Inner-supporting clamp of constant-velocity universal joint bell housing

A technology of constant velocity universal joints and internal support fixtures, which is applied in the direction of expanding the mandrel, etc., can solve the problem of low reliability of clamping bell-shaped shell machining accuracy, non-uniform bell-shaped shell machining and positioning reference, and secondary clamping accuracy Error and other problems, to reduce the risk of large processing jump, high work intensity, and reduce the effect of relative motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

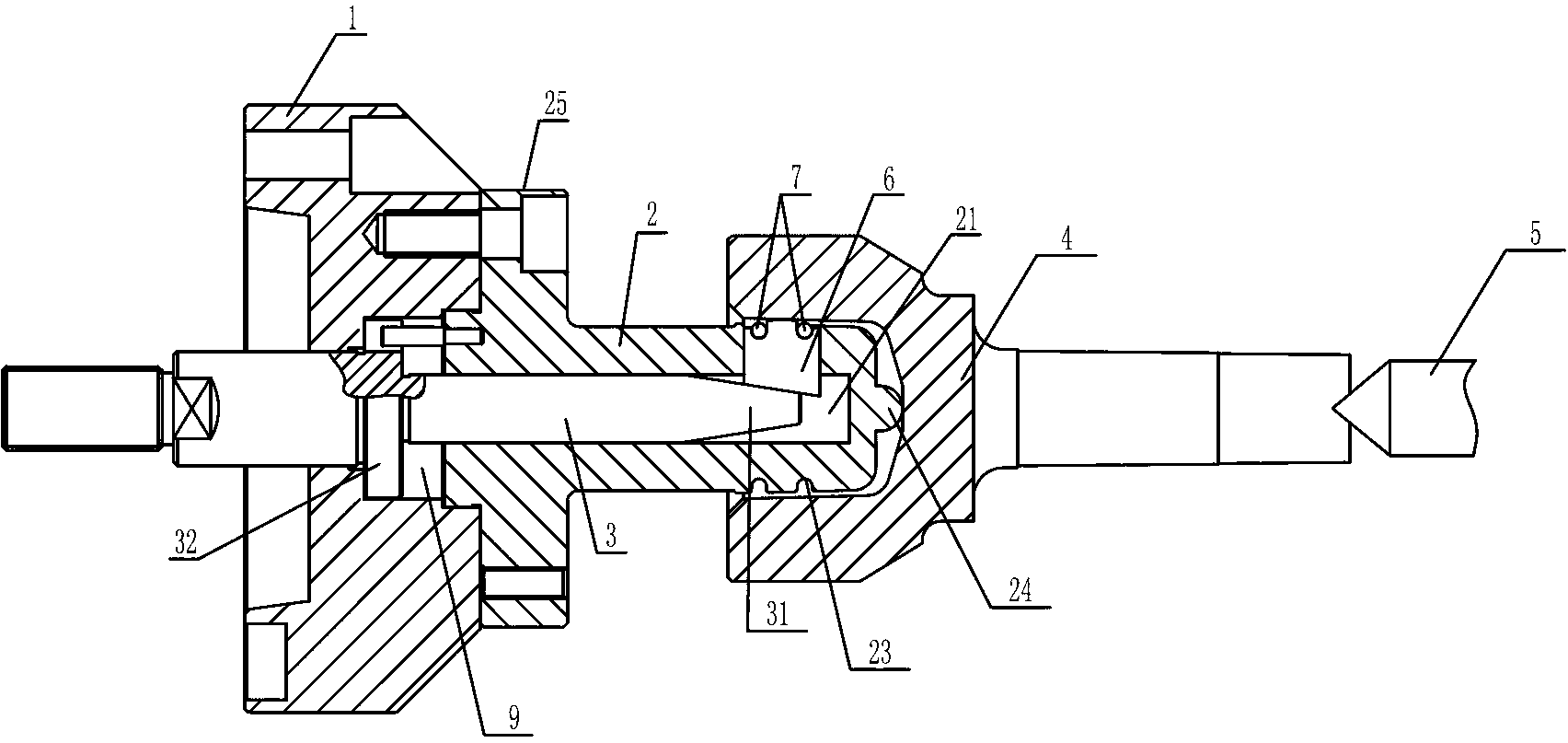

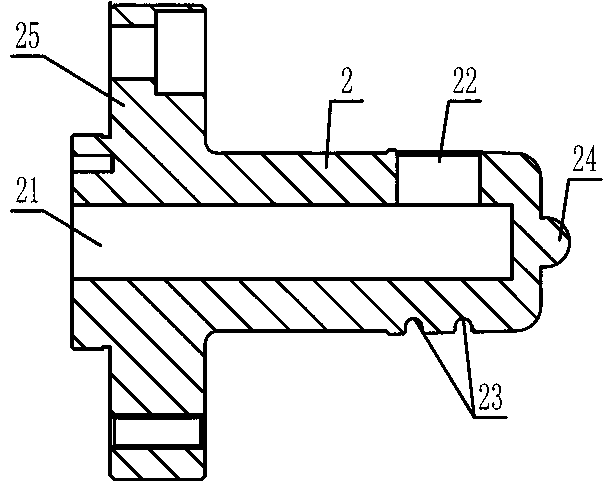

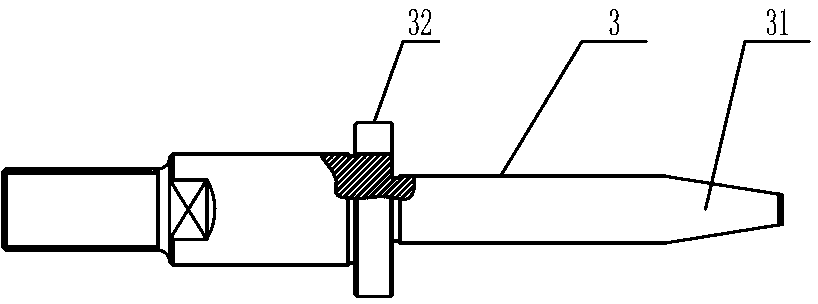

[0032] Such as Figures 1 to 5 As shown, a constant velocity universal joint bell-shaped shell internal support fixture includes a fixture main body 2, a top block 6 is provided on the front end side of the fixture main body 2, and a top block 6 is provided on the fixture main body 2. ejection structure. The end surface of the ejected end of the top block 6 is preferably a curved surface or a spherical surface.

[0033] The fixture main body 2 is provided with a groove I21 with an opening located at the tail end of the fixture main body 2, and the side of the fixture main body 2 is provided with a through hole I22 passing through the inner wall of the groove I21 and the outer wall of the fixture main body 2, and the top block 6 is set in the through hole I22, and the ejection structure is a mandrel rod 3 extending from the mouth of the groove I21 into the groove I21 to push out the top block 6. The top block 6 and the core One end of the shaft pull rod 3 is an inclined surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com