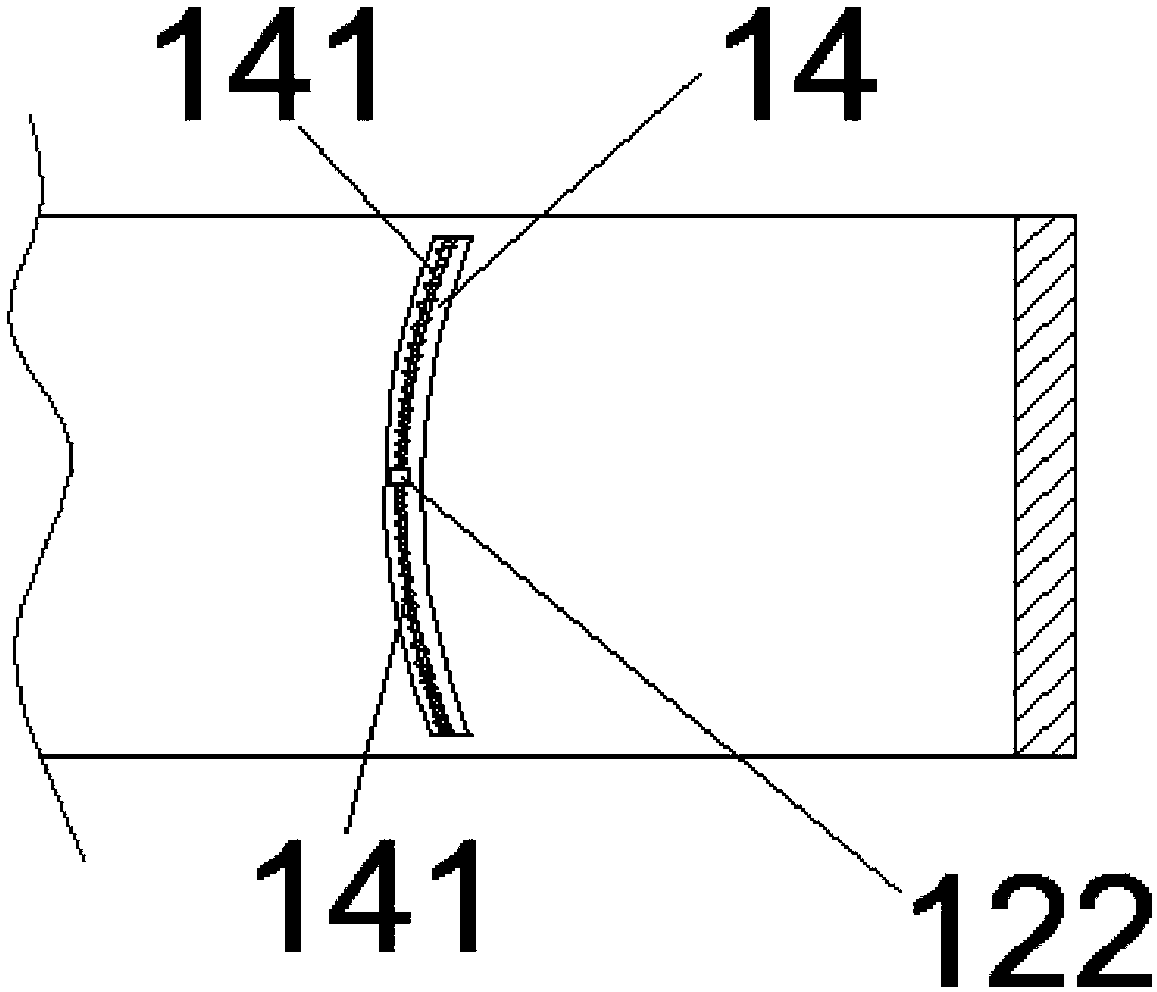

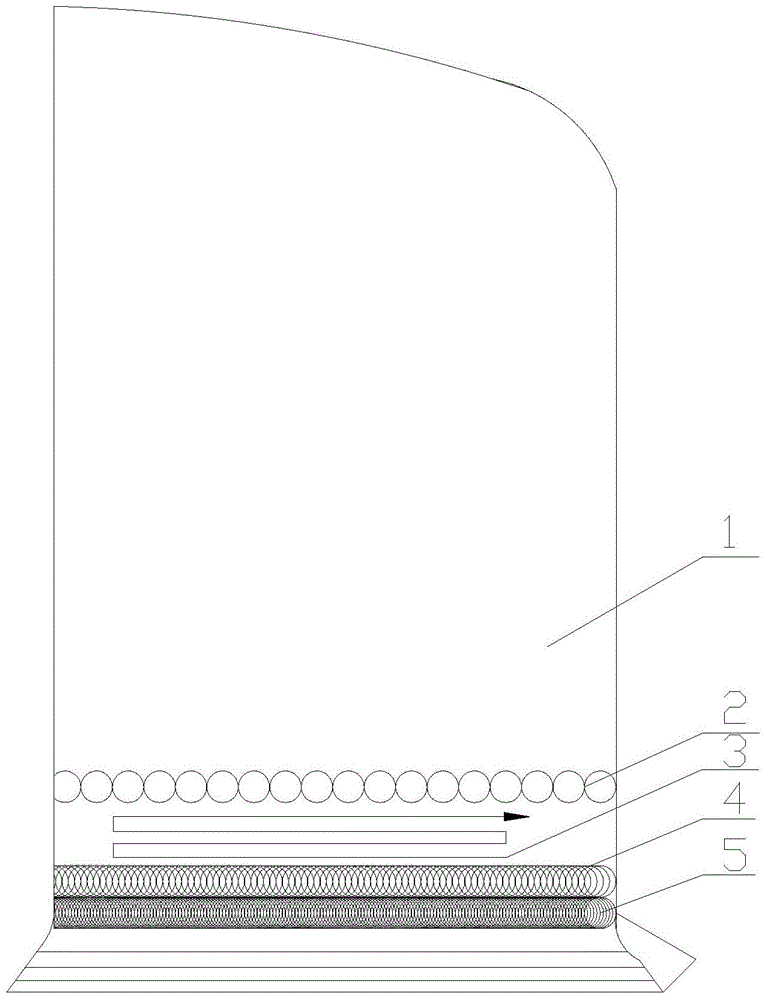

Method for prolonging service life of turbine blade based on laser double-faced impact technique

ActiveCN104862468AMake up for the shortcomings of insufficient depth of influenceFlat change in distributionBlade accessoriesMachines/enginesPeeningHigh energy

The invention relates to a method for prolonging the service life of a turbine blade based on a laser double-faced impact technique. The method comprises the following steps: firstly carrying out equal-energy laser beam splitting by virtue of a Nd:YAG pulsed laser; then simultaneously impacting the front and rear surfaces by virtue of gradually-changed light spot overlapping rate by taking running water as a restraint layer so as to strength the root of the blade, fixing the turbine blade by virtue of a fixture, and simultaneously impacting the front and rear surfaces of the bottommost layer of the root of the blade by virtue of high-energy large-light-spot pulse laser and 90% of the overlapping rate; when impact strengthening at each height is finished, descending a lifting platform by a height of the light spot diameter, and impacting by virtue of the overlapping rate which is 10% smaller than the former overlapping rate; and finishing the laser impact strengthening of the root of the blade until the overlapping rate is 0. According to the method, the disadvantage of insufficient mechanical shot blasting influence depth is made up, and by impacting the root of the blade by virtue of the gradually-changed overlapping rate, the distribution change of a residual stress field becomes flat; by virtue of laser double-faced impact manner, the deformation and damage of the blade caused by laser single-faced impact are avoided, and meanwhile, the front and rear surfaces of the blade are equally stressed.

Owner:WENZHOU UNIVERSITY

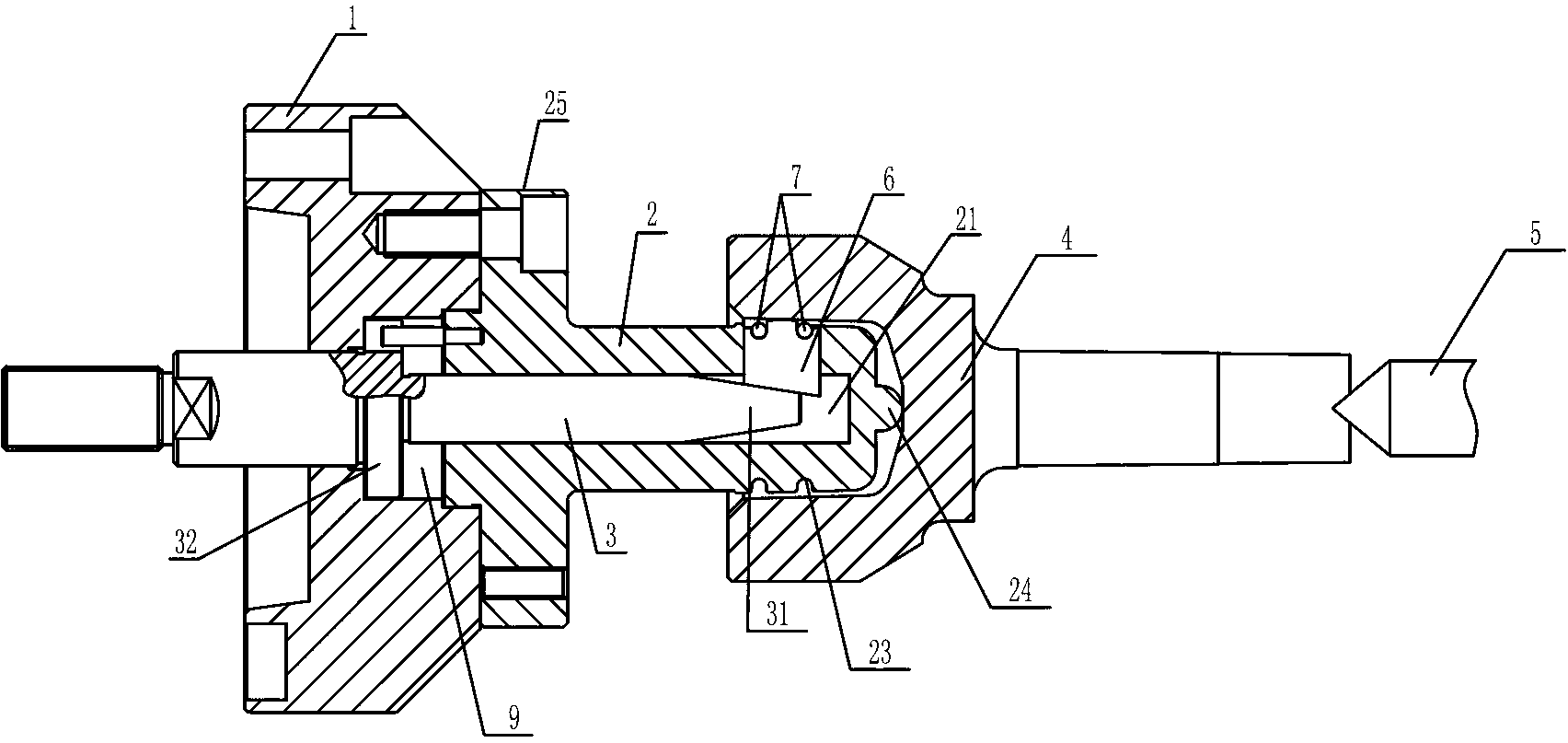

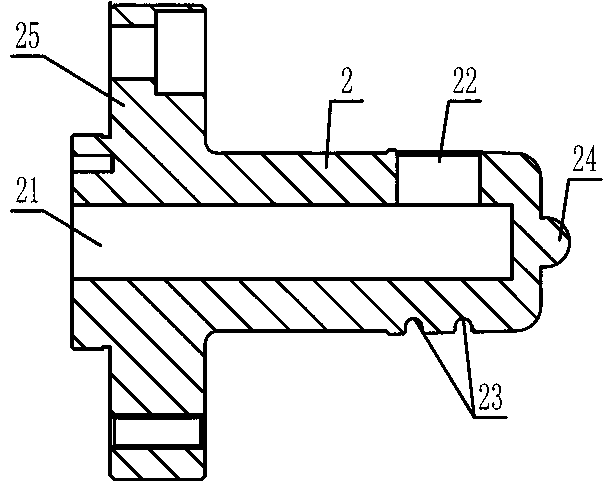

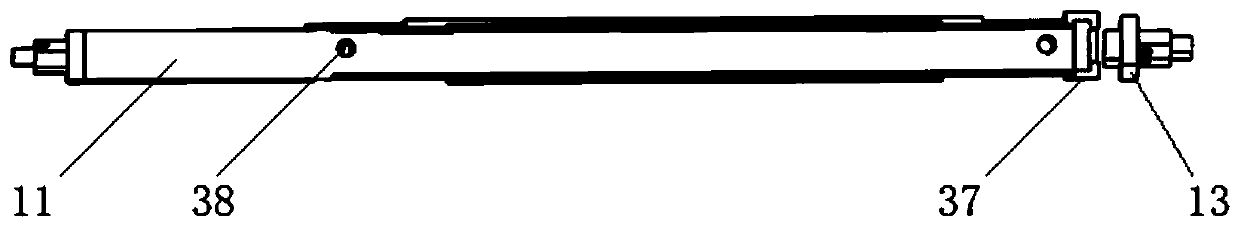

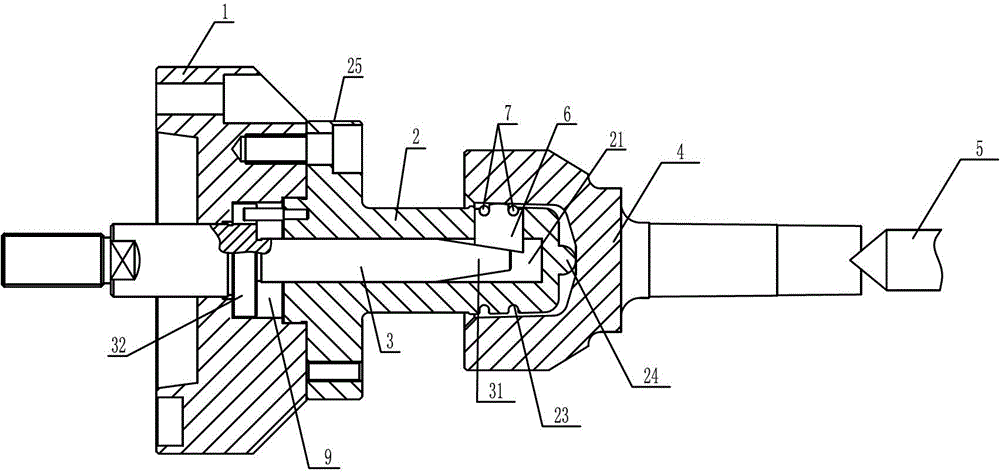

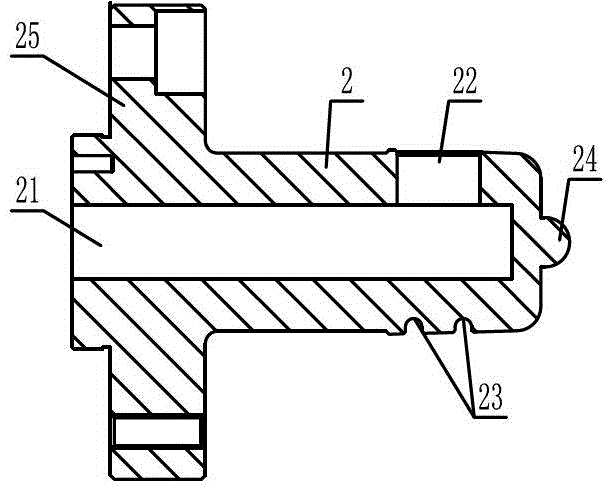

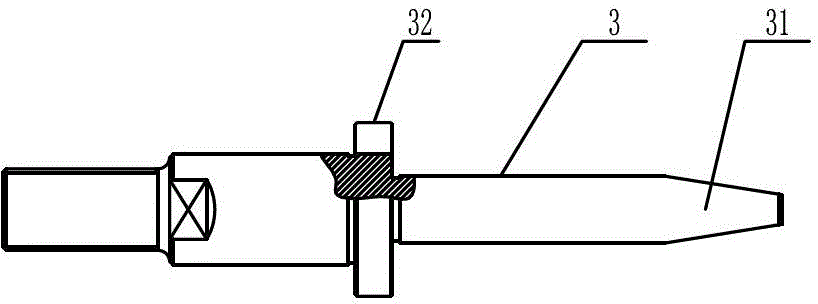

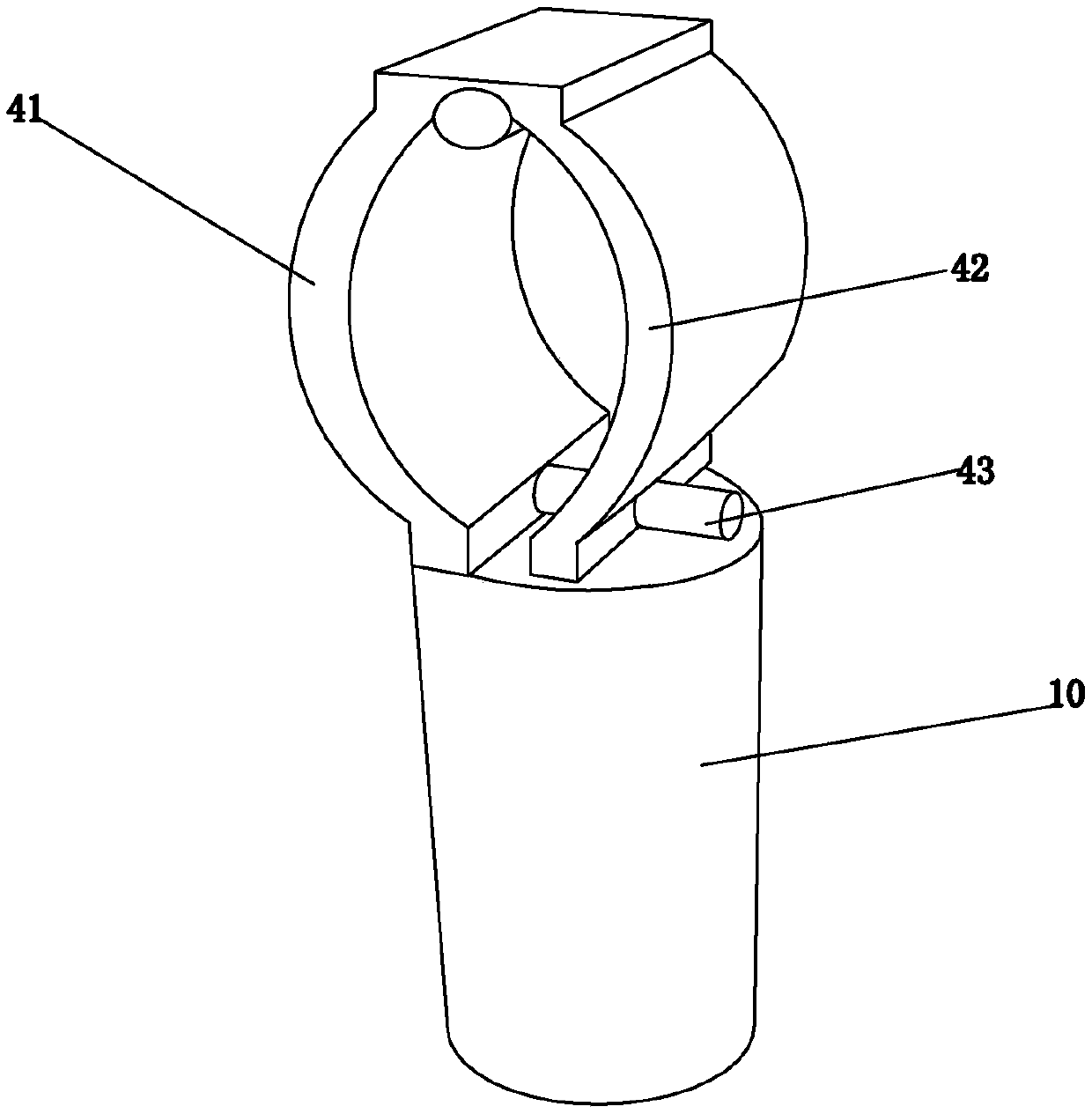

Inner-supporting clamp of constant-velocity universal joint bell housing

The invention provides an inner-supporting clamp of a constant-velocity universal joint bell housing, which is mainly applied to the machining field of the constant-velocity universal joint bell housing. The inner-supporting clamp comprises a clamp body, wherein a top block is arranged on the side part at the front end of the clamp body; and an ejecting structure for ejecting the top block is arranged on the clamp body. The inner-supporting clamp of the constant-velocity universal joint bell housing can be used for clamping the constant-velocity universal joint bell housing by one step, and simultaneously completing rough-finish turning machining of the outer diameter and the end surface of the bell housing, so that secondary clamping error risks are removed and the time consumption for disassembling the clamped workpiece is reduced. Besides, the inner-supporting clamp of the constant-velocity universal joint bell housing has the advantages of being high in machining product precision, small in labor intensity and high in production efficiency.

Owner:ZHEJIANG ODM TRANSMISSION TECH

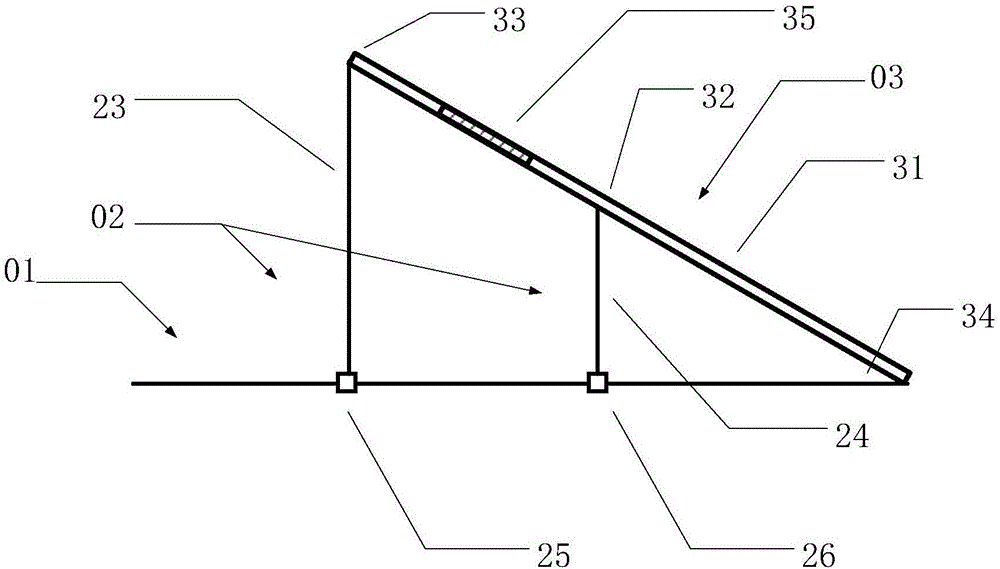

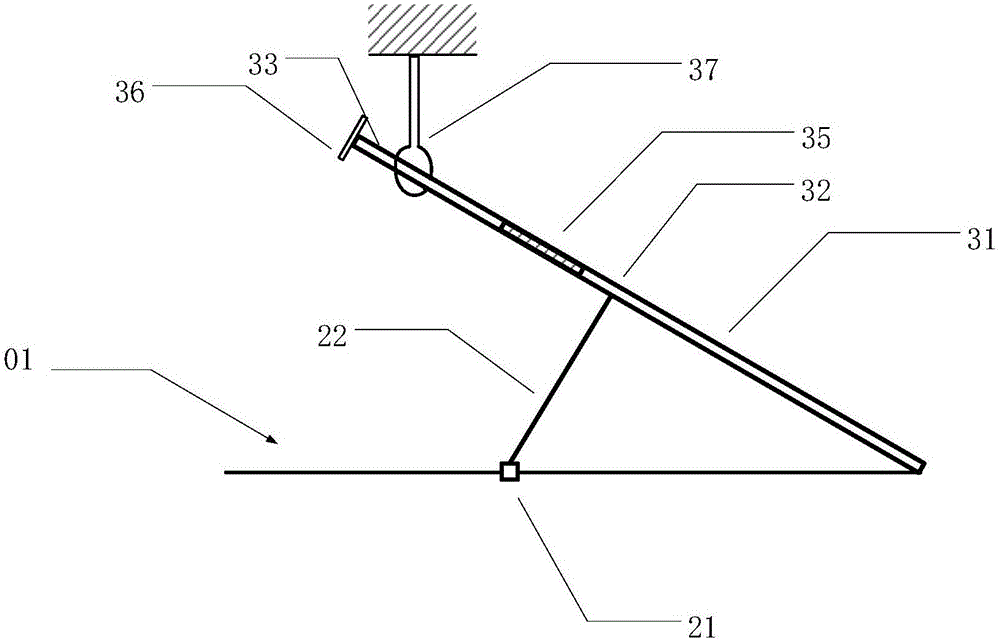

Tidal current energy and vortex-induced vibration energy comprehensive power generation device

ActiveCN106870269AImprove extraction efficiencyChange vibration frequencyPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesVibration amplitudeWater turbine

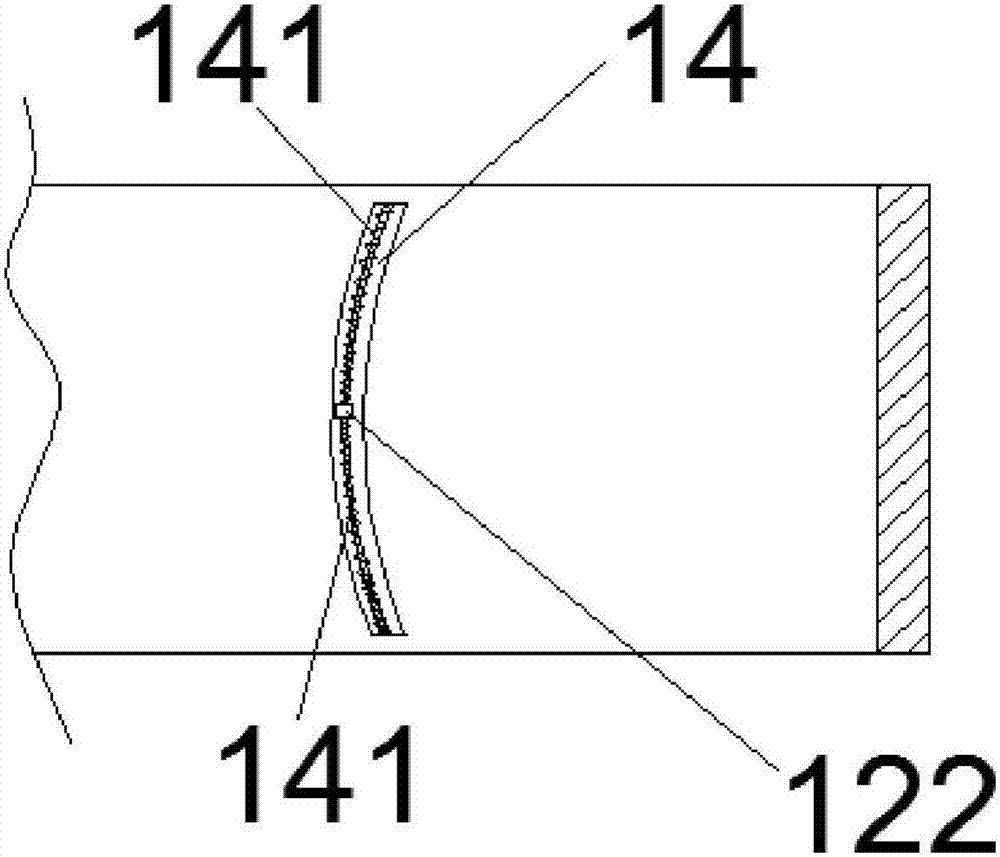

The invention provides a tidal current energy and vortex-induced vibration energy comprehensive power generation device. The tidal current energy and vortex-induced vibration energy comprehensive power generation device comprises a tidal current energy water turbine and a vortex-induced vibration energy capturing device. A power generator, a power distribution box and a rectifying and voltage-stabilizing device which are sequentially connected with an impeller through wires are arranged in a power generator cabin of the tidal current energy water turbine. The vortex-induced vibration energy capturing device comprises a shell, a vibrator sliding along a guide rail, and a piezoelectric plate, wherein the shell is mounted on the rear side of a single pile foundation, the two end edges of the vibrator are arranged on the top surface and the bottom surface of the shell, and the two ends of the piezoelectric plate are connected with the vibrator and the rear end face of the shell correspondingly; and a conductive copper sheet is arranged at the end, connected with the rear end face of the shell, of the piezoelectric plate and sequentially connected with the rectifying and voltage-stabilizing device and the power distribution box located in the power generator cabin through wires. Water flow enters the shell after encountering the single pile foundation of the water turbine, vortexes falling alternately are generated on the two sides of the pile foundation, and vortex resonance is formed when the vortexes pass through the vibrator; and under the wake flow galloping effect, the vibration amplitude of the vibrator is greater than the vibration amplitude caused by resonance of ordinary vortexes, the vibrator drives the piezoelectric plate to swing left and right, and thus mechanical energy is converted into electric energy.

Owner:HOHAI UNIV +1

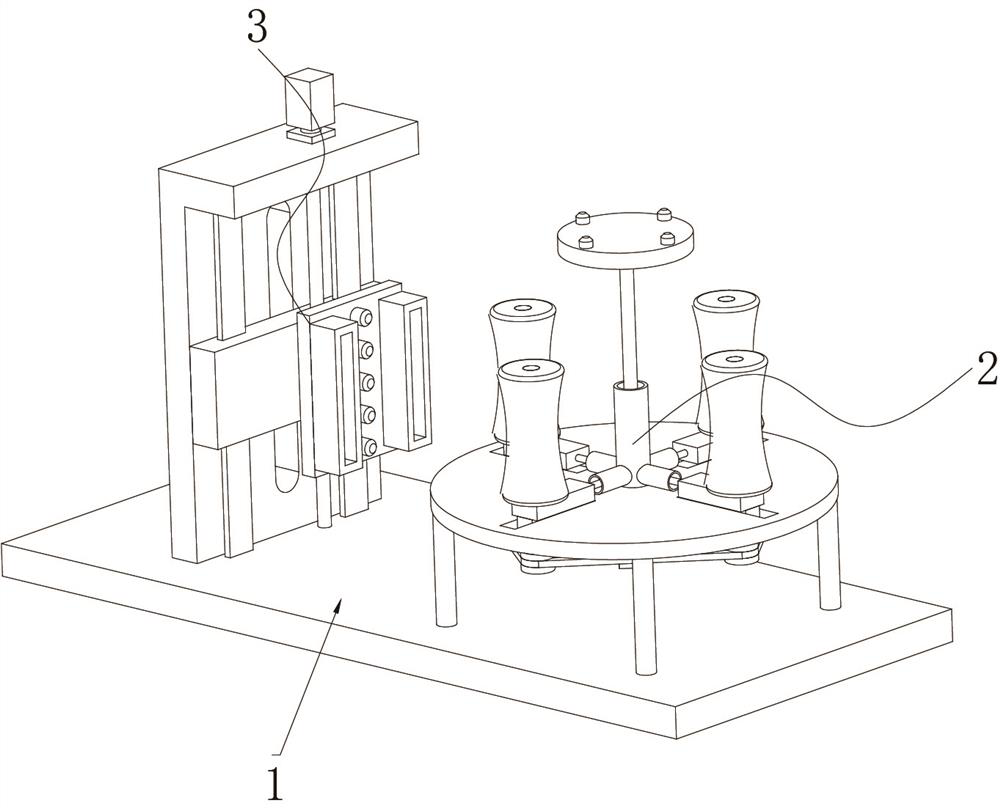

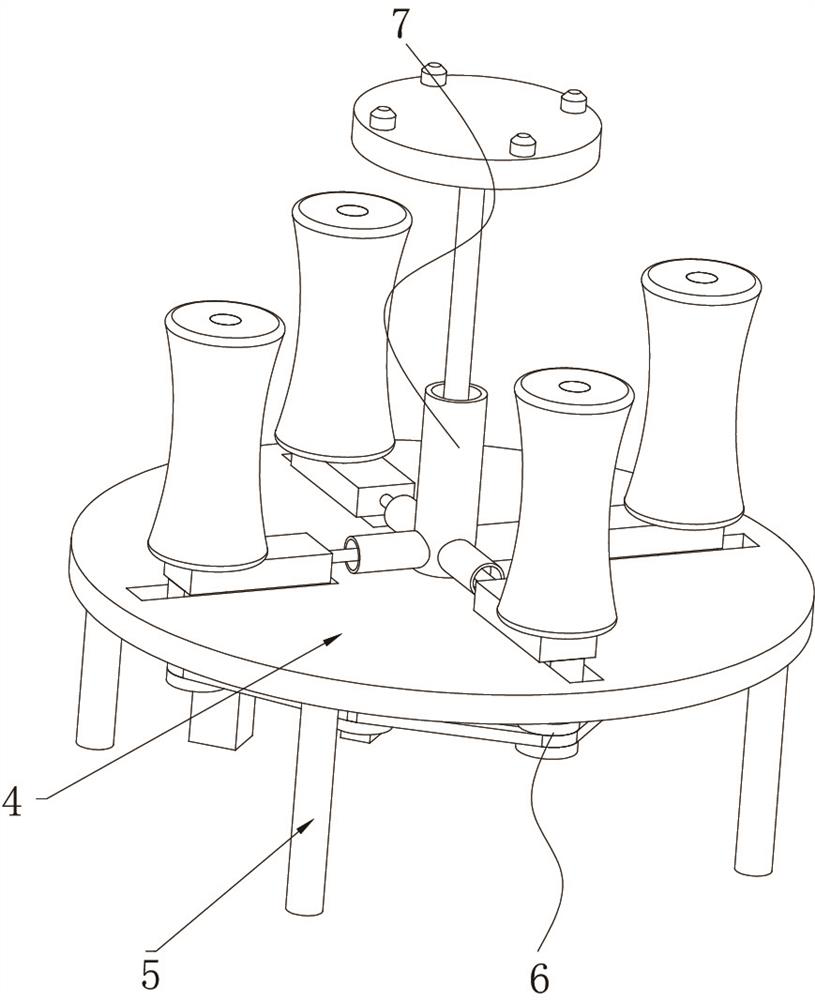

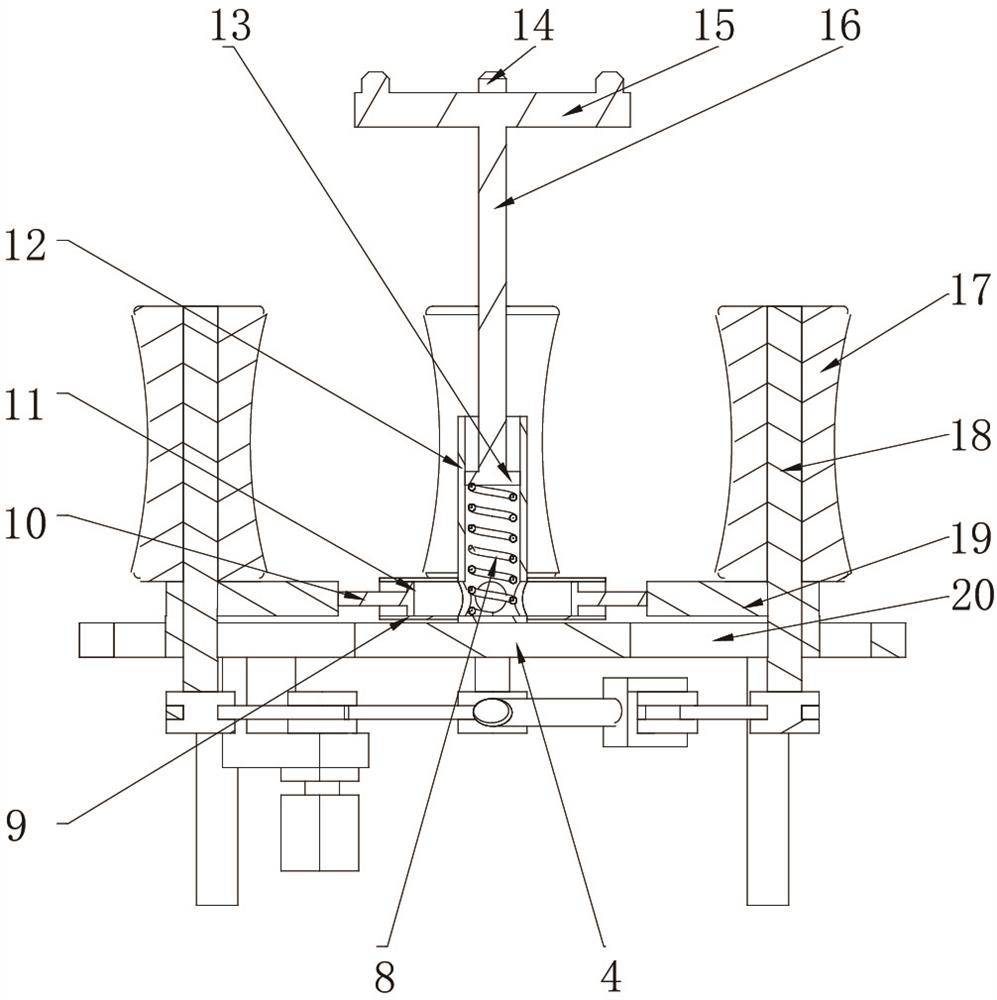

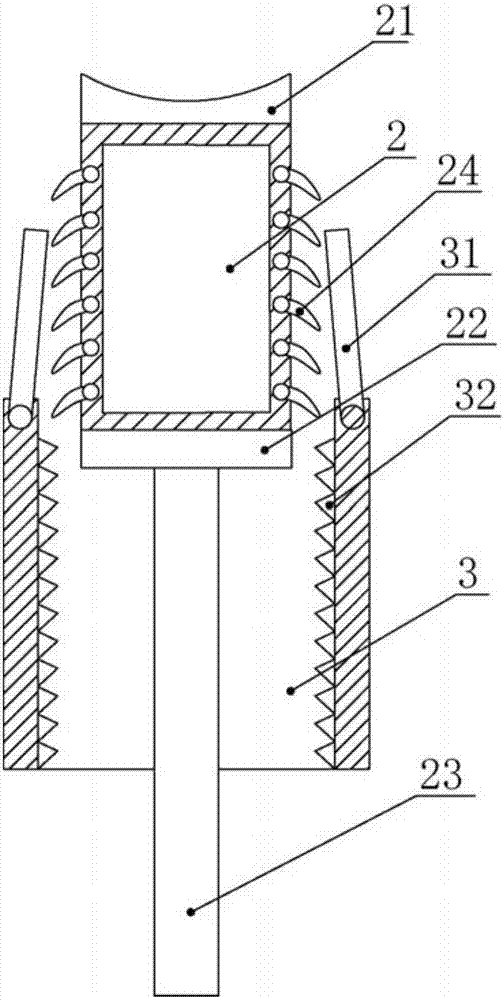

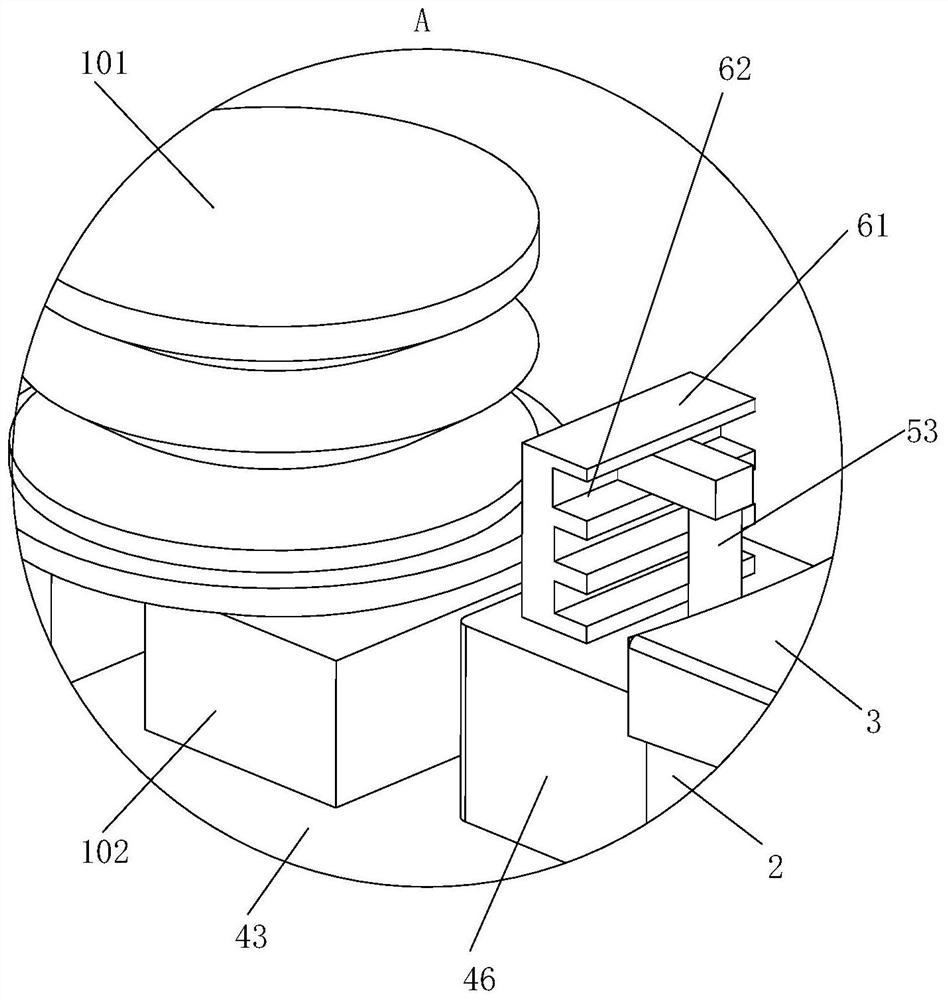

Spraying device for hub production

ActiveCN113663839AImprove synchronicityRealize adaptive adjustmentPretreated surfacesLiquid spraying apparatusMechanical engineeringPiston

The invention discloses a spraying device for hub production, and relates to the technical field of hub spraying. The invention aims to solve the problems of synchronism and efficiency. The spraying device specifically comprises a base and a clamping driving mechanism and a spraying mechanism. The clamping driving mechanism and the spraying mechanism are arranged at the top of the base and matched with each other, and the clamping driving mechanism comprises a supporting seat fixed to the outer wall of the top of the base through supporting legs, a driving assembly and a clamping assembly, wherein the driving assembly and the clamping assembly are arranged on the two sides of the supporting seat and matched with each other. According to the spraying device for hub production, when a hub descends due to gravity, a downward pressing supporting disc descends, so that a second piston descends, the pressure in a cavity of a main cylinder body is increased, a first piston is ejected out, a first connecting rod drives an L-shaped sliding block and a clamping cambered surface roller assembly to slide towards the outer side, the inner ring wall of the hub is clamped and fixed, and when the hub is sprayed, the hub is lifted upwards. A first spring can bounce the second piston, so that the clamping cambered surface roller assembly is shrunk towards the inner side, synchronism of clamping and taking and placing is achieved, and the efficiency is improved.

Owner:永康市跃飞车轮有限公司

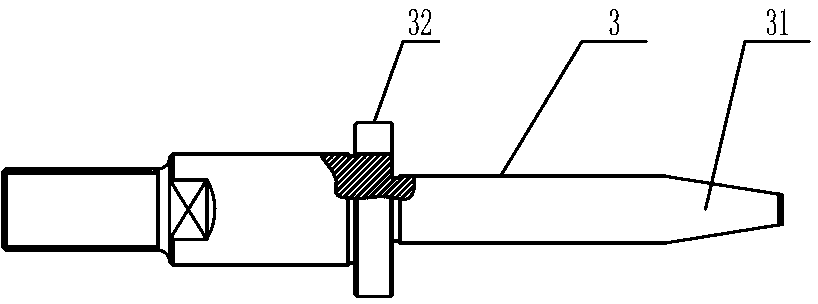

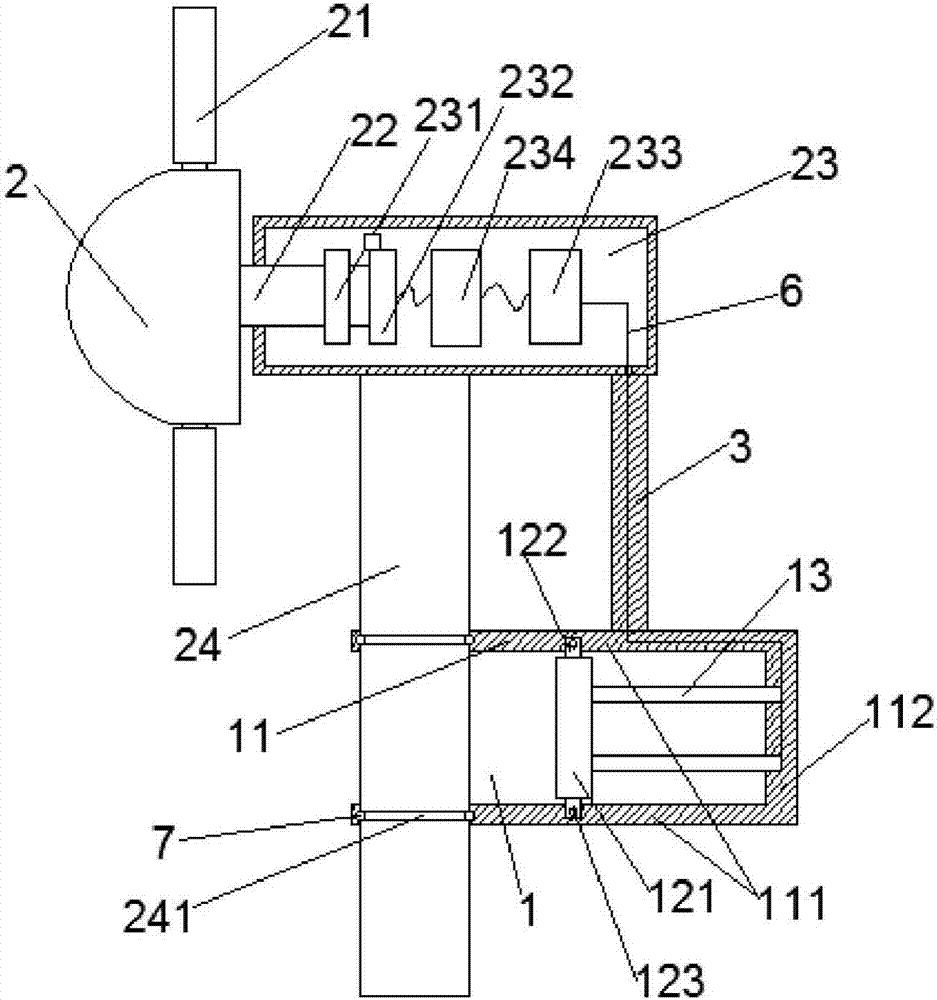

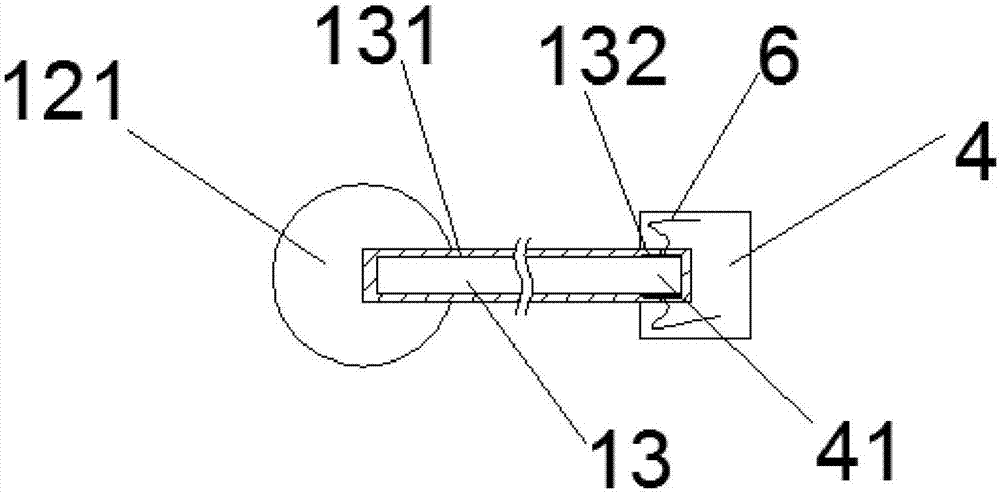

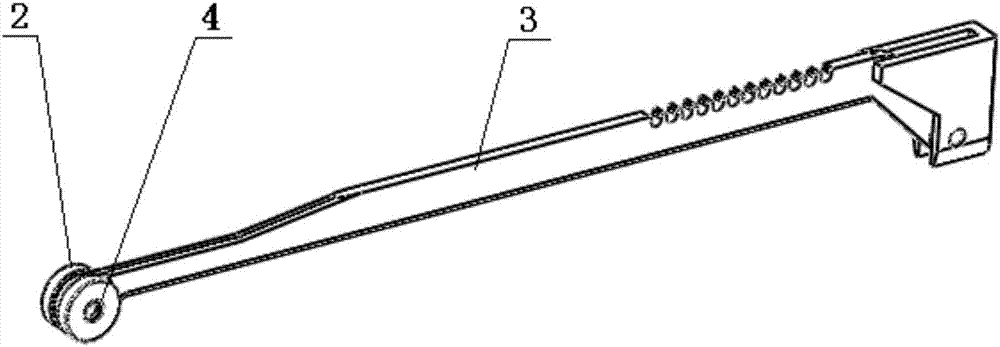

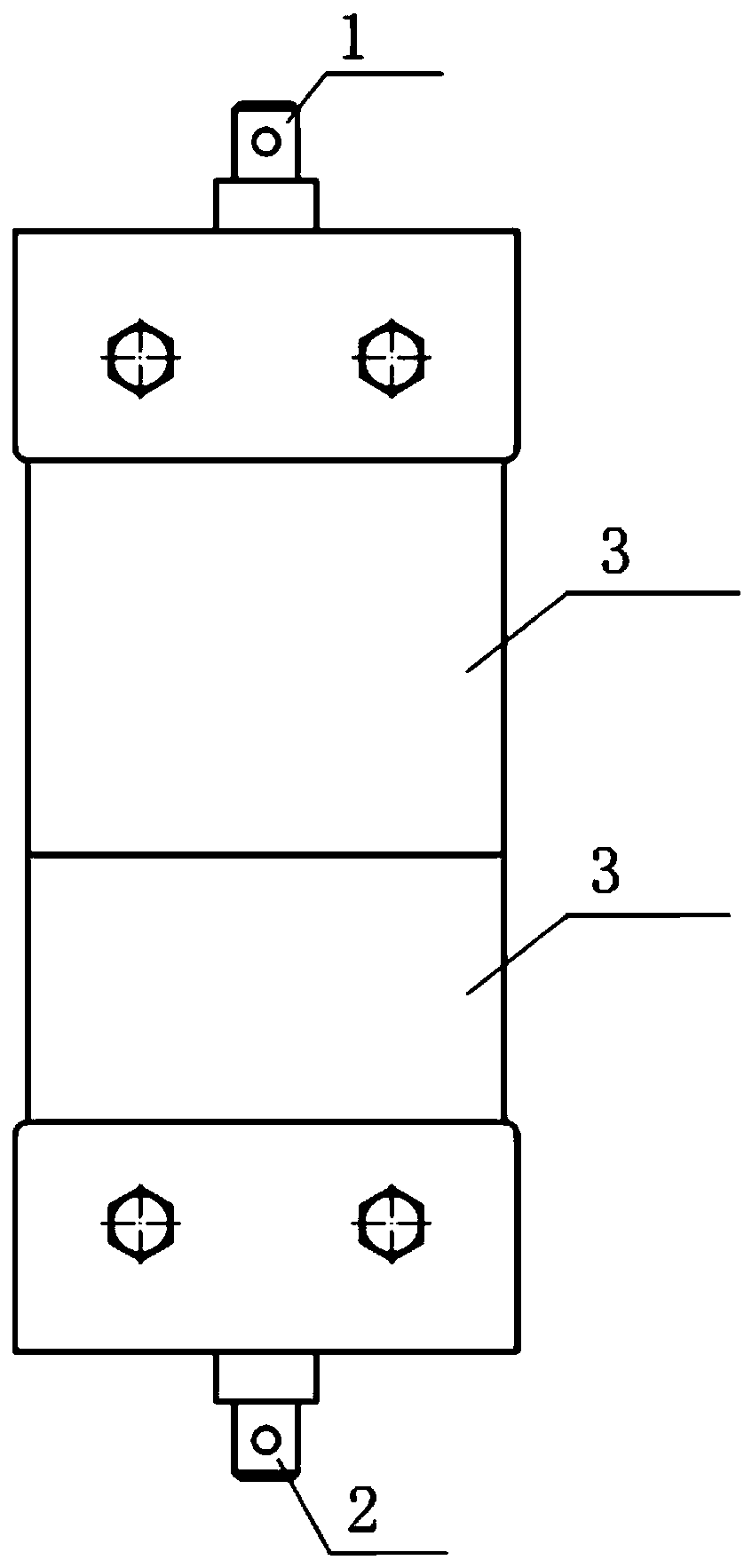

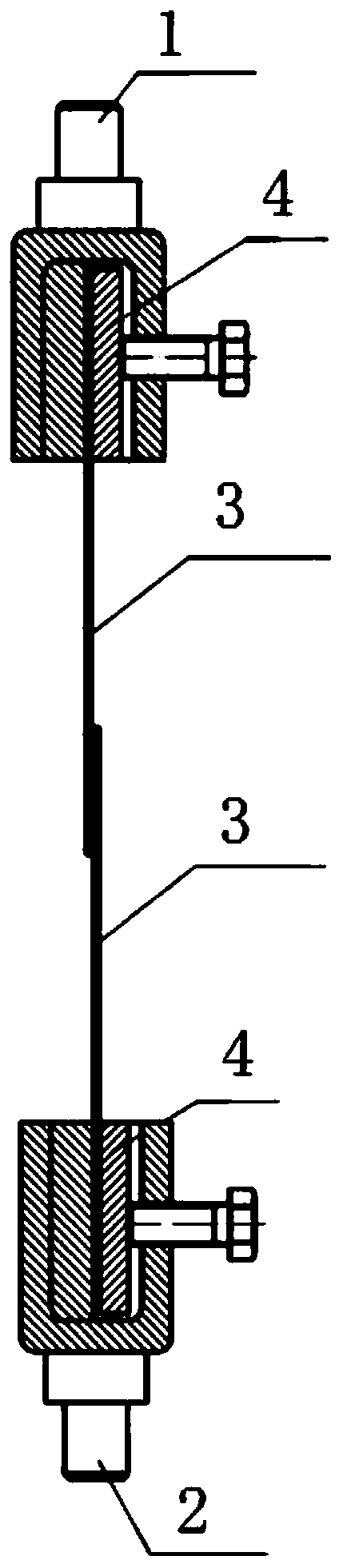

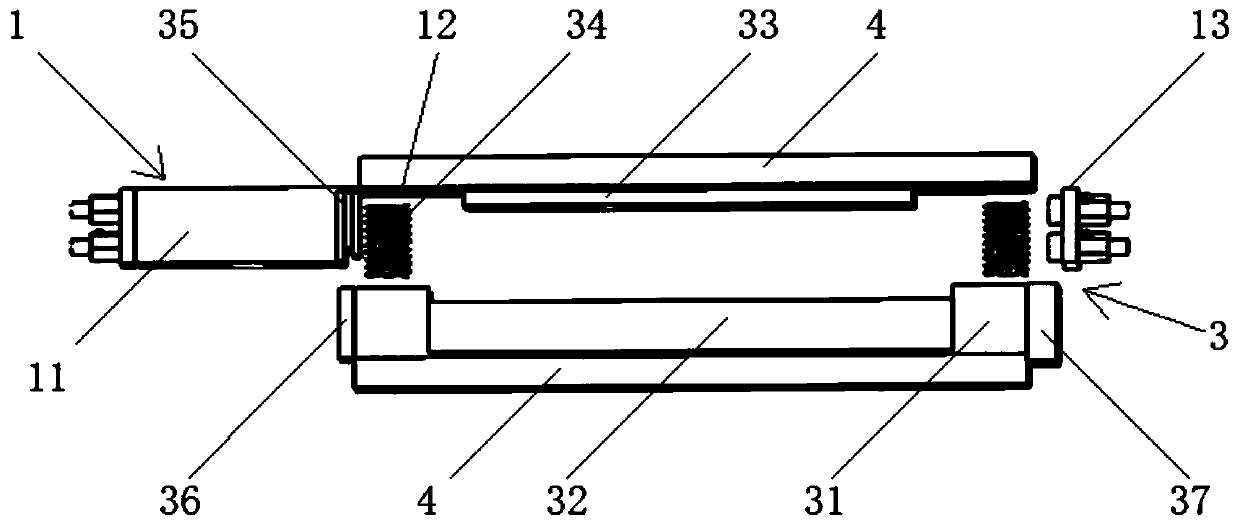

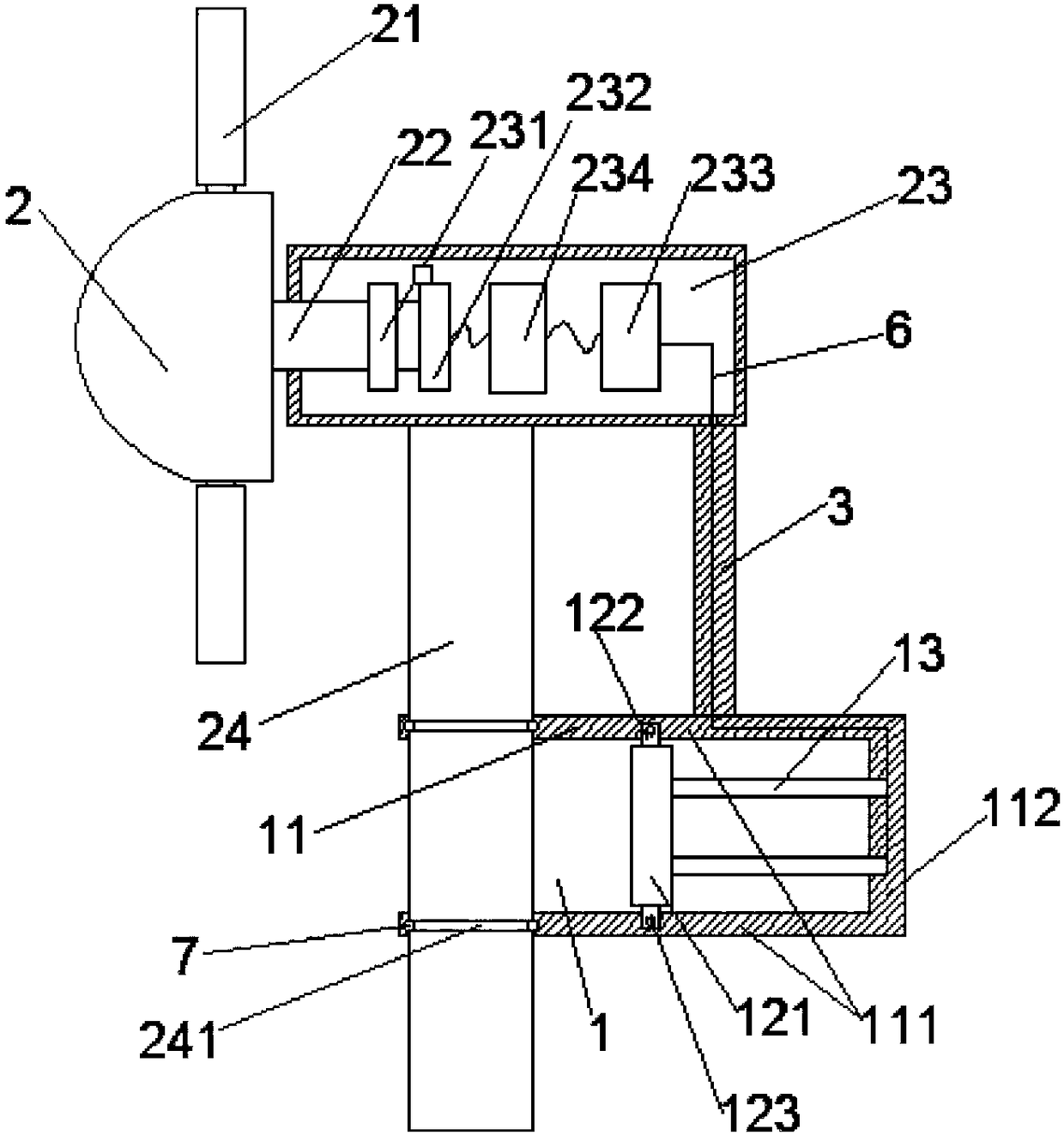

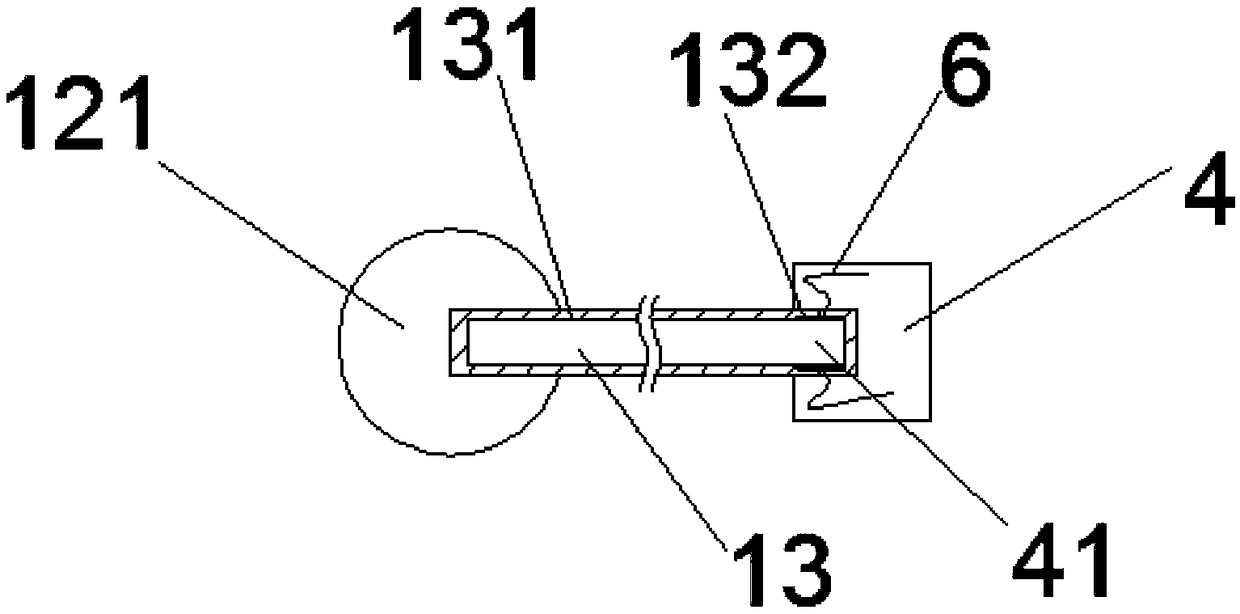

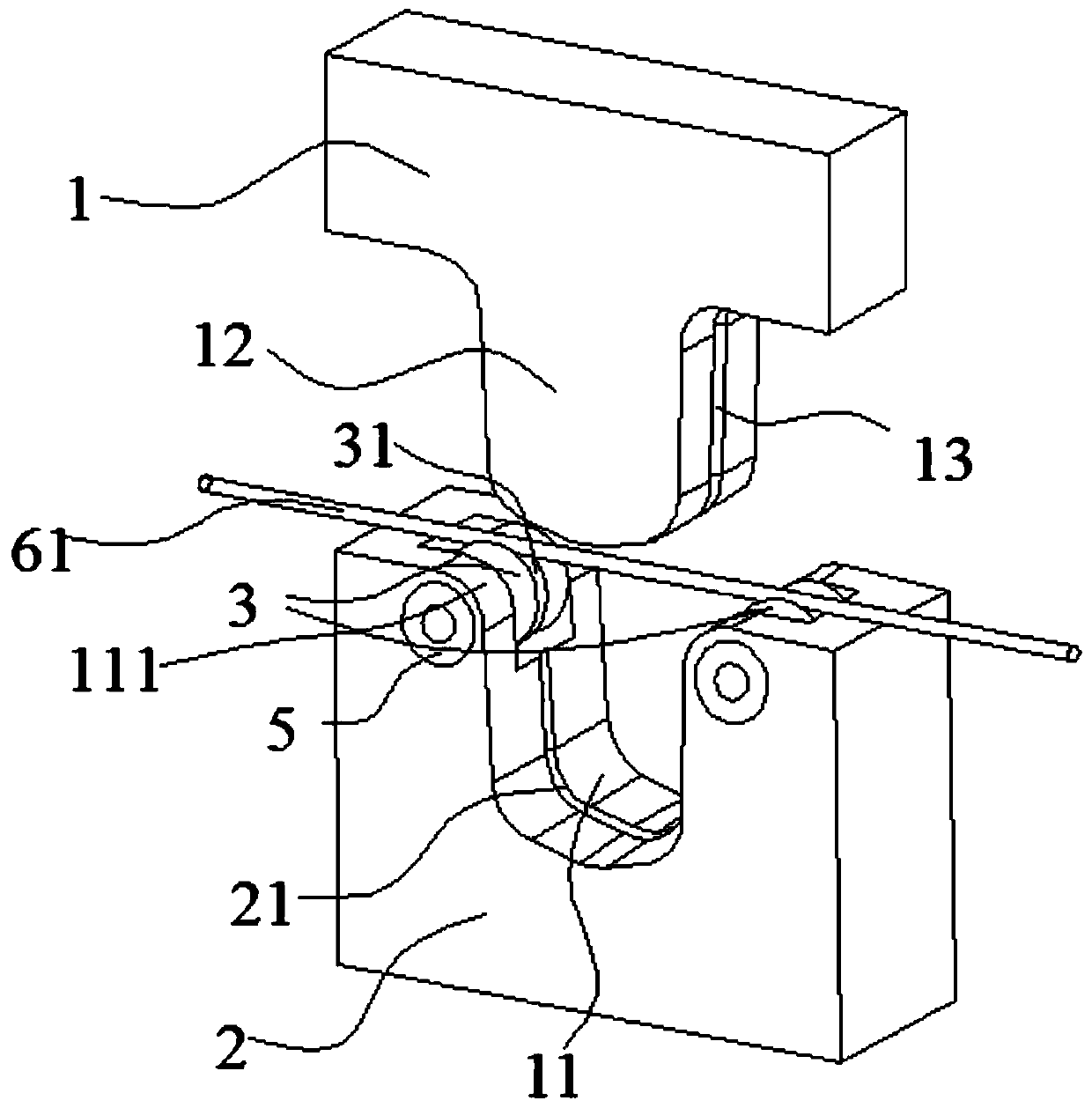

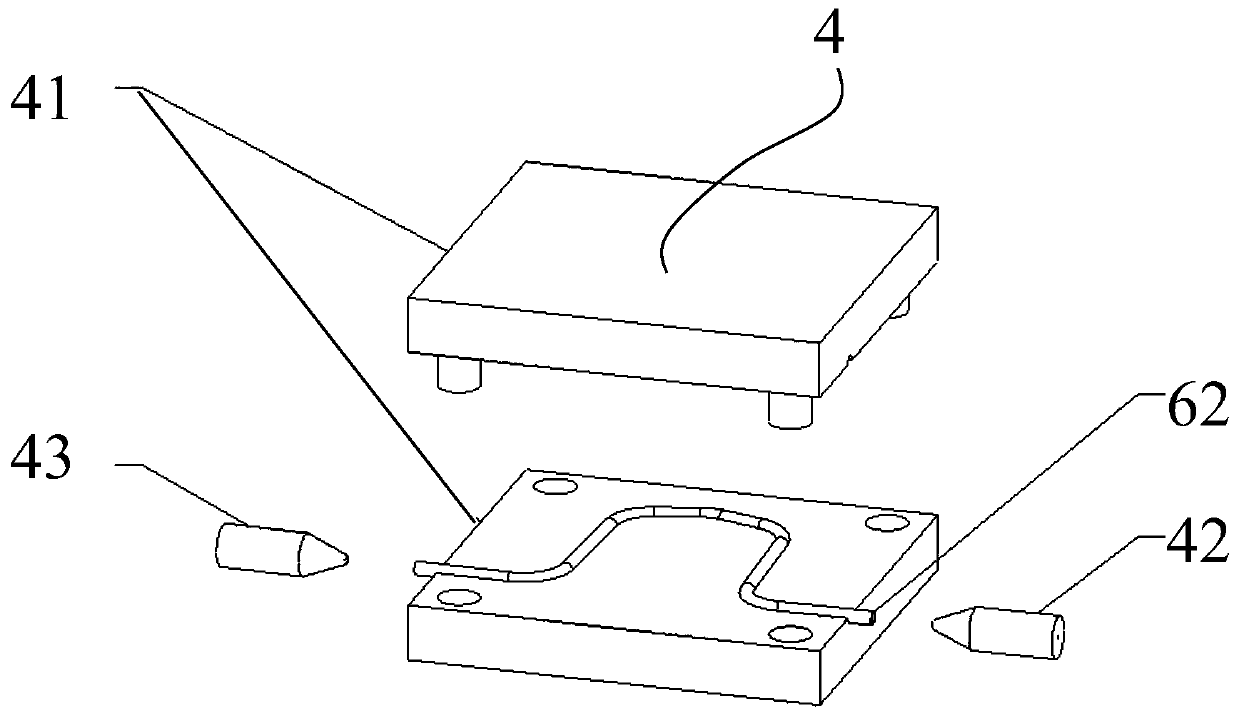

Mechanical assembly drum, anti-package equidistant control device and control method thereof

PendingCN107471705APressure value adjustmentSame pressure valueTyresEngineeringStructural engineering

The invention discloses a mechanical assembly drum, an anti-package equidistant control device and a control method thereof. The anti-package equidistant control device comprises the mechanical assembly drum which comprises anti-package rod devices arranged on two sides of a green tire and a driving device which controls the anti-package rod devices to operate; each of the anti-package rod devices comprises an anti-package rod (3) and a pressure sensor (4) for detecting stress of the anti-package rod (3). The mechanical assembly drum also comprises a comparing device for pressure values of the pressure sensors (4) on the anti-package rods on two sides. The comparing device is in communication connection to the driving device. The anti-package equidistant control device provided by the invention can adjust the pressure values of the anti-package rods effectively, so that the pressure values on two sides of the green tire tend to be same, so that synchronous movement of the anti-package rods on two sides is ensured, the stress on two sides of the green tire is same, and the quality of the green tire is improved.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG

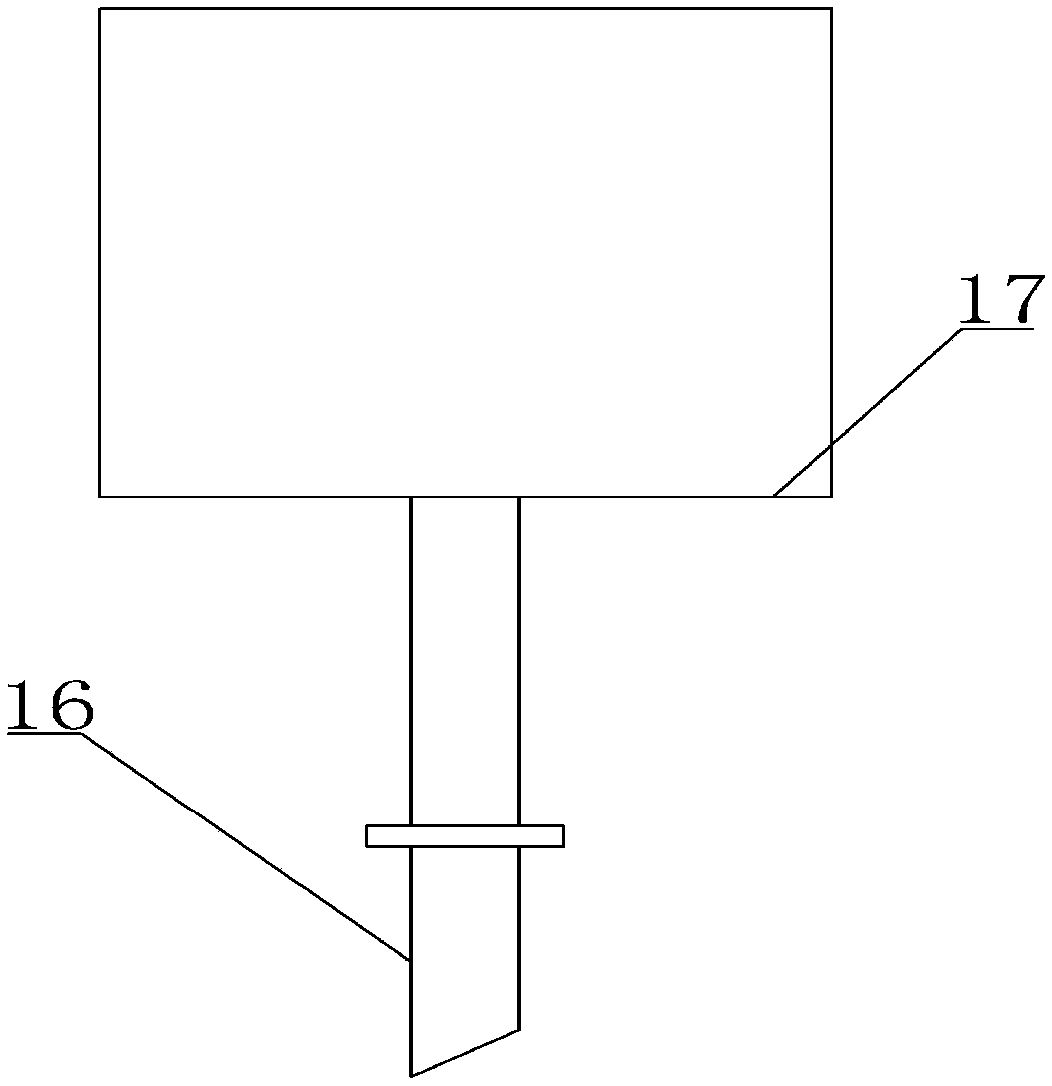

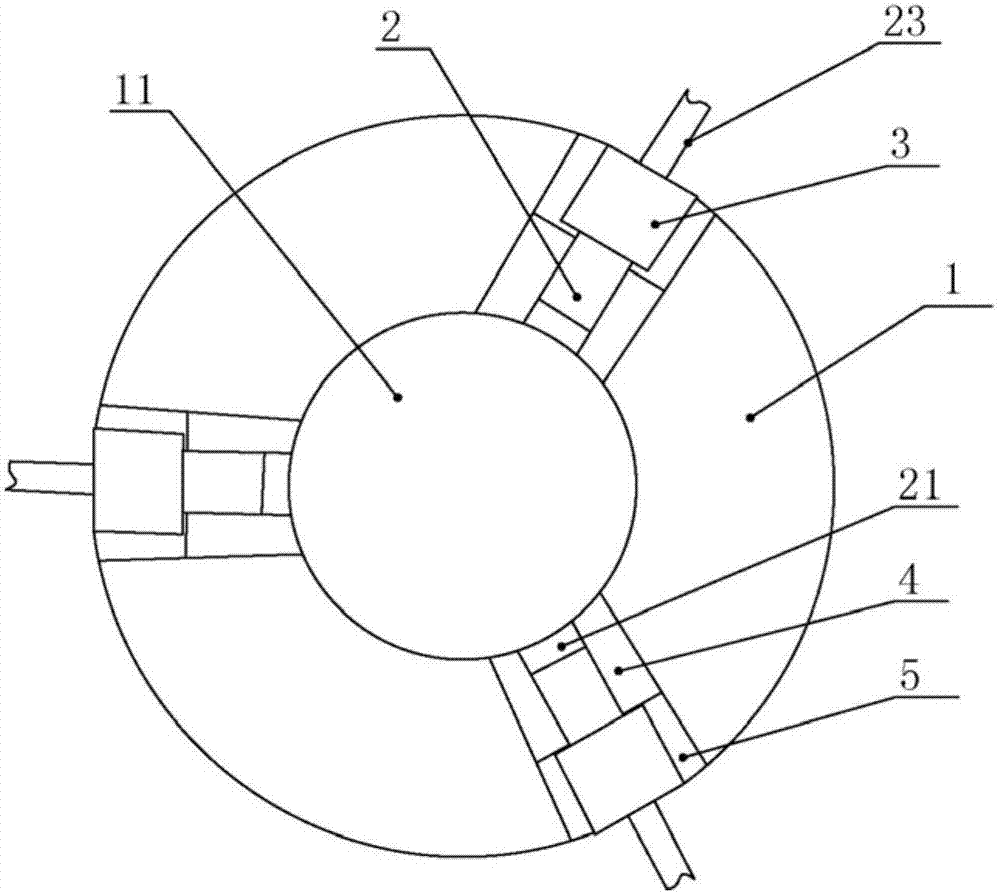

Detection clamp and method for bending capability of flexible screen

ActiveCN106501076AImprove measurement accuracy and speedAvoid scratches or damageStrength propertiesEngineeringExtrusion

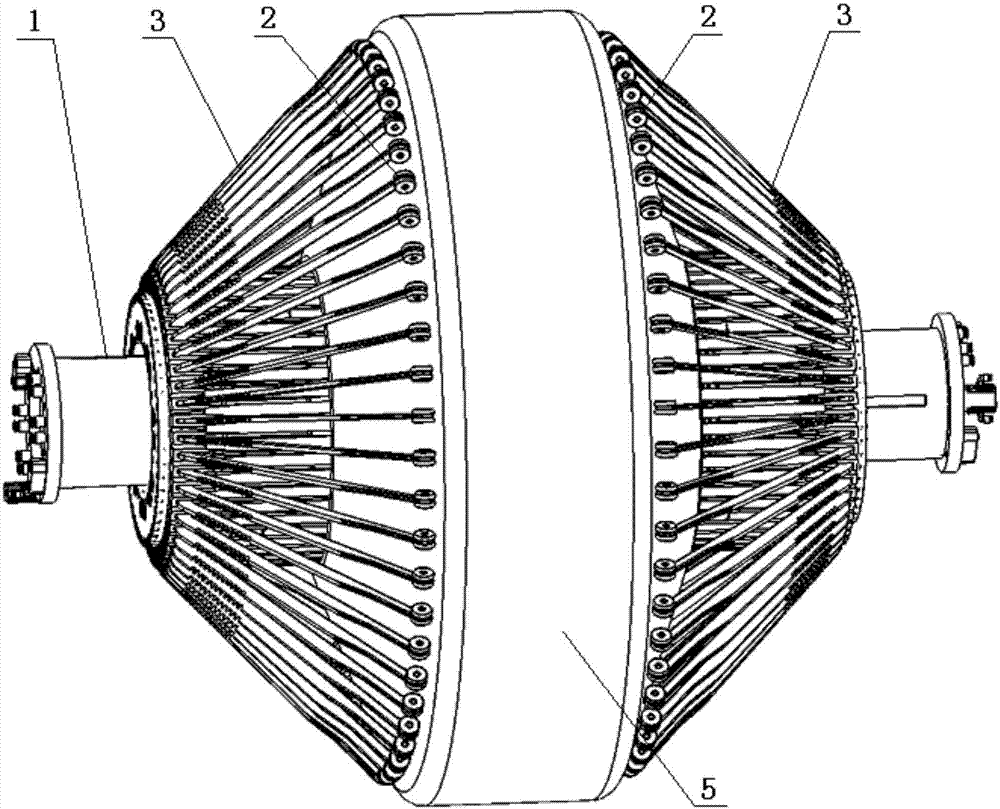

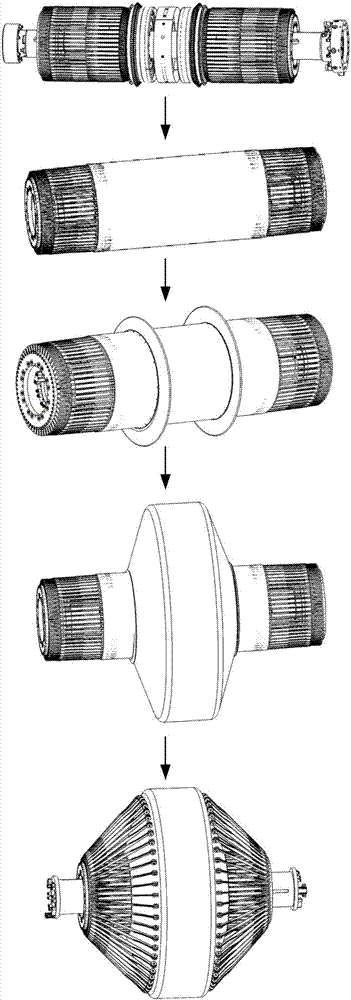

The invention provides a detection clamp for the bending capability of a flexible screen. The detection clamp comprises a clamp unit, an umbrella handle part, hinging seats and hinging umbrella ribs, wherein the clamp unit is of a sector-shaped flexible sandwich structure with two fixed ends and forms a containing space; the clamp unit is combined to form an umbrella surface part; the top of the umbrella handle part is fixed at the center of the umbrella surface part and the bottom end of the umbrella handle part is fixed; the hinging seats sleeve the umbrella handle part and move along the axial direction of the umbrella handle part; the hinging umbrella ribs are arranged along the peripheral direction of the hinging seats and correspond to the clamp unit; one end of each hinging umbrella rib is hinged to the corresponding hinging seat and the other ends of the hinging umbrella ribs are hinged to the corresponding clamp unit; the hinging seats are moved to drive the hinging umbrella ribs to change the radian of the clamp unit. According to the detection clamp provided by the invention, lossless fixation is carried out on an object to be detected in batch and an extrusion and bending test is carried out to test the bendability of the object to be detected; the problems of a traditional manner of clamping a flexible screen substrate that irreversible damage is caused and the detection efficiency is low and the like are solved. The invention further provides a detection method for the bending capability of the flexible screen.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Cable winding device

ActiveCN108154974AThe same degree of closenessIncrease tightnessCable/conductor manufactureEngineeringPush switch

The invention relates to the technical field of power transmission and discloses a cable winding device which comprises a rack, a first motor and a second motor. A cable nailing block is arranged on one side of the rack, a turnplate is rotatably connected on one side, opposite to the cable nailing block, of the rack, a central rod slidably connected with the rack is arranged between the cable nailing block and the turnplate, a first gear is rotatably connected on the outer side of the central rod, an elastic member is fixed on the central rod, grooves are uniformly formed in the rack below theelastic member, the first gear is provided with cable passing holes symmetric according to the central rod and meshed with a second gear positioned above the first gear, the second gear is fixed on an output shaft of a second motor, the second motor is fixed on a linear motor module arranged on the rack, a button switch electrically connected with the linear motor module is arranged in each groove, the cable nailing lock can slide on the rack along with the central rod, and the first motor and the second motor rotate synchronously. The cable winding device is simple in structure and can ensure tight lead inter-twisting, thereby improving cable quality.

Owner:重庆博创知识产权运营有限公司

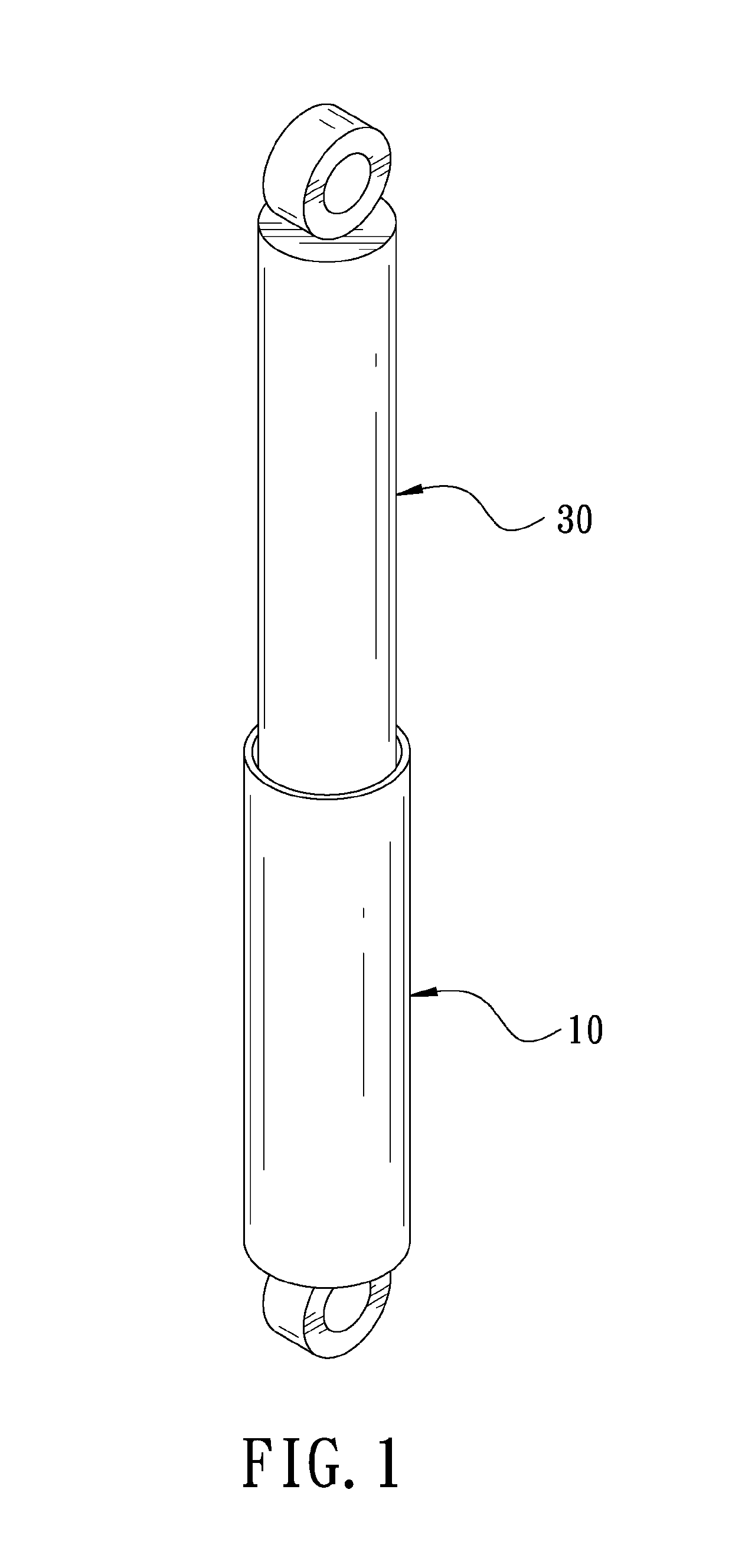

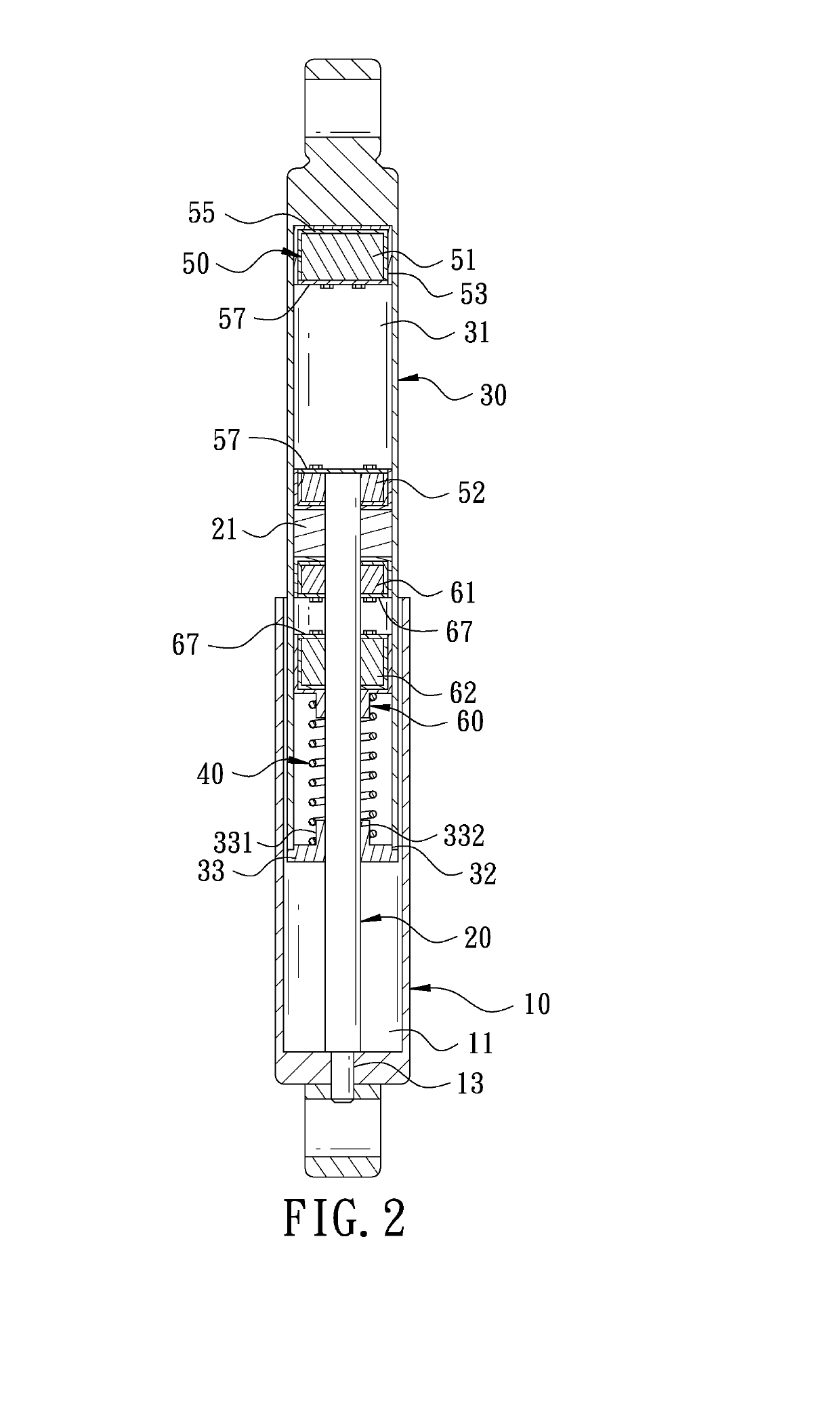

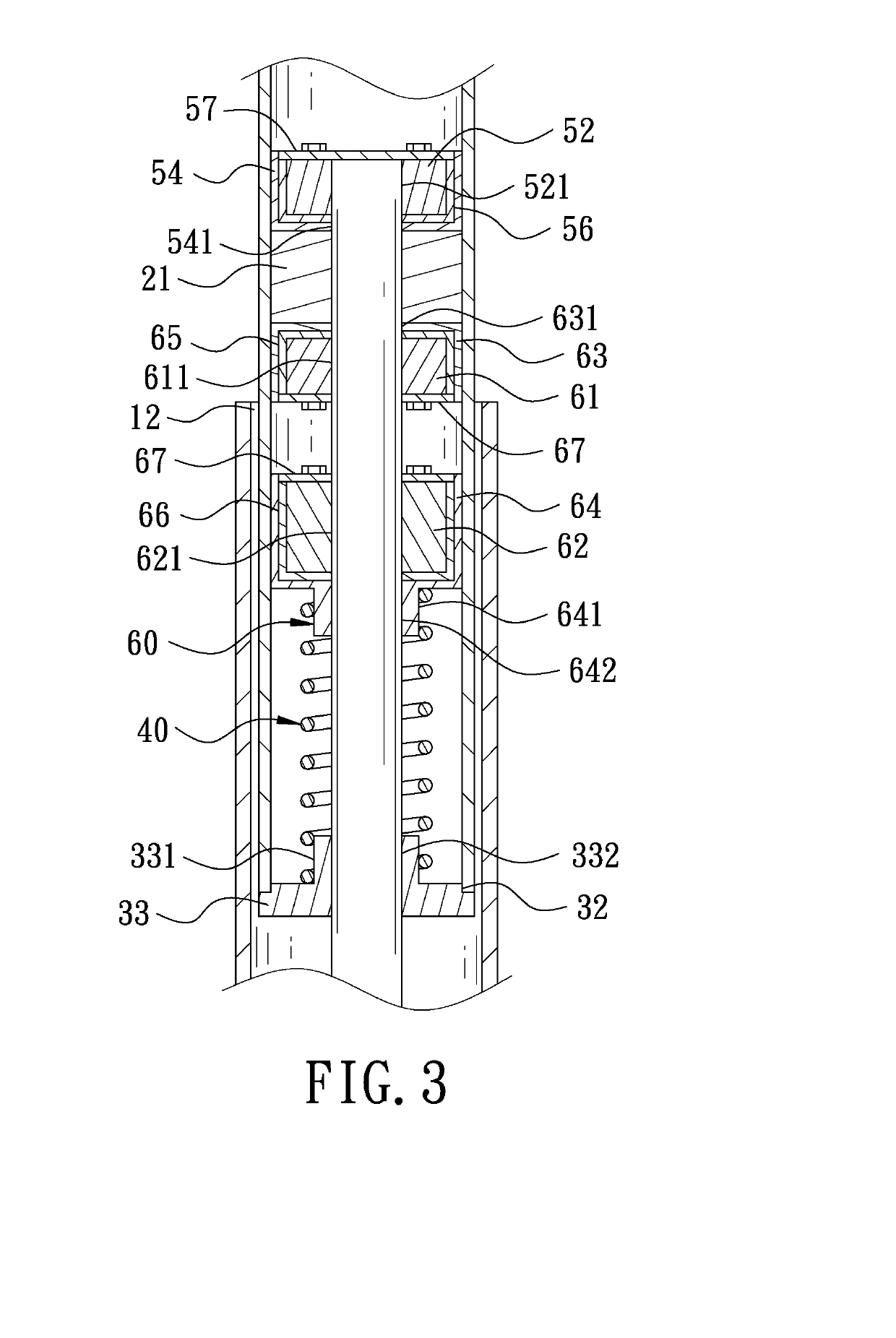

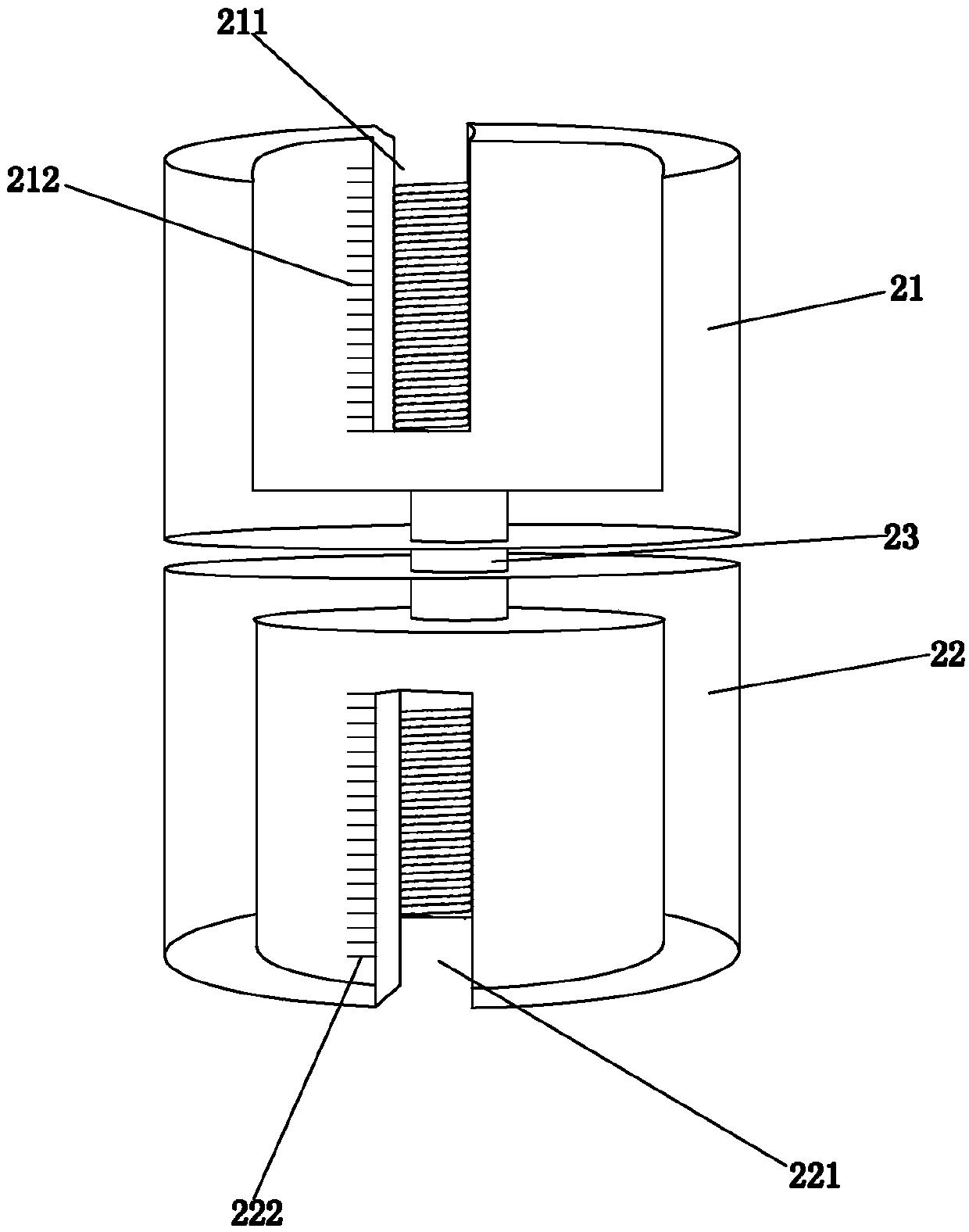

Magnetic suspension shock absorber

InactiveUS20190234480A1Reduce manufacturing costMaintain balanceNon-rotating vibration suppressionSprings/dampers design characteristicsMagnetic polarityShock absorber

A magnetic suspension shock absorber is composed of an outer telescopic cylinder, a shaft rod, an inner telescopic cylinder and two sets of magnetic suspension units. Each set of magnetic suspension unit contains two magnets, and the corresponding surfaces of two magnets of each magnetic suspension unit are the same magnetic polarity. The magnets of two sets of magnetic suspension units are respectively combined with the outer telescopic cylinder, the shaft rod and the inner telescopic cylinder. Thus, when the inner telescopic cylinder is impacted by external force, two magnets of one magnetic suspension unit will be close to each other and produce mutual repulsion, thus achieving buffering and shock absorbing effects.

Owner:SUHDER IND

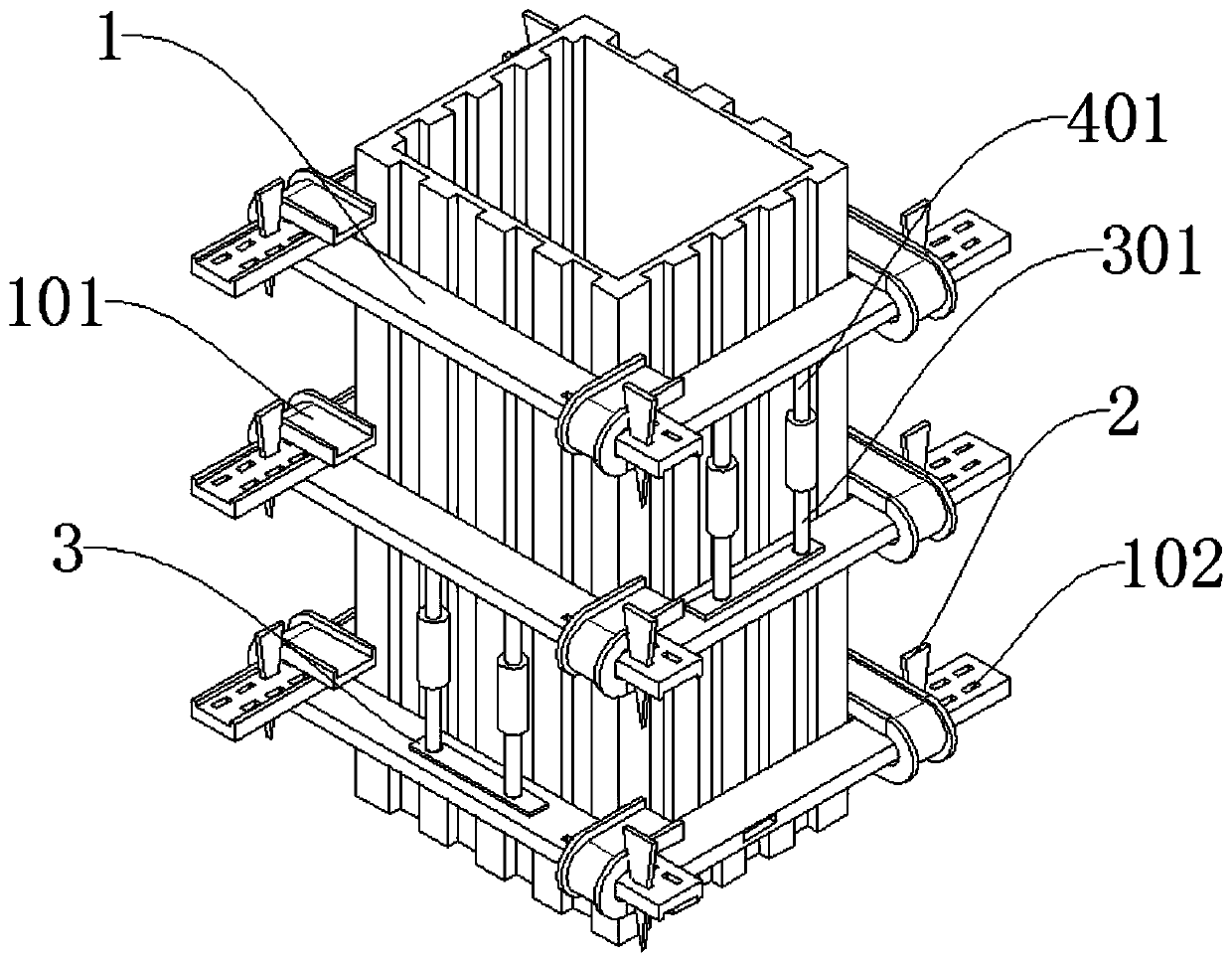

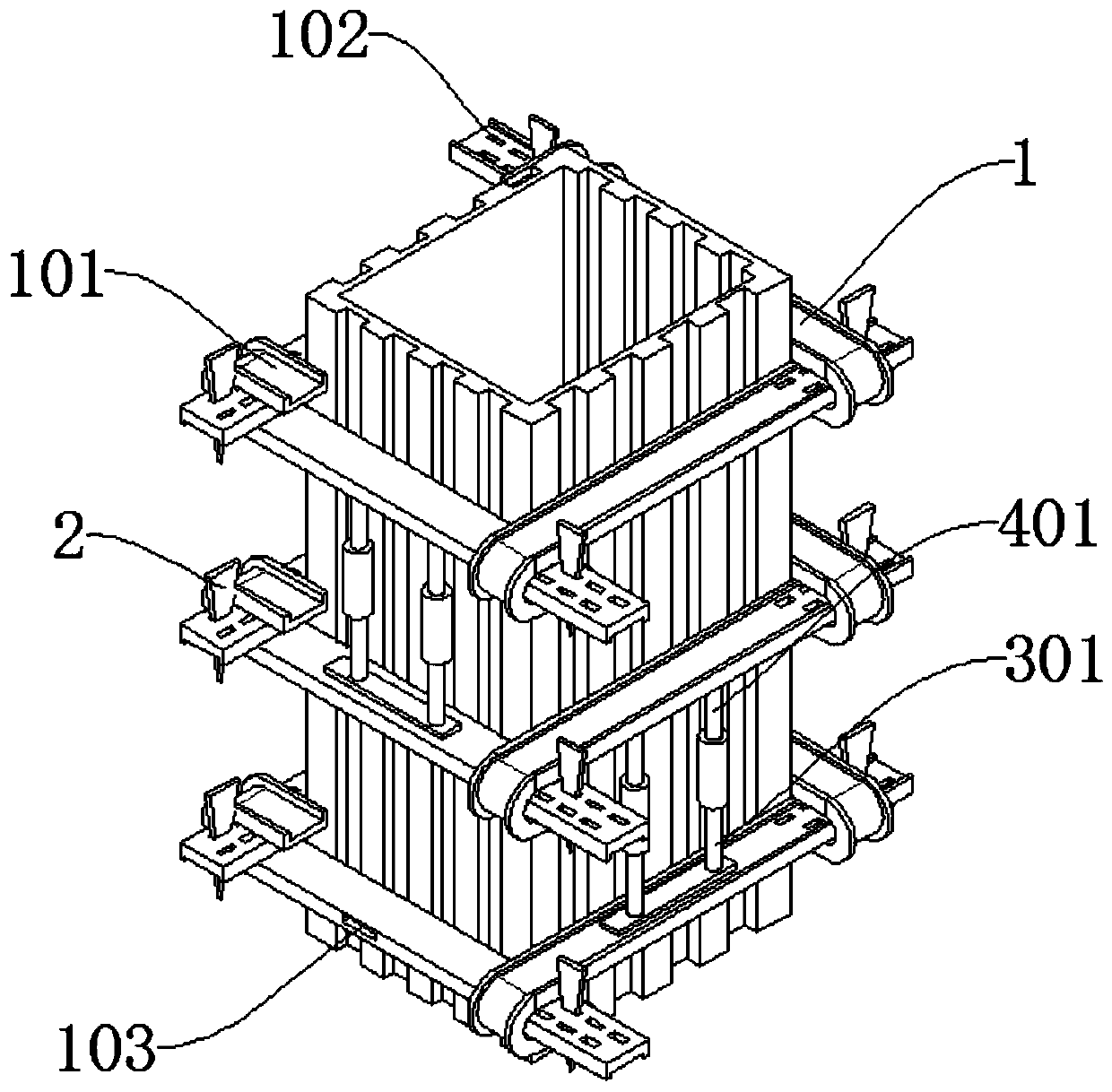

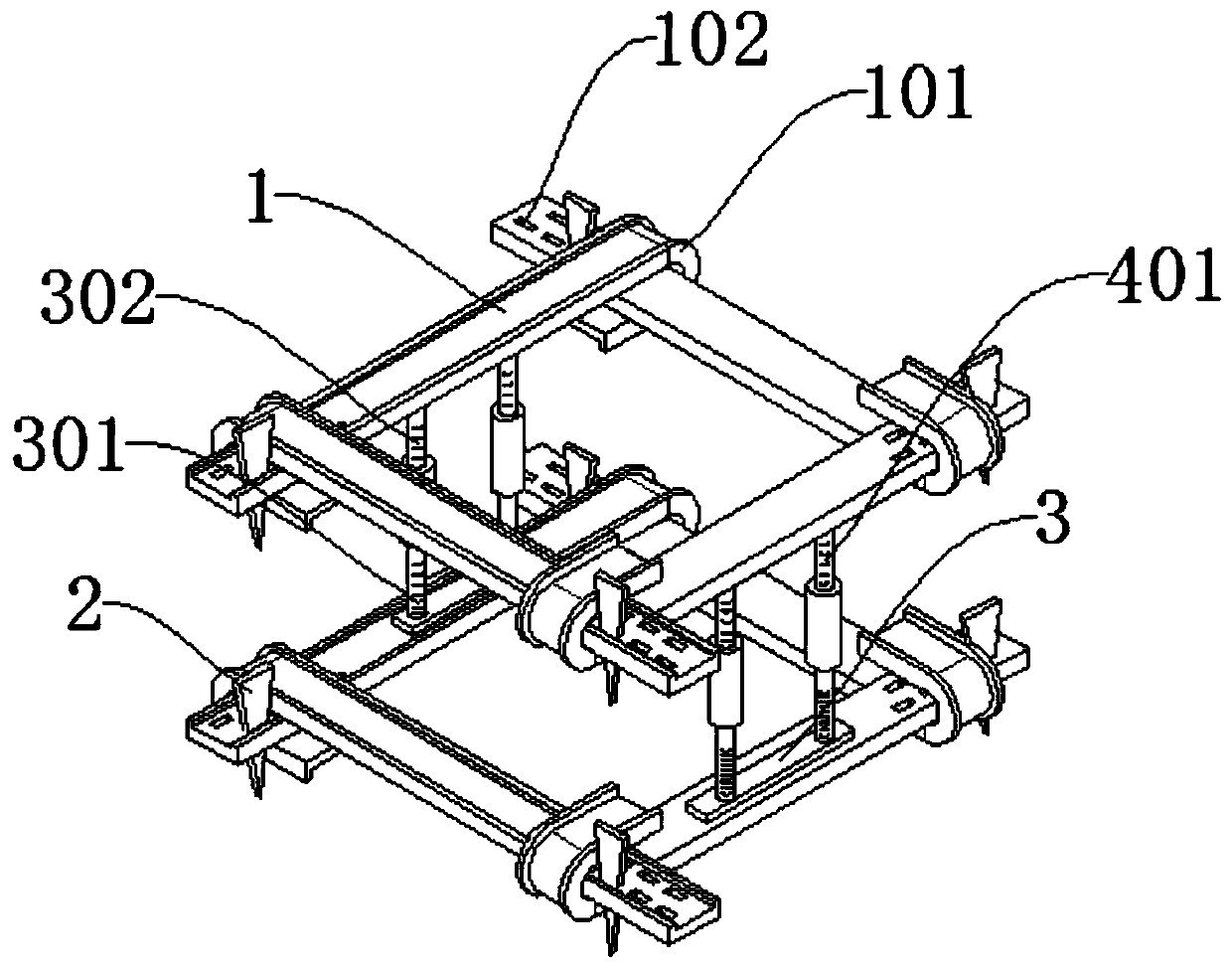

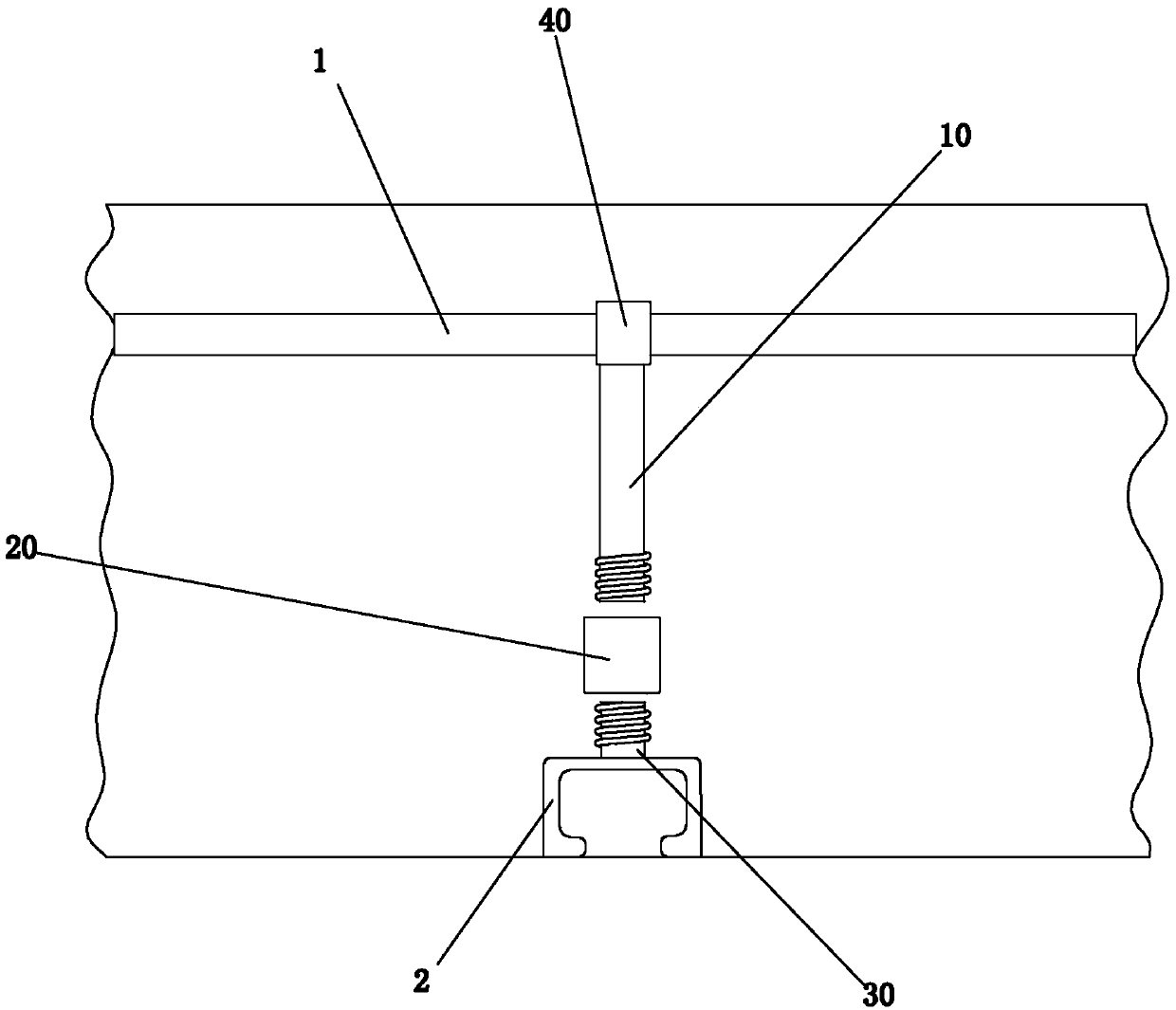

Shaping reinforcing part of square column template

InactiveCN110424728APlay the role of reinforcementEven by forceForms/shuttering/falseworksEngineering

Owner:JINCHEN GROUP

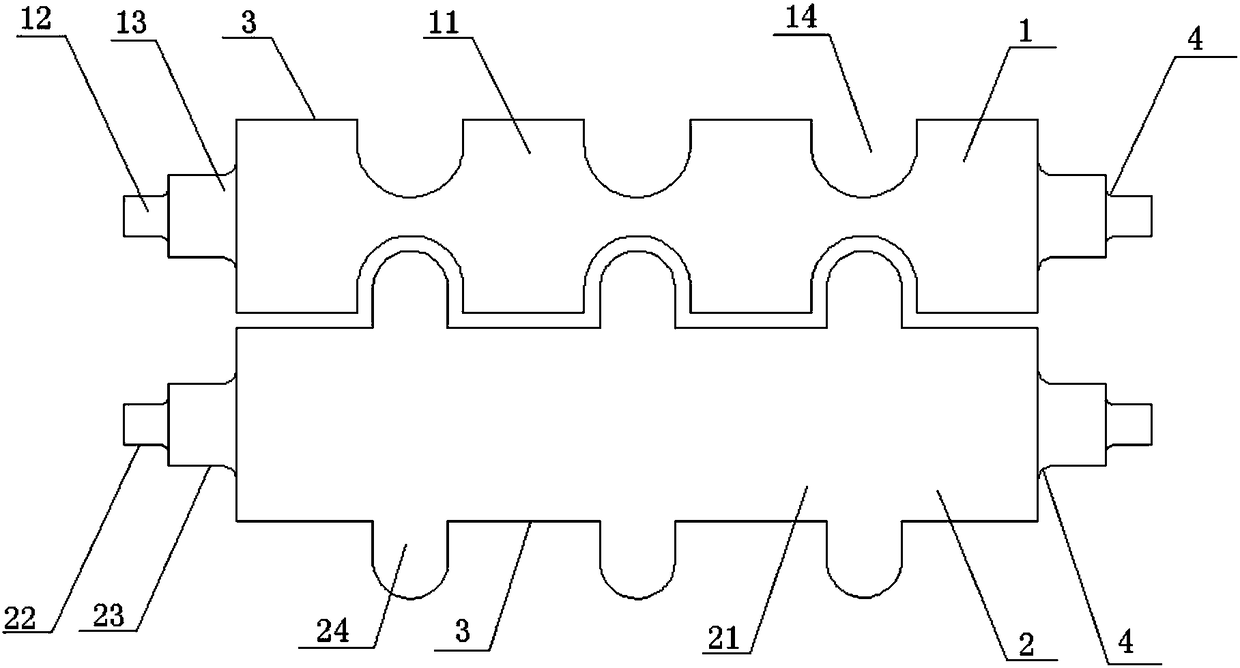

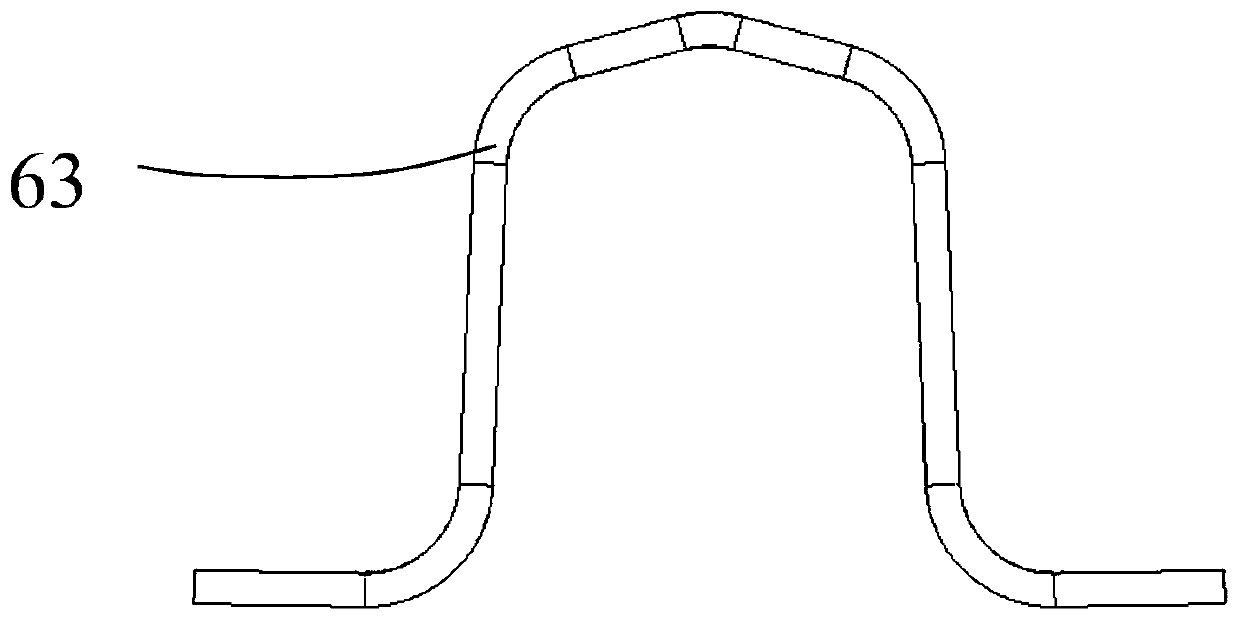

Novel graphite semi-steel bar and finished product roller and production method thereof

PendingCN108165894AImprove microstructureImprove plasticityFurnace typesRollsGraphitePulp and paper industry

The invention relates to a novel graphite semi-steel bar and finished product roller assembly, which comprises an upper roller and a lower roller. The upper roller comprises an upper roller body, andan upper roller neck and an upper bearing retainer roll neck located on two ends of the upper roller body; the lower roller comprises a lower roller body, and a lower roller neck and a lower bearing retainer roll neck arranged correspondingly; 2 to 5 'U'-shaped grooves surrounding the upper roller body are arranged on the upper roller body at intervals; 2 to 5 inverted 'U'-shaped bulges surrounding the lower roller body are arranged on the lower roller body at corresponding intervals; a smooth platform is arranged between each two adjacent grooves or bulges; and the upper roller body and the lower roller body are mutually meshed. According to the novel graphite semi-steel bar and finished product roller assembly provided by the invention, through the inverted 'U'-shaped bulges and the 'U'-shaped grooves of the roller bodies, bars and parts with required shapes are rolled, and meanwhile, through adjusting a distance between the two rollers, the thicknesses of the rolled bars and partsare adjusted, so that the production efficiency is improved.

Owner:常州市瑞宏轧辊有限公司

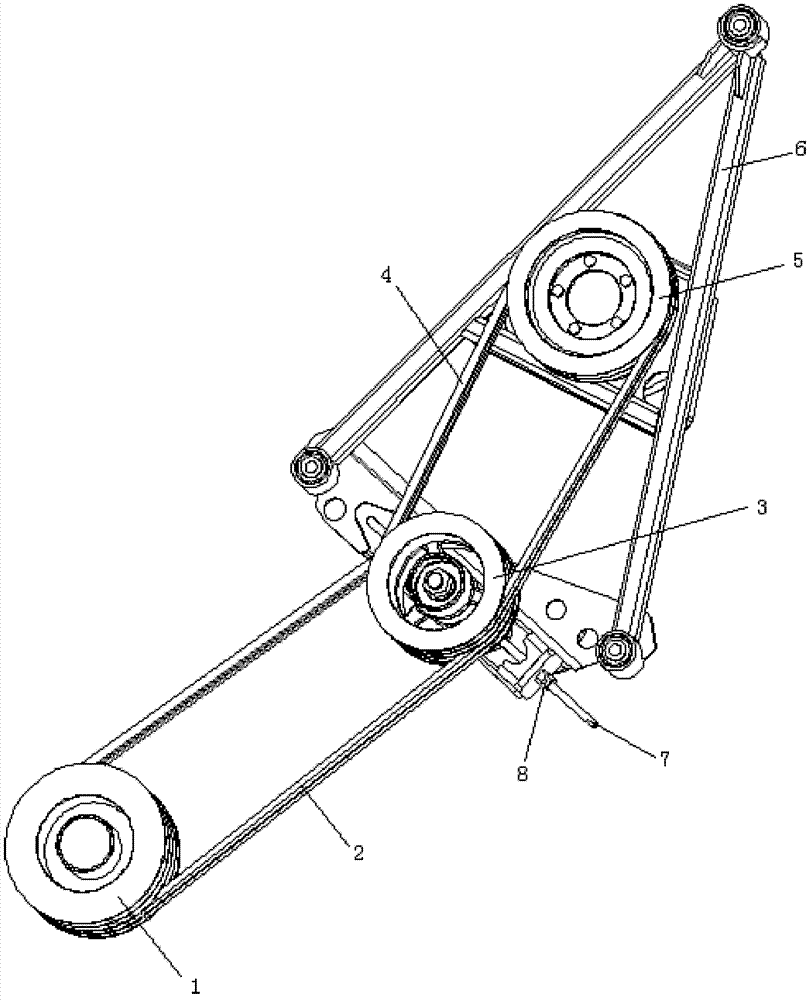

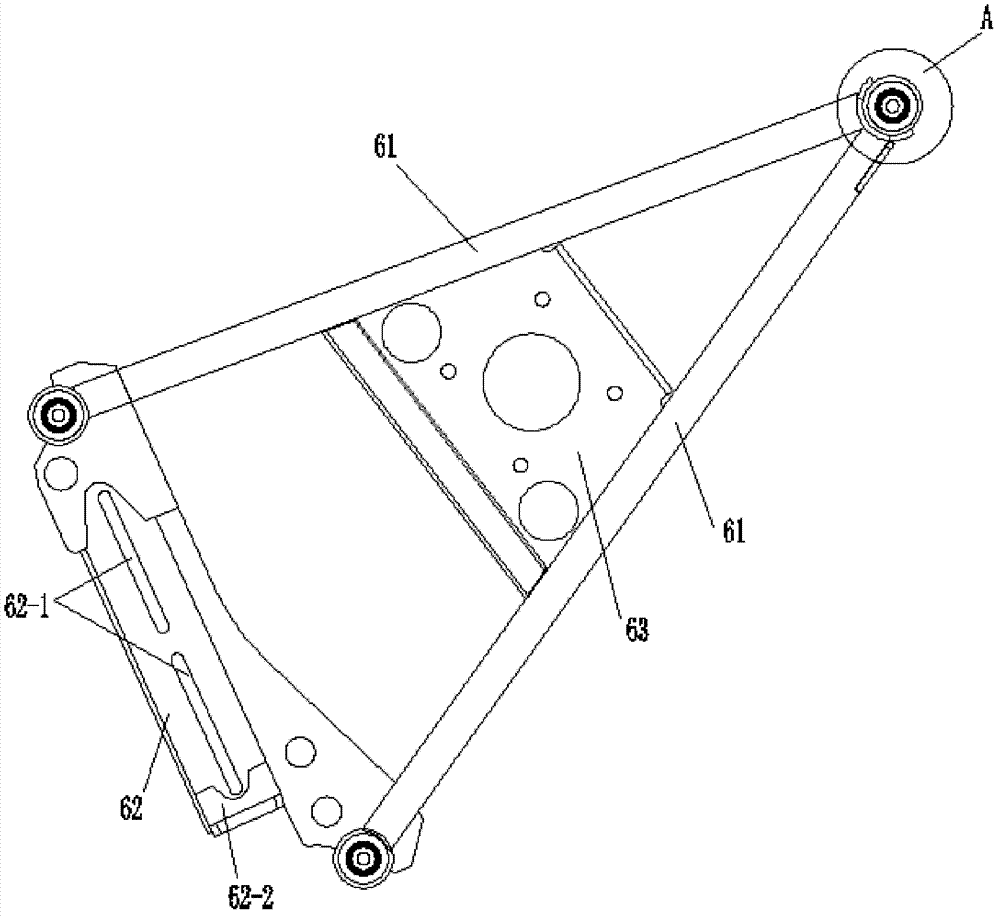

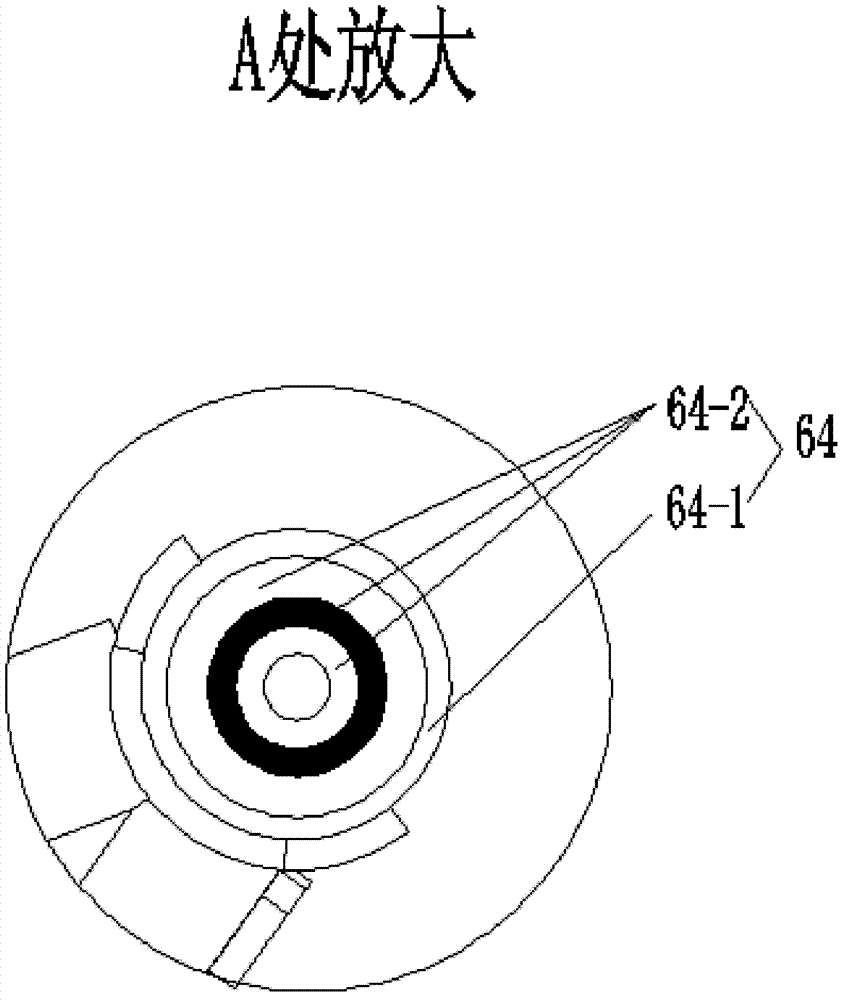

Bus fan-belt transmission mechanism

ActiveCN103089390AImprove stabilitySuitable for mass productionGearingMachines/enginesCrankshaftPulley

The invention discloses a bus fan-belt transmission mechanism which comprises a crankshaft pulley, a crankshaft belt, a central pulley assembly, a fan belt, a fan pulley assembly and a triangular frame assembly. A central pulley of the central pulley assembly is a double-layer pulley. The crankshaft belt surrounds the crankshaft pulley and a layer of the central pulley. The fan belt surrounds the other layer of the central pulley and the fan belt pulley assembly. The triangular frame assembly comprises two inclined beams, a central pulley mounting support and a fan pulley mounting support. The central pulley mounting support is taken as a base edge to form a triangle frame of the triangular frame assembly with the two cant beams. The fan pulley mounting support is mounted in the center of the triangle frame. The fan pulley mounting support and the central pulley mounting support are mounted in the triangular frame assembly, so that assembly accuracy of the fan pulley mounting support and the central pulley mounting support on the triangular frame assembly is improved, and the fan belt can be well matched with two belt grooves. The bus fan-belt transmission mechanism is simple to assemble, and structure stability thereof is improved.

Owner:北汽重型汽车有限公司

Method for testing lap joint fracture resistance of bamboo skin rolls

PendingCN110715852ATrue reflection of actual performanceThe test method is simple and fastMaterial strength using tensile/compressive forcesTest sampleLap joint

The invention discloses a method for testing lap joint fracture resistance of bamboo skin rolls. The method comprises the following steps: preparing a sample: cutting at least two to-be-tested samplesfrom a plurality of bamboo skin rolls, wherein the to-be-tested samples comprise an upper roll, a lower roll and a lap joint surface; clamping two ends of each bamboo skin roll to two ends of a clampby taking the lap joint as the center, mounting the bamboo skin rolls on a tensile testing machine after clamping, uniformly and continuously loading the sample until the sample is fractured, and reading and recording the fracture force F during fracture; judging that the lap joint fracture force F of each sample is greater than or equal to Fm or F is less than Fm, recording the number S of the samples with F being less than Fm in the bamboo skin rolls, comparing S with M, judging that the bamboo skin rolls are qualified when S is less than or equal to M, otherwise, judging that the bamboo skin rolls are unqualified, wherein Fm is the minimum value of the set lap joint fracture force, and M is the maximum number of the samples with unqualified performance when the samples are qualified. According to the testing method, the lap joint fracture resistance of the bamboo skin rolls can be accurately and reasonably reflected, and the qualification of the fracture resistance of the bamboo skin rolls can be conveniently screened.

Owner:中林鑫宙竹缠绕发展有限公司

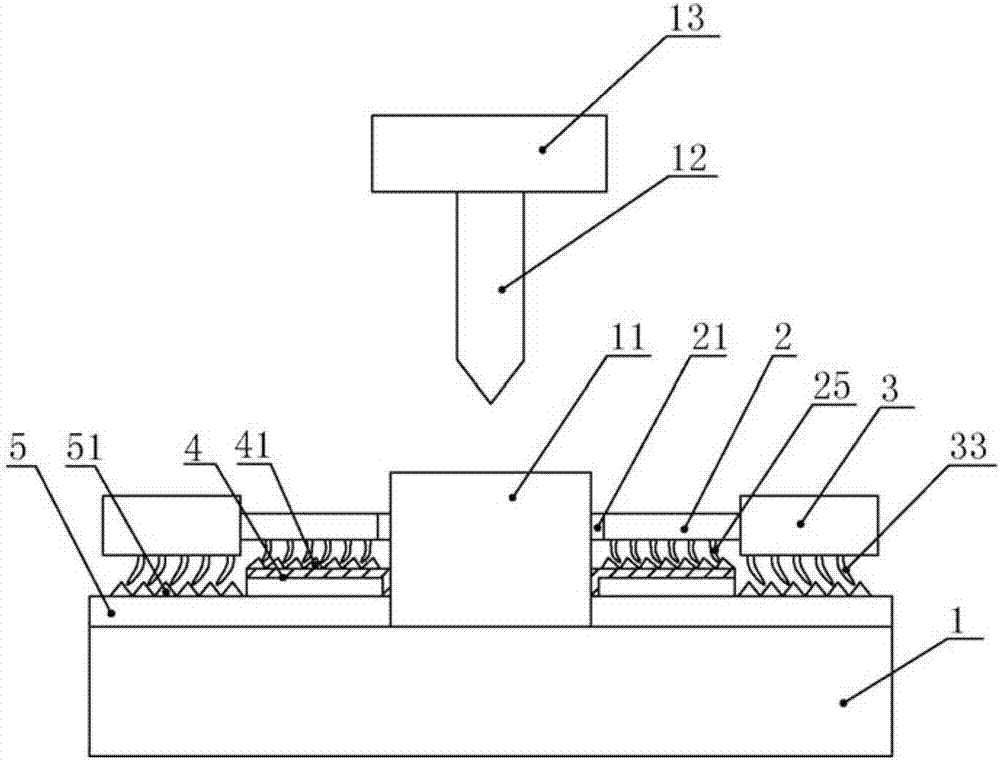

Positioning stamping die

InactiveCN107983861APrevent movementQuality assuranceMetal-working feeding devicesPositioning devicesEngineeringStamping process

The invention relates to a die, in particular to a positioning stamping die. The positioning stamping die comprises an upper die, wherein a stamping head is connected under the upper die, and a lowerdie is arranged below the stamping head; a plurality of first fixing plates are arranged on the lower die, and a plurality of first fixing teeth are arranged on the upper surface of each first fixingplate; a plurality of first clamping rods are movably arranged on the outer side of the lower die, a plurality of first pawls which can be matched with the first fixing teeth are arranged at the bottoms of the first clamping rods, and the side walls of the ends, close to the first fixing plates, of the first clamping rods are hinged to baffles; a plurality of third fixing teeth are arranged on theinner walls of the first clamping rods, and second clamping rods are arranged in the first clamping rods in a sliding mode; and second pawls capable of being matched with the third fixing teeth are arranged on the two sides of the second clamping rods, and a plurality of third pawls which can be matched with the second fixing teeth are arranged at the bottoms of the second clamping rods. According to the positioning stamping die, the problem that a workpiece can move in the stamping process is solved.

Owner:重庆市合川区云天机械制造有限公司

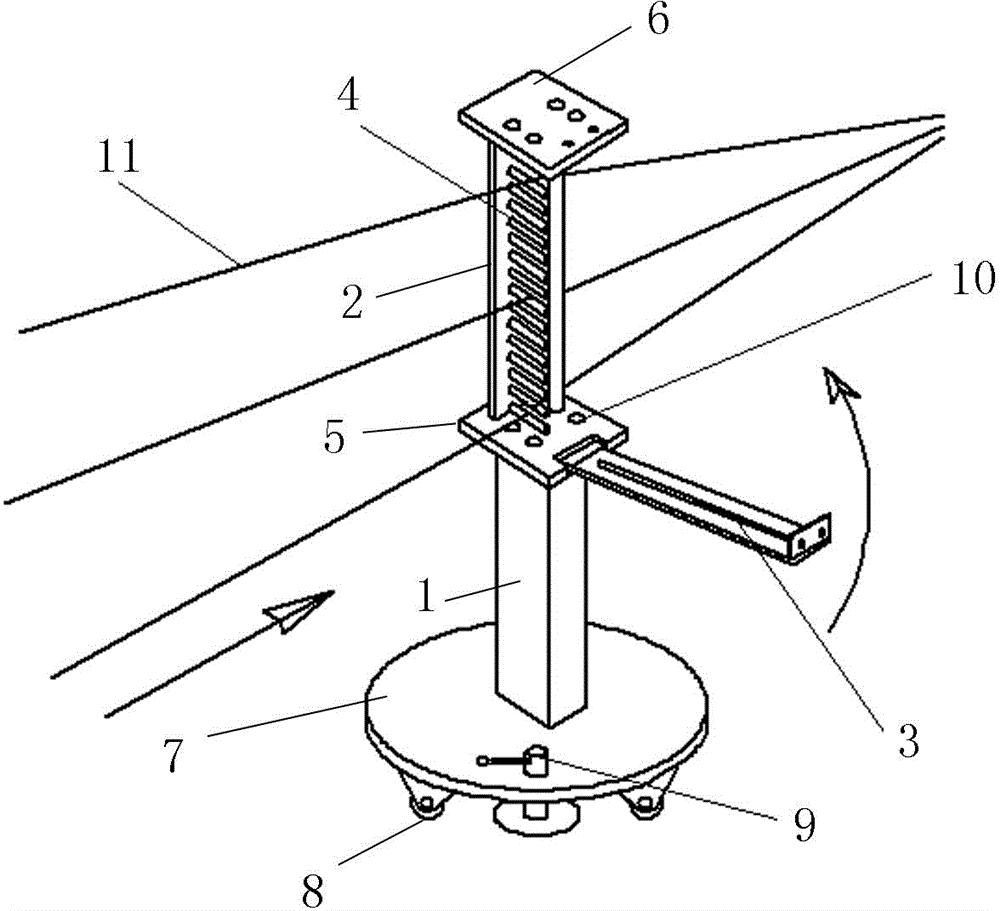

Automatic initial failure device for continuous collapse test of rectangular rod piece space structure

PendingCN111521425AInvalidEasy to makeStructural/machines measurementMagnetic tension forceStructural engineering

The invention discloses an automatic initial failure device for a continuous collapse test of a rectangular rod piece space structure. Two webs and a lower flange are cut off from the part, which is close to a to-be-damaged node, of the rectangular rod piece at the to-be-damaged node of the rectangular rod piece space structure, an initial failure device is adopted to replace the cut-off part of the rectangular rod piece, the initial failure device comprises an open rectangular pipe, a first electromagnet, a second electromagnet and a spring, the first electromagnet and the second electromagnet are matched with each other, and the open rectangular pipe is arranged between a rectangular rod piece body and an assembly type hollow hub joint and located below an upper flange of the cut-off part; the first electromagnet is arranged in an opening of the open rectangular pipe, and the second electromagnet is arranged on the lower surface of the upper flange of the cut-off part; and the springis arranged between the open rectangular pipe and the upper flange of the cut-off part. The principle that the electromagnet has strong magnetism when being powered on and loses magnetic force when being powered off is utilized, automatic failure of the junction of the rectangular rod piece and the assembly type joint is achieved, and rod piece failure, joint failure and connection failure can beeffectively simulated.

Owner:TIANJIN UNIV

Coil-winding wire carding machine

The invention relates to a coil-winding wire carding machine which comprises guide rods, rollers, a machine body, clamping plates and a positioning disk, wherein the clamping plate I and the clamping plate II are respectively arranged on two sides of a base plate of the machine body; the guide rods are arranged between the clamping plate I and the clamping plate II. During use, the clamping plates are opened, and a plurality of wires are put between every two guide rods in sequence; then the clamping plates are closed, and the positioning disk is screwed down. During coil winding, the wires flow through gaps of the rollers, so that the time and the labor are saved, and the wires cannot fall off; therefore, the problems of low winding quality of transformer coils and low construction speed are solved; the labor cost is saved, and the labor intensity is reduced.

Owner:STATE GRID CORP OF CHINA +1

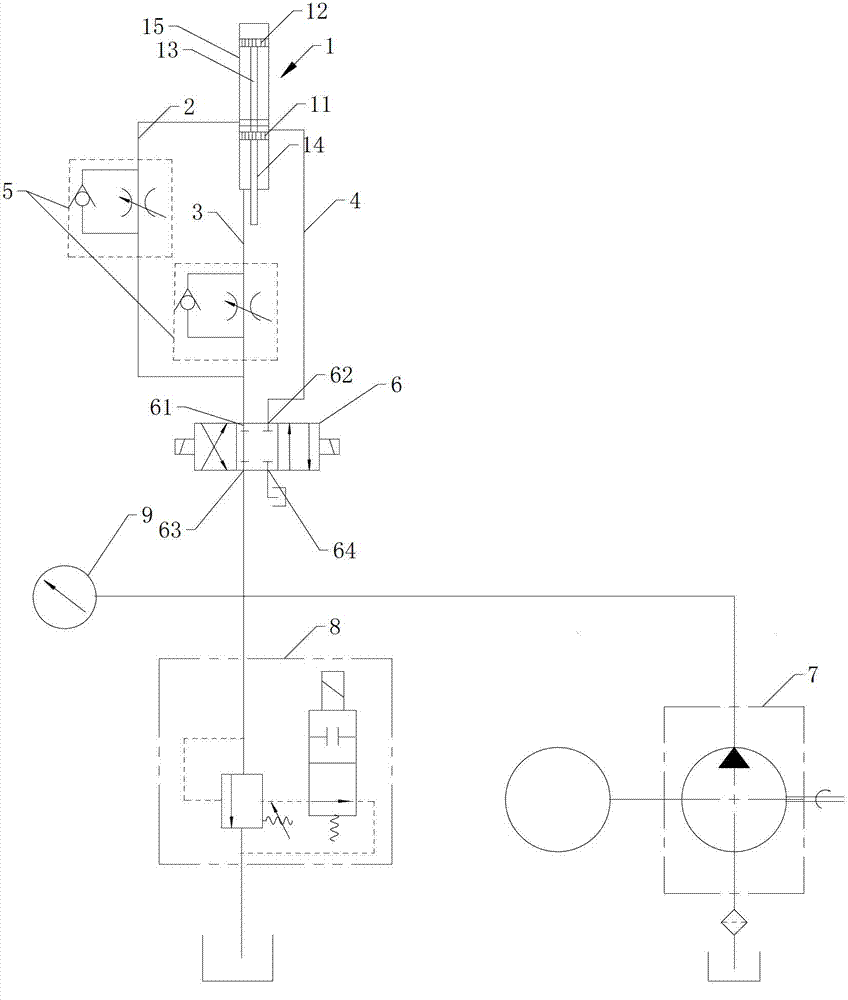

Oil circuit system of main oil cylinder of tube bending machine

The invention discloses an oil circuit system of a main oil cylinder of a tube bending machine. The oil circuit system comprises the main oil cylinder; the main oil cylinder comprises a cylinder barrel, a first piston and a second piston; the first piston and the second piston are slidably arranged in the cylinder barrel and are connected with each other through a connecting rod; and the first piston approaches the head of the main oil cylinder and is connected with a piston rod which extends out of the main oil cylinder. The oil circuit system also comprises a first contraction force application pipeline, a second contraction force application pipeline, an extension force application pipeline, an oil pump and a three-position four-way electromagnetic valve, wherein the first contraction force application pipeline is communicated with a cavity between the first piston and the second piston; the second contraction force application pipeline is communicated with a cavity between the first piston and the head of the cylinder barrel; the extension force application pipeline is communicated with the cavity between the first piston and the second piston; the oil pump is communicated with an oil supply port of the three-position four-way electromagnetic valve; both the first contraction force application pipeline and the second contraction force application pipeline are communicated with a contraction force application port of the three-position four-way electromagnetic valve; the extension force application pipeline is communicated with an extension force application port of the three-position four-way electromagnetic valve; and an overflow port of the three-position four-way electromagnetic valve is communicated with an overflow barrel. The oil circuit system of the main oil cylinder can meet requirements on tube bending force of the large tube bending machine with the oil cylinder, and is fast in bending speed, so that production efficiency is improved.

Owner:张家港市华舜机械制造有限公司

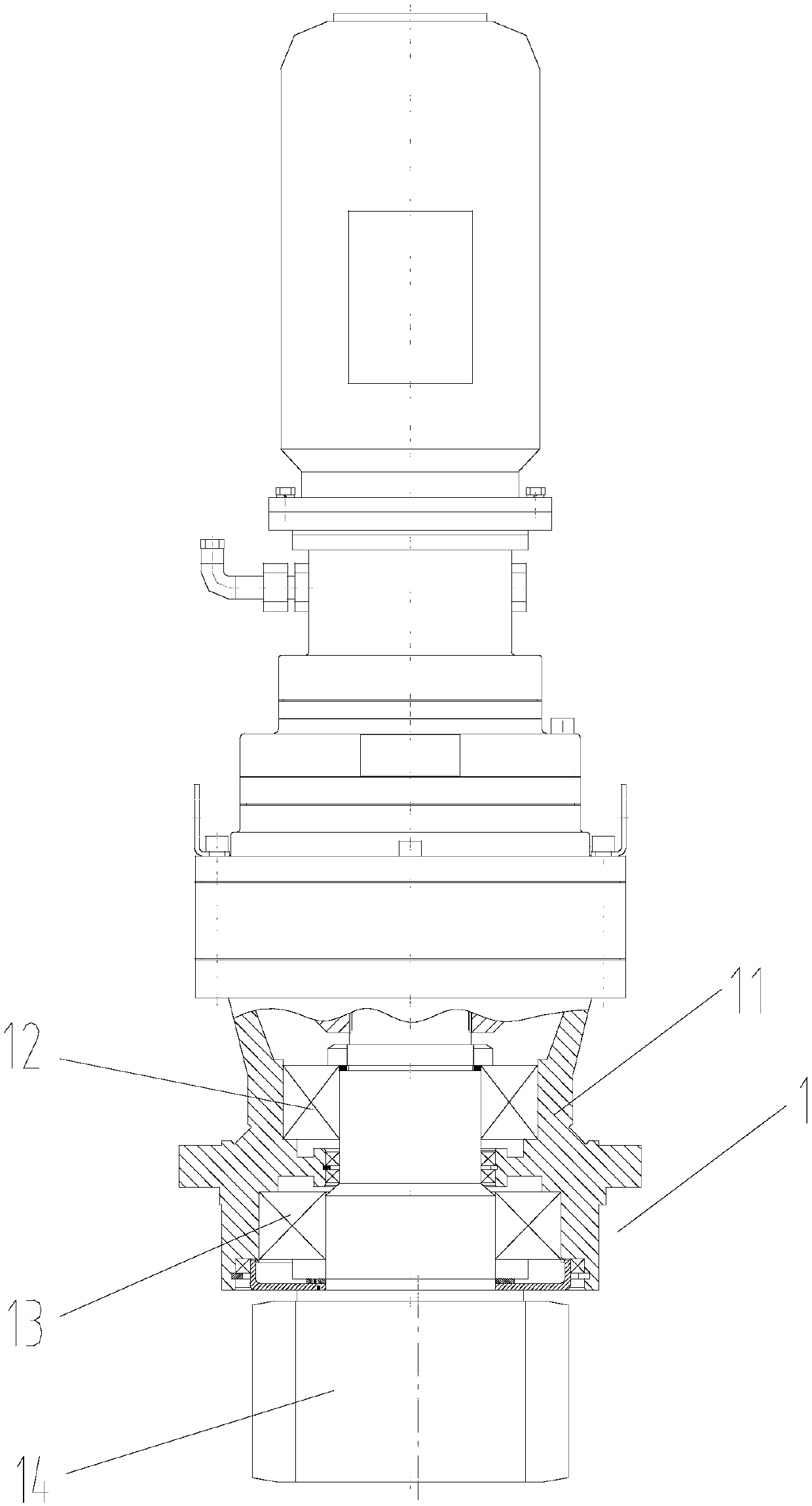

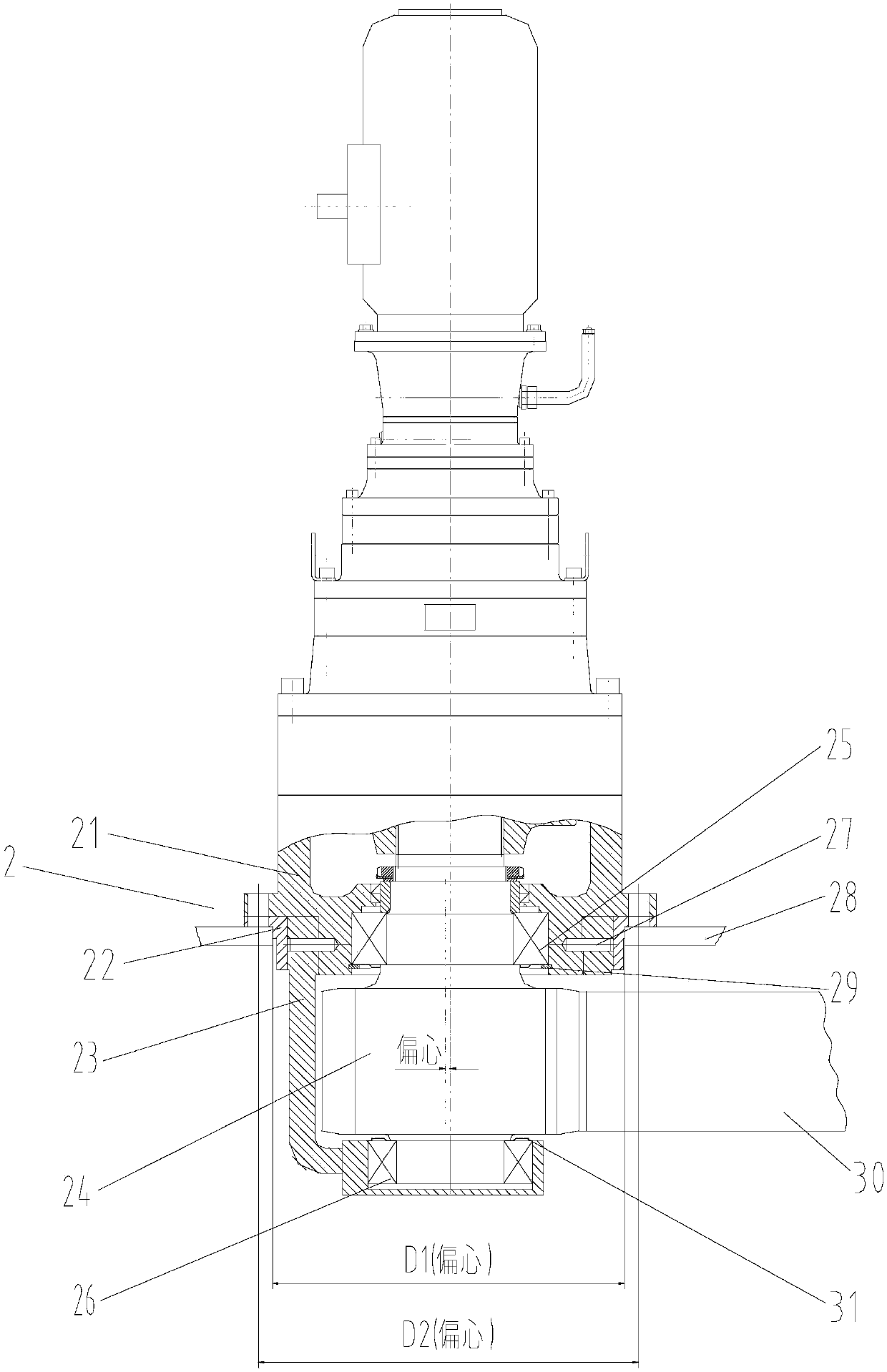

Yaw speed reducer output device

The invention provides a yaw speed reducer output device which comprises a first shell, an upper bearing installed on the first body, an output shaft gear, a half-surrounded second shell in matched connection with the first shell through a cylindrical pin, a lower bearing installed on the second shell, an eccentric ring on the outer face of the second shell, and upper and down dustproof rings forsealing lubricating grease of the upper and lower bearings. In the yaw speed reducer output device, two-end supporting is adopted for the output shaft gear, the tooth face load is uniform when an output small gear is engaged with a rotary large gear ring, and the gear strength is improved. In order to solve the problem of stress uniform load when multiple yaw speed reducers are engaged with the rotary large gear ring, the tooth side gaps of pairs of engaged teeth are ensured same, the eccentric ring is adopted for each yaw speed reducer to adjust the gear engagement center distance, namely theside gap, it is ensured that the output shaft gear is correctly engaged with the large gear ring, and the problem that the gap position of the half-surrounded second shell cannot be changed is solved. On the other hand, the second shell plays a protection role in the output small gear.

Owner:TAIYUAN HEAVY IND

An integrated power generation device of tidal current energy and vortex-induced vibration energy

ActiveCN106870269BSame forceImprove extraction efficiencyPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesVibration amplitudeWater turbine

The invention provides a tidal current energy and vortex-induced vibration energy comprehensive power generation device. The tidal current energy and vortex-induced vibration energy comprehensive power generation device comprises a tidal current energy water turbine and a vortex-induced vibration energy capturing device. A power generator, a power distribution box and a rectifying and voltage-stabilizing device which are sequentially connected with an impeller through wires are arranged in a power generator cabin of the tidal current energy water turbine. The vortex-induced vibration energy capturing device comprises a shell, a vibrator sliding along a guide rail, and a piezoelectric plate, wherein the shell is mounted on the rear side of a single pile foundation, the two end edges of the vibrator are arranged on the top surface and the bottom surface of the shell, and the two ends of the piezoelectric plate are connected with the vibrator and the rear end face of the shell correspondingly; and a conductive copper sheet is arranged at the end, connected with the rear end face of the shell, of the piezoelectric plate and sequentially connected with the rectifying and voltage-stabilizing device and the power distribution box located in the power generator cabin through wires. Water flow enters the shell after encountering the single pile foundation of the water turbine, vortexes falling alternately are generated on the two sides of the pile foundation, and vortex resonance is formed when the vortexes pass through the vibrator; and under the wake flow galloping effect, the vibration amplitude of the vibrator is greater than the vibration amplitude caused by resonance of ordinary vortexes, the vibrator drives the piezoelectric plate to swing left and right, and thus mechanical energy is converted into electric energy.

Owner:HOHAI UNIV +1

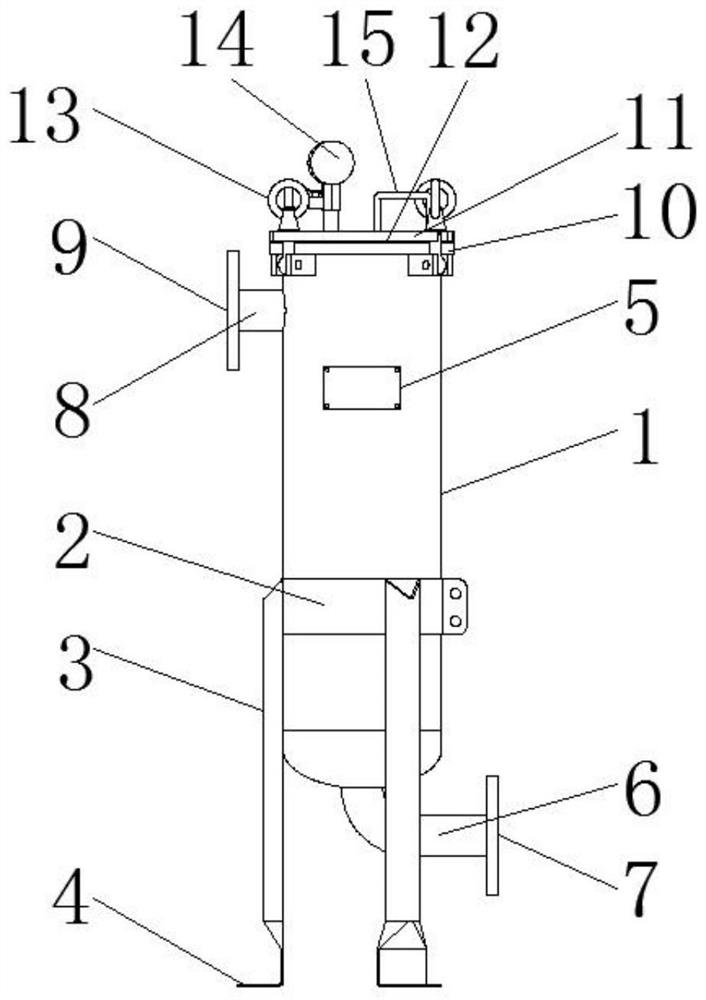

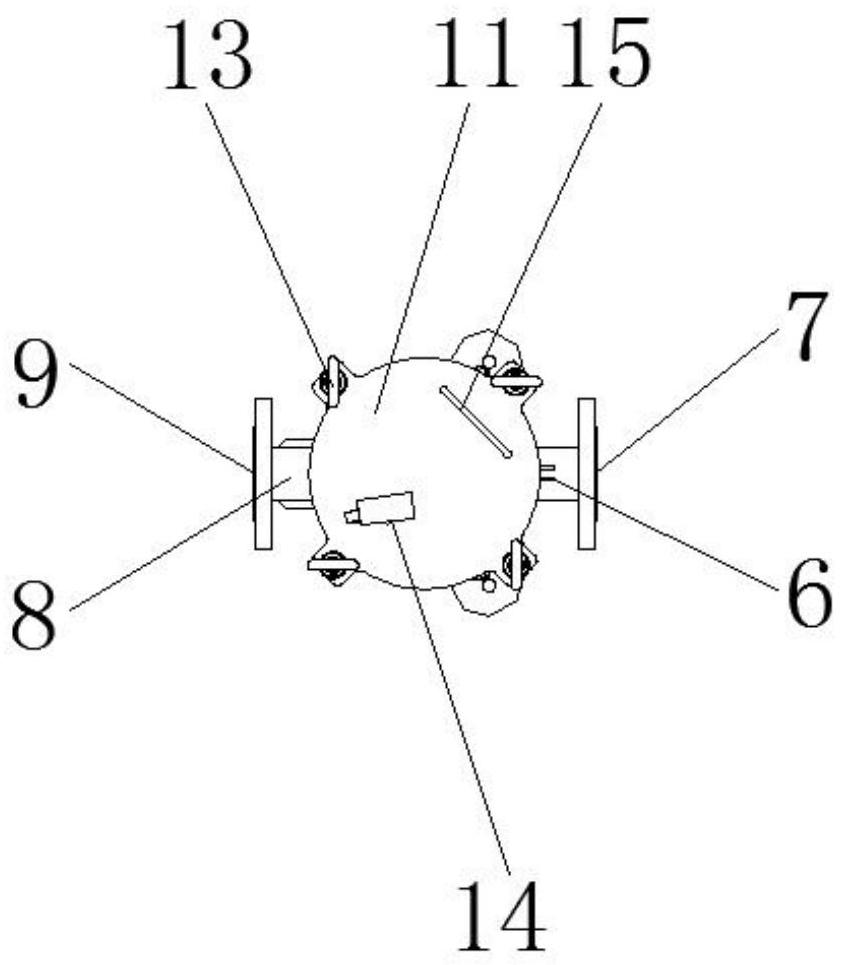

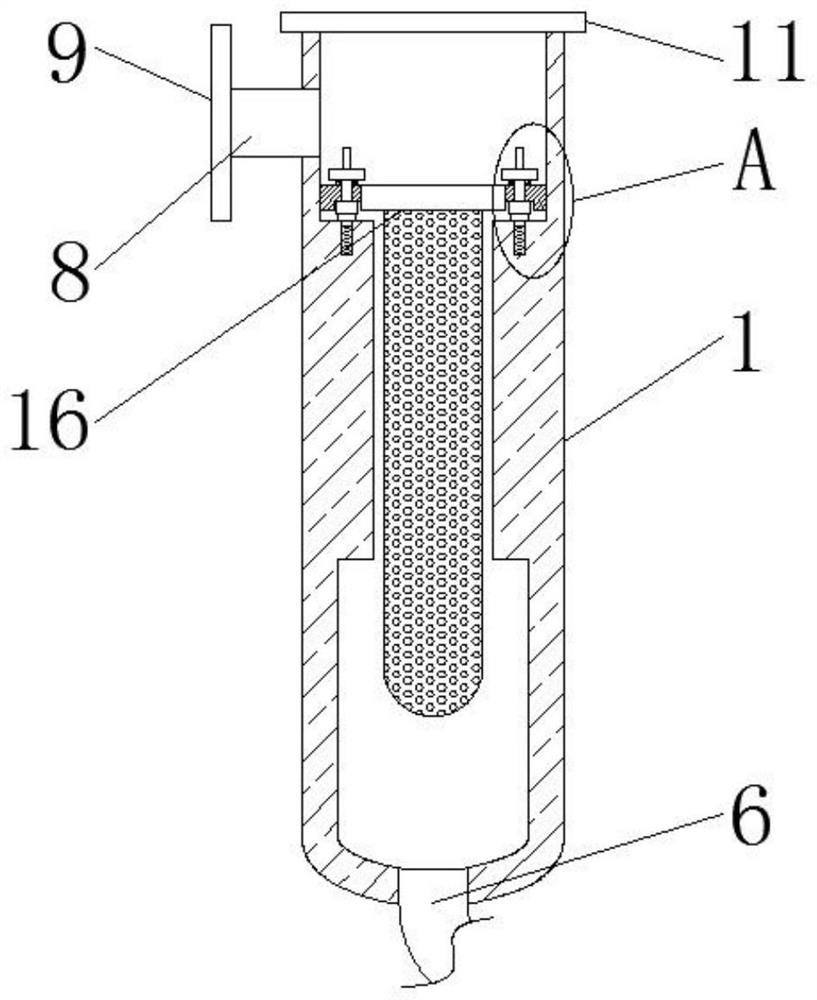

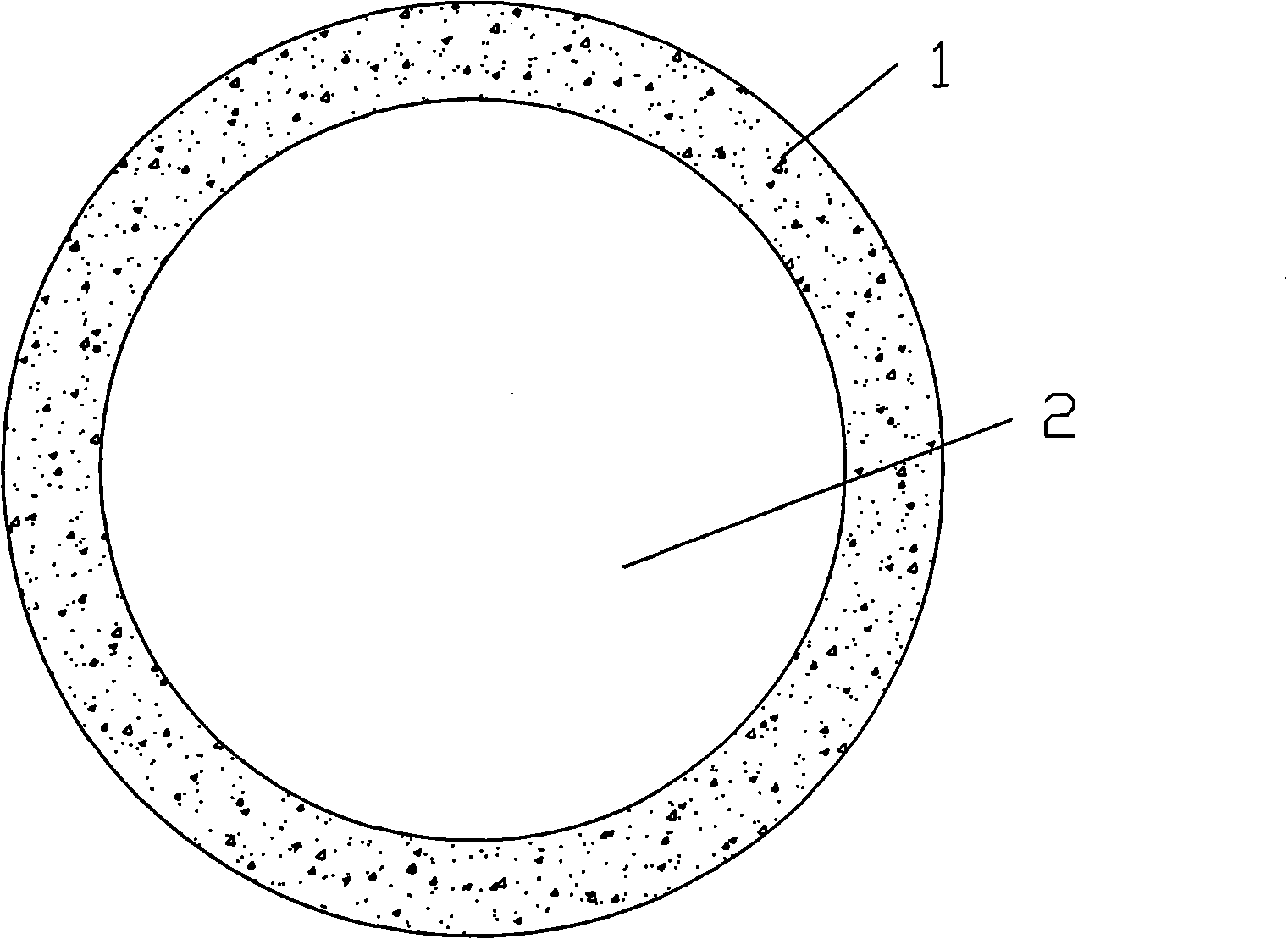

a bag filter

ActiveCN109529430BReduce impactBig impactMembrane filtersGravity filtersClassical mechanicsEngineering

The invention discloses a bag type filter, which comprises a case, wherein a filter core is arranged in the case; the filter core is fixedly arranged on the inner side wall of the case through two elastic fixing elements; the two elastic fixing elements are in left and right symmetrical arrangement; each elastic fixing element consists of a slide rod, a jacking block, a circular ring, a second soft pad, a threaded section and a buffer ring; the slide rod is arranged inside the filter core; the top end of the slide rod is provided with a jacking block; the circular ring is arranged in the middle part of the upper end of the jacking block; the second soft pad sleeves the slide rod and is arranged between the jacking block and the filter core; the lower part of the slide rod is made into a threaded section; the threaded section is arranged on the inner side wall of the case and is connected through screw threads; the buffer ring sleeves the slide rod and is arranged between the filter core and the inner side wall of the case. The filter core is fixedly installed through the elastic fixing elements; a medium can generate the impact force effect on the filter core; the elastic fixing elements can achieve the buffer effect; the impact effect of the medium is reduced; the filter core is prevented from receiving great impact force; the service life of the filter core is prolonged.

Owner:江苏亿滔环保机械有限公司

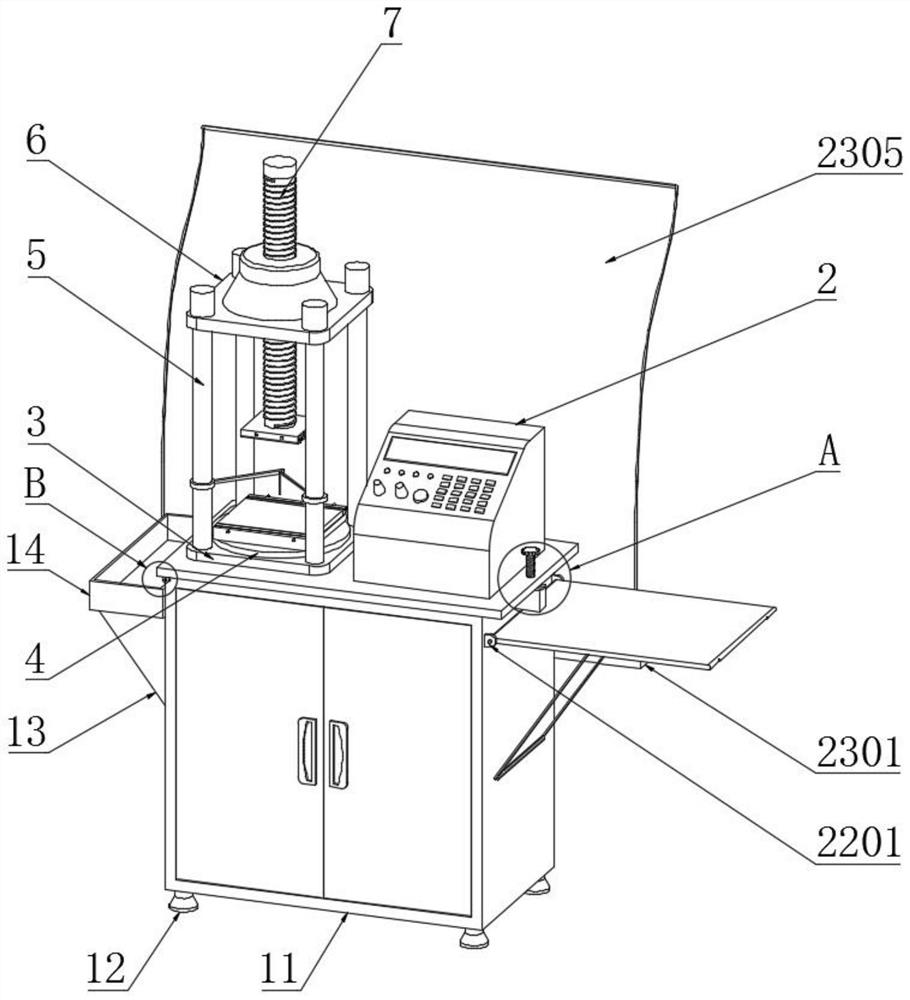

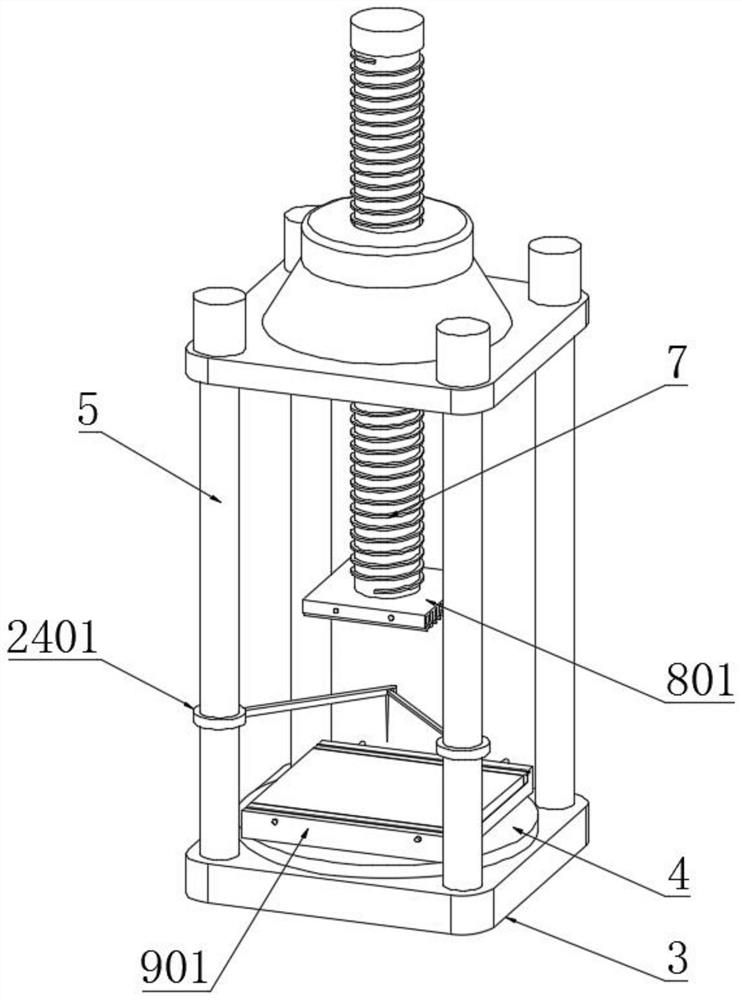

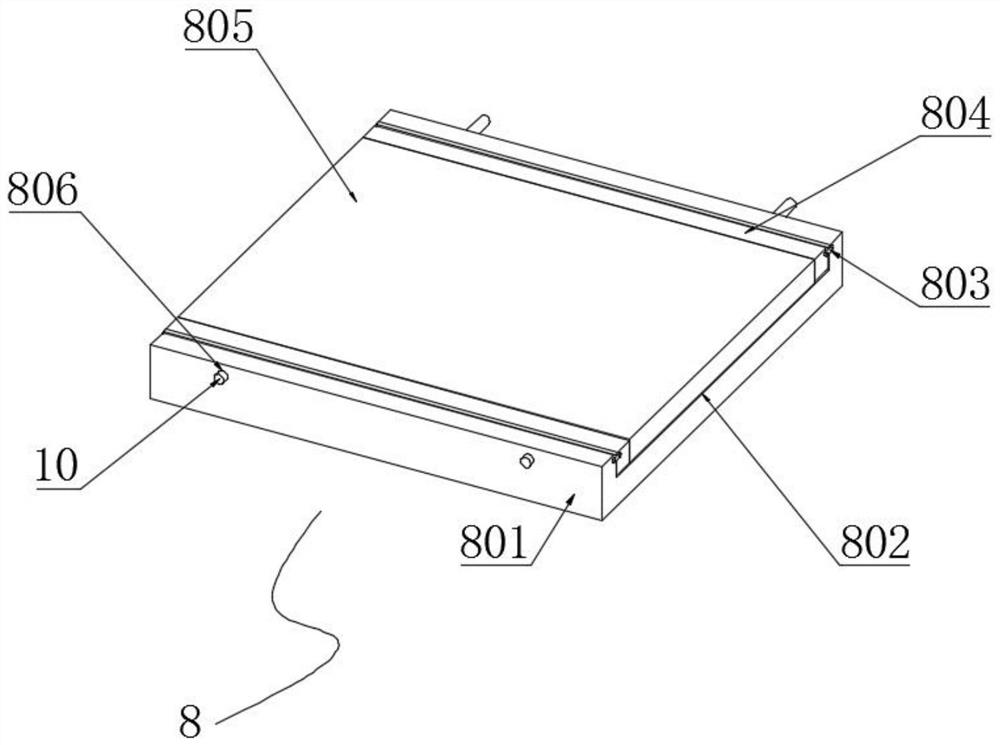

A concrete strength test device for civil construction

InactiveCN109668795BImprove accuracyFacilitate the experiment of flexural strengthMaterial strength using steady bending forcesArchitectural engineeringStructural engineering

The invention discloses a concrete strength experiment device for civil engineering construction, which comprises a workbench. A lower installation seat is installed on the other side of the top of the workbench. An induction seat is installed on the top of the lower installation seat. There is a pressure bar, the top of the induction seat is equipped with a support assembly, and the bottom end of the pressure bar is welded with a press-down assembly. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. The support assembly and the press-down assembly are provided. The overturning and the extraction of the auxiliary cushion block are convenient for the experiment of the flexural strength of the concrete block. The operation is simple and convenient, and it is convenient for the experiment to obtain more relevant data on the strength of the concrete. The position of the force on the top is changed, which is convenient for multiple experiments to find the appropriate strength value, avoids the experimental deviation caused by the single position experiment, and improves the accuracy of the experimental data.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

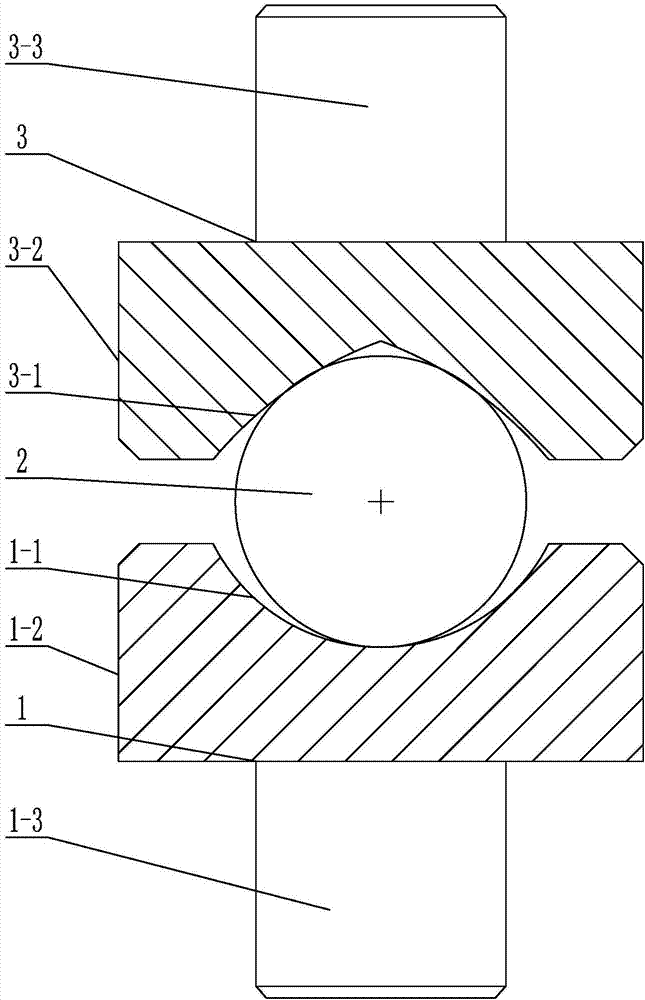

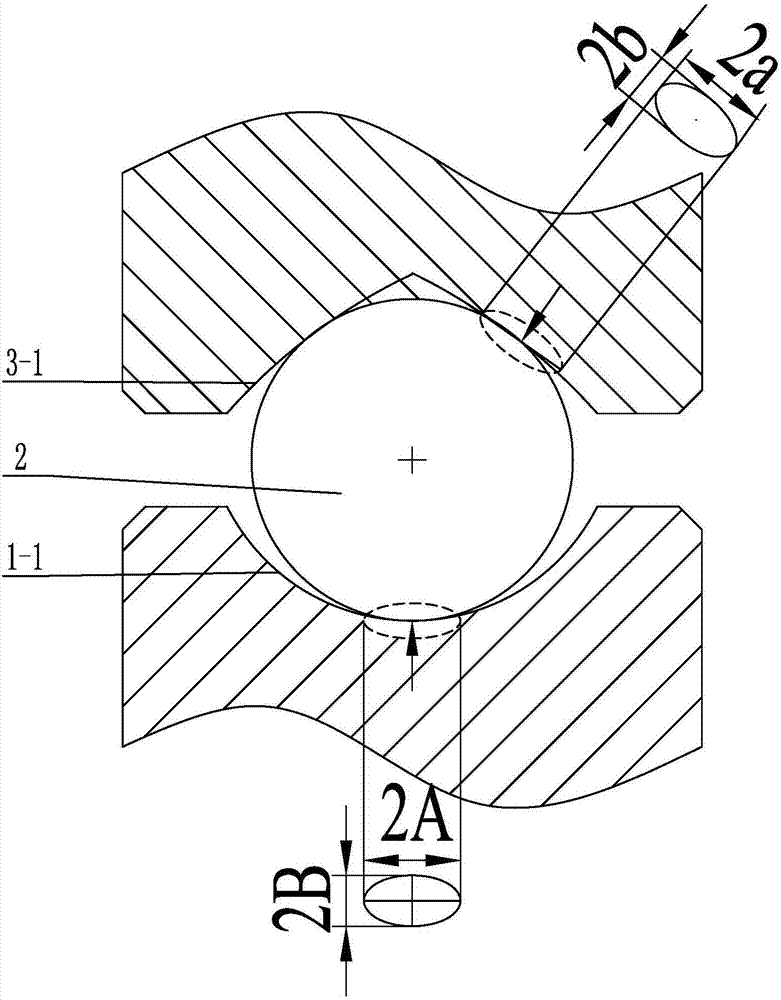

Gothic groove supporting device of mass center measurement equipment

InactiveCN107356371AReduce lateral forceHas full positioningStatic/dynamic balance measurementBiochemical engineeringMass center

The invention relates to a Gothic groove supporting device of mass center measurement equipment, relates to the measurement technology field and solves a problem of influence on measurement accuracy caused by poor stability of a supporting device of mass center measurement equipment in the prior art. The Gothic groove supporting device comprises a lower supporting body, a ball body and an upper supporting board which are sequentially arranged from up to down, the middle portion of an upper end surface of the lower supporting body is provided with a spherical groove, the middle portion of a lower end surface of the upper supporting body is provided with a groove in the horizontal direction, the groove bottom of the groove is a tip end, two side groove walls of the groove are arc-shaped structures, and the ball body is arranged between the spherical groove and the groove. The Gothic groove supporting device is applicable to object mass center measurement.

Owner:HARBIN INST OF TECH

A constant velocity universal joint bell-shaped shell inner support fixture

The invention provides an inner-supporting clamp of a constant-velocity universal joint bell housing, which is mainly applied to the machining field of the constant-velocity universal joint bell housing. The inner-supporting clamp comprises a clamp body, wherein a top block is arranged on the side part at the front end of the clamp body; and an ejecting structure for ejecting the top block is arranged on the clamp body. The inner-supporting clamp of the constant-velocity universal joint bell housing can be used for clamping the constant-velocity universal joint bell housing by one step, and simultaneously completing rough-finish turning machining of the outer diameter and the end surface of the bell housing, so that secondary clamping error risks are removed and the time consumption for disassembling the clamped workpiece is reduced. Besides, the inner-supporting clamp of the constant-velocity universal joint bell housing has the advantages of being high in machining product precision, small in labor intensity and high in production efficiency.

Owner:ZHEJIANG ODM TRANSMISSION TECH

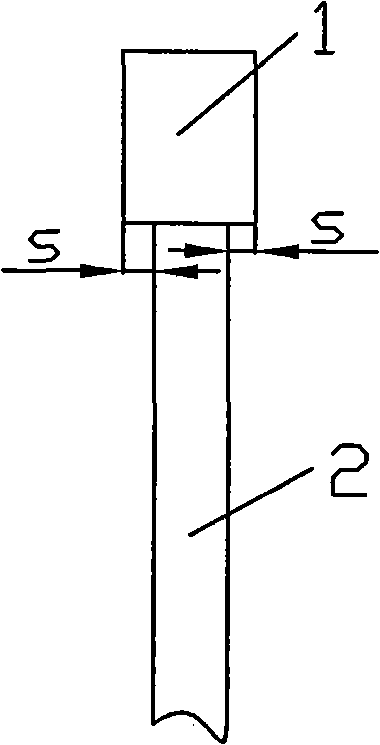

Method for producing diamond saw bit special for glass-cutting

InactiveCN101289273ASolve the lack of hardnessSmall flatness errorGlass severing apparatusSheet steelHardness

The invention discloses a method for producing a diamond saw blade specially used in glass cutting. A 65Mn steel plate is first stamped into a disc-shaped substrate and then placed in a sintering furnace to be heated to 850 DEG C and the temperature is maintained for more than 6 hours; after the substrate is cooled in an air-cooling method, a grinder is used for grinding both sides of the substrate; the error of the flatness of the substrate is guaranteed to be less than 0.3mm; after that, the cold pressing of diamond and a binder is carried out on the substrate with the pressure of the cold pressing of 16kg; a hot pressed stainless steel mold is then used for sintering the substrate and a blade body so as to ensure that the width S of steps at both sides of the blade body is the same; the sintering temperature reaches 780 DEG C and the time for keeping the temperature is not less than 8 hours; painting and edging are finally followed. The method of the invention adopts the heat treatment to ensure that the hardness of the substrate can achieve Rockwell hardness of above 48; the substrate after the heat treatment is ground to guarantee the flatness of both sides of the substrate, the horizontal vibration during the glass cutting is reduced; in addition, the pressure of the cold pressing of the substrate and the binder is improved, which results in the uniform force bearing of both sides of the blade body when cutting and a neat and straight cutting slot.

Owner:江苏益林金刚石工具有限公司 +1

Manufacturing device and method of vibration measuring tube

The invention discloses a manufacturing device of a vibration measuring tube. The manufacturing device comprises an upper mold and a lower mold. The middle portion of the lower mold is provided with asunken part capable of allowing the lower portion of the upper mold to be inserted in, and the lower portion of the upper mold is provided with a protrusion capable of being inserted into the sunkenpart. The lower portion of the upper mold is provided with an upper mold pressing groove used for cold-pressing the vibration measuring tube. The lower mold is provided with a lower mold pressing groove corresponding to the upper mold. The two sides of the sunken part of the lower mold are provided with roller molds capable of reducing friction force between the vibration measuring tube and the lower mold. The axes of the roller molds are perpendicular to the center line of the lower mold pressing groove. Each roller mold is provided with a circle of roller pressing groove. The invention further provides a manufacturing method of the vibration measuring tube. The manufacturing method comprises the steps of S1, feeding a vibration measuring tube blank into the lower mold pressing groove inthe upper surface of the lower mold, and driving the upper mold to move downwards to start to conduct cold-pressing; and S2, eliminating deformation generated in the cold-pressing process through a water expansion process. Through the manufacturing device and method of the vibration measuring tube, provided by the invention, the manufacturing precision of the vibration measuring tube can be improved.

Owner:ZHEJIANG SUPCON INSTR

Adjustable clothing tailoring discharging tensioning structure

ActiveCN112538745AAchieve tensionAdjustable tensionSevering textilesClassical mechanicsStructural engineering

The invention belongs to the technical field of clothing tailoring, and particularly relates to an adjustable clothing tailoring discharging tensioning structure. The adjustable clothing tailoring discharging tensioning structure comprises a workbench, supporting plates, a cover plate and a tensioning mechanism. The supporting plates are symmetrically arranged at the top of the workbench and fixedly connected with the top of the workbench; the cover plate is fixedly connected to the tops of the supporting plates; the tensioning mechanism is arranged at the top of the workbench; the tensioningmechanism comprises an air cylinder, a first push rod, a first push plate, sliding grooves, a first piston cylinder, a rectangular shell, a second push rod, a connecting rod, a first rectangular blockand a suction cup; the air cylinder is fixedly connected to the top of the cover plate; the first push rod is fixedly connected to a piston rod at the bottom of the air cylinder; the first push plateis fixedly connected to the bottom of the first push rod, and the first push plate is slidably connected with the side walls of the supporting plates; the sliding grooves are symmetrically formed inthe top of the first push plate; the first piston cylinder is connected into the sliding grooves in a sliding mode; and the rectangular shell is fixedly connected to the side wall of the first pistoncylinder. Tensioning of cloth is realized.

Owner:浦江县伊路维尼服装有限公司

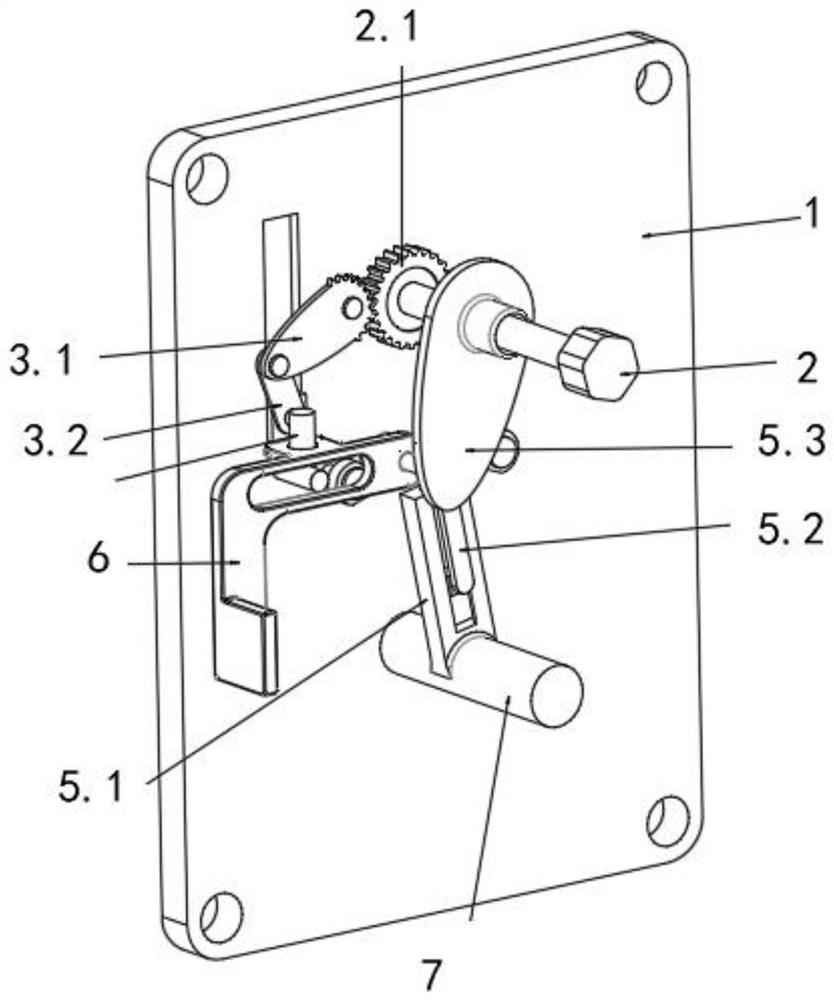

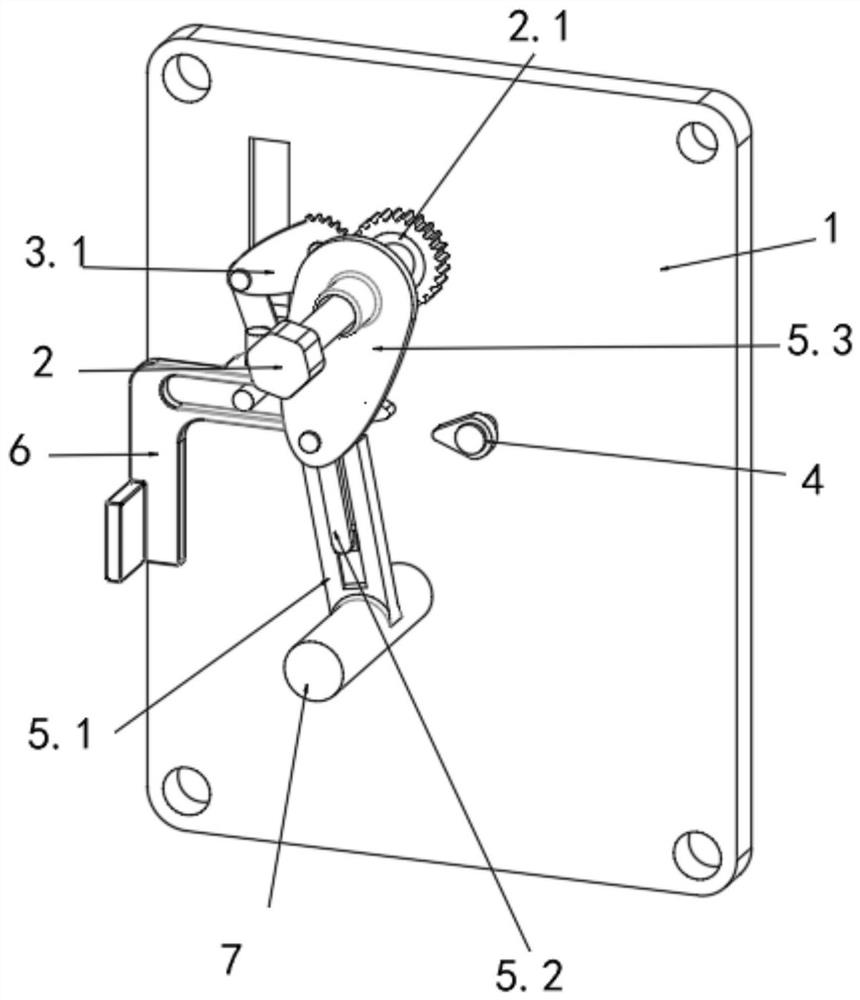

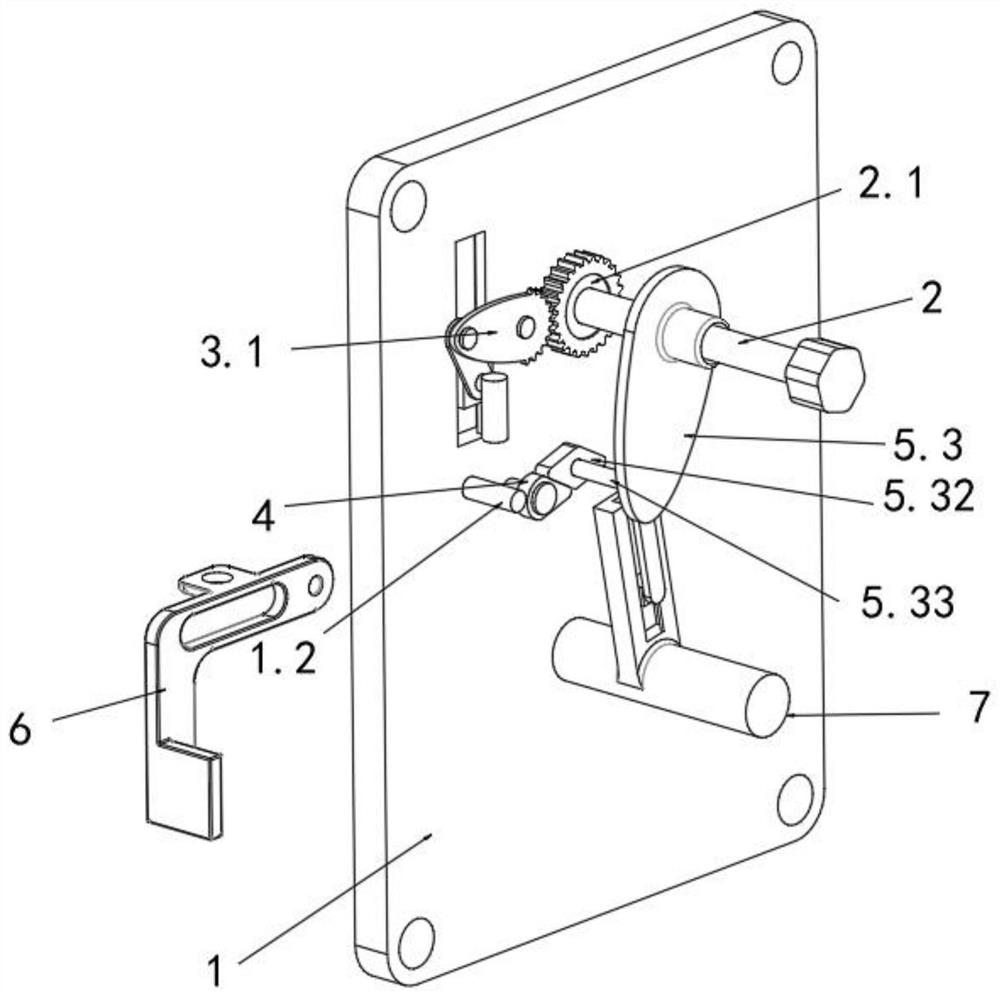

Isolation switch triggering mechanism

The invention discloses an isolation switch triggering mechanism, and relates to the field of isolation switches. The isolation switch triggering mechanism comprises: a bottom plate, wherein a rotating shaft and an operating shaft for opening and closing an isolation switch are arranged on the bottom plate, and a triggering mechanism is connected between the rotating shaft and the operating shaft, and is provided with a first position corresponding to the open state of the operating shaft and a second position corresponding to the closed state of the operating shaft; and two force application assemblies arranged on the two opposite sides of the bottom plate respectively, wherein each force application assembly comprises an elastic reset piece and a force application piece which are connected, the triggering mechanism enters and breaks away from the first position to extrude one force application assembly, and the triggering mechanism enters and breaks away from the second position to extrude the other force application assembly. When the operating shaft is opened or closed, the force application assembly supports the triggering mechanism, the operating shaft is in a closed or opened state, and it is guaranteed that the acting force needed in the whole operation process of rotating the operating shaft is the same.

Owner:安徽新高电气有限公司

Embedded channel positioning device for subway segments and method for applying embedded channel positioning device

PendingCN109578072ASimple structureEasy to installMining devicesUnderground chambersRebarScrew thread

The invention discloses an embedded channel positioning device for subway segments and a method for applying the embedded channel positioning device. The embedded channel positioning device comprisesa first connecting rod, a rotary sleeve and a second connecting rod. The top of the first connecting rod can be detachably connected with a reinforcement cage; the rotary sleeve comprises a rotary shaft, a first sleeve and a second sleeve, the first sleeve is rotationally connected to the top of the rotary shaft, the second sleeve is rotationally connected to a rotation bottom, and the bottom of the first connecting rod is in screw thread fit with the first sleeve; the bottom of the second connecting rod is fixedly connected to an embedded channel, and the top of the second connecting rod is in screw thread fit with the second sleeve. The method includes tightening and matching the first connecting rod and the first sleeve with each other and tightening and matching the second connecting rod and the second sleeve with each other; hoisting the embedded channel positioning device and the embedded channel to predetermined locations in subway segment pouring molds; connecting the first connecting rod and the reinforcement cage with each other; loosening the first connecting rod and the first sleeve until the bottom surface of the embedded channel tightly clings to the inner bottom surfaces of the molds so as to completely position the embedded channel. The embedded channel positioning device and the method have the advantages that the embedded channel positioning device is simple in structure, good positioning effects can be realized, and the integrity of the embedded channel can be guaranteed.

Owner:HUAQIAO UNIVERSITY +1

A Method of Improving the Life of Turbine Blades Based on Laser Double-side Shock Technology

ActiveCN104862468BHighlight substantive featuresSignificant progressBlade accessoriesMachines/enginesHigh energyTurbine blade

The invention relates to a method for improving the service life of turbine blades based on laser double-sided shock technology. Firstly, Nd:YAG pulsed lasers are used to perform equal-energy laser beam splitting; then, using flowing water as a constrained layer, the blades are impacted and strengthened at the same time by using gradient facula overlapping ratios. At the root, the fixture fixes the turbine blade, using high-energy and large-spot pulsed laser with a 90% overlap rate to impact the bottom of the blade root on both sides at the same time; The lap rate of the previous impact minus 10% is used for impacting; until the lap rate is 0, the laser shock strengthening of the blade root is completed. It makes up for the shortcomings of insufficient impact depth of mechanical shot peening, and adopts a gradual lapping rate to impact the root of the blade to make the distribution of the residual stress field smoother; adopts the laser double-sided impact method to avoid deformation and damage of the blade caused by single-sided laser impact. Simultaneous impact makes the front and back of the blade bear the same force.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com