Oil circuit system of main oil cylinder of tube bending machine

A technology of oil circuit system and main oil cylinder, which is applied in mechanical equipment, fluid pressure actuating device, servo motor, etc., can solve the problems of restricting machine production efficiency, bulky whole machine, slow bending speed, etc. , The effect of small force area and accelerated bending speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific examples.

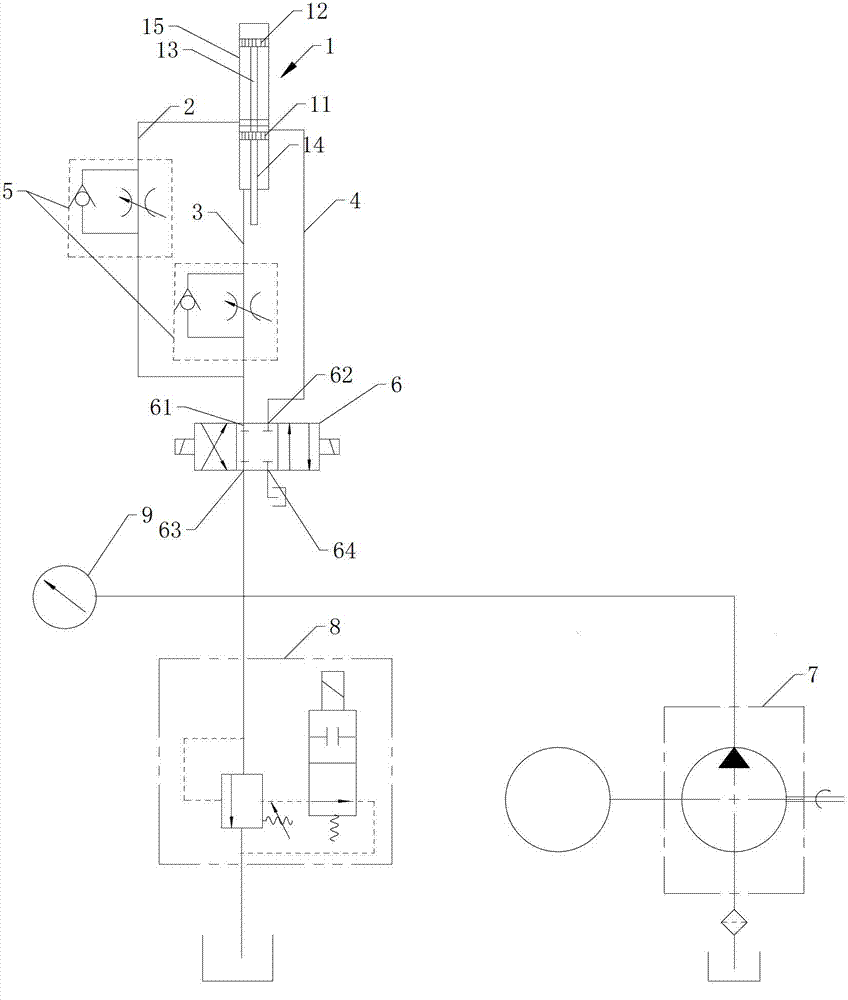

[0014] Such as figure 1 As shown, a pipe bending machine main cylinder oil circuit system includes a main cylinder 1, the main cylinder 1 includes a cylinder 15 and a first piston 11 and a second piston 12 slidingly installed in the cylinder 15, the first piston 11 and the second piston 12 are connected by a connecting rod 13, the first piston 11 and the second piston 12 act as a whole, the first piston 11 is close to the head of the master cylinder 1, and the first piston 11 is connected with a The piston rod 14; the oil circuit system of the master cylinder 1 also includes the first contraction application pipeline 2 communicating with the chamber between the first piston 11 and the second piston 12, and the first piston 11 and the cylinder barrel 15 The second contraction application line 3 communicated with the chamber between the heads, communicates with the chamber betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com