Isolation type middle-high voltage fireproof cable

A fireproof cable, medium and high voltage technology, applied in the direction of insulated cable, power cable, power cable with shielding layer/conductive layer, etc., can solve the problem of difficult bending of inorganic flame-retardant cables, achieve small bending force, avoid lightning strikes Wear, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

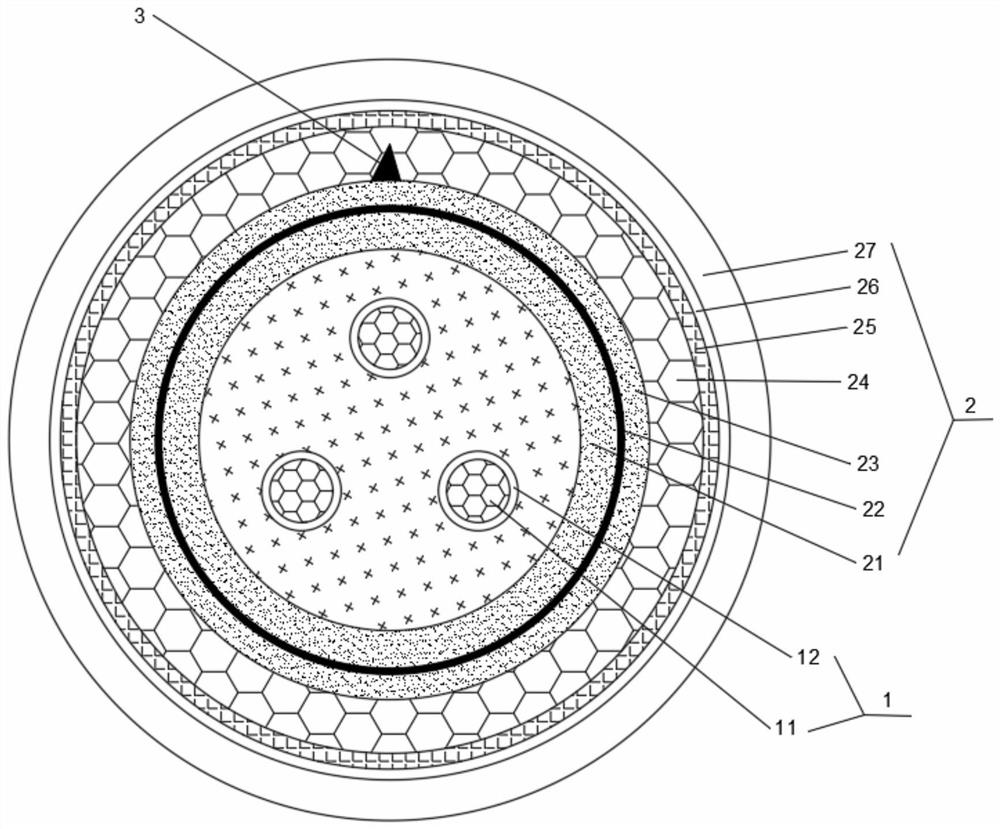

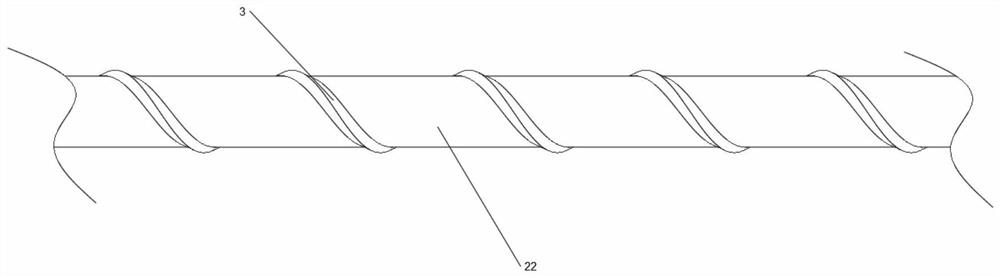

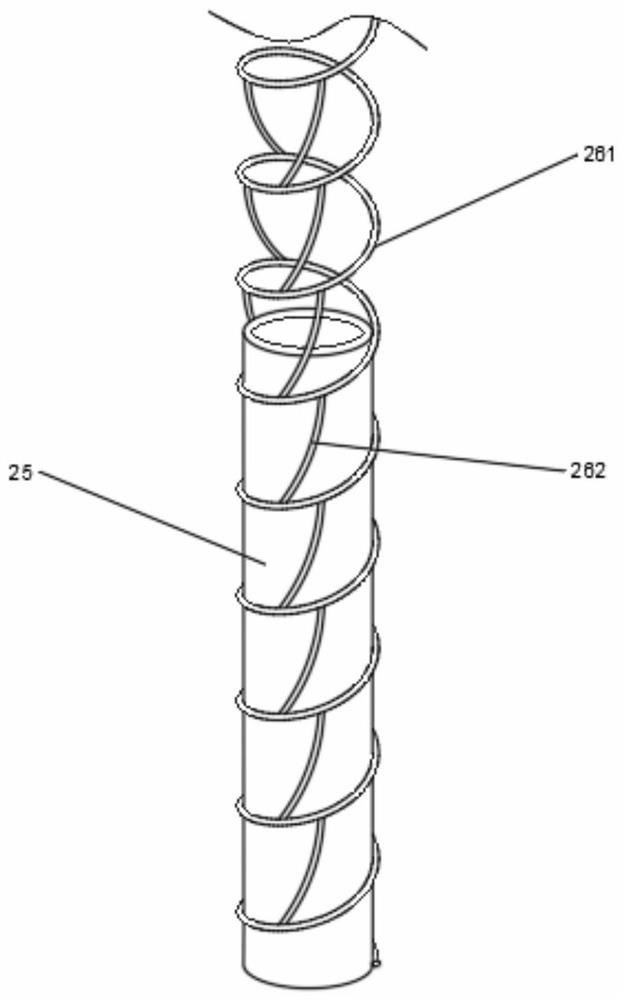

[0029] see Figure 1-3 , an isolated medium and high voltage fireproof cable in this embodiment, comprising a cable core 1 and a protective jacket, the cable core 1 is arranged in the protective jacket, and the protective jacket includes a first insulating layer 21, a metal shielding layer from the inside to the outside 22. The second insulating layer 23, the flame-retardant layer 24, the corrosion-resistant layer 25 and the outer protective layer 27. The flame-retardant layer 24 is formed at intervals between the outer surface of the second insulating layer 23 and the inner surface of the corrosion-resistant layer 25, so The flame retardant layer 24 is filled with flame retardant particles, and the outer surface of the second insulating layer 23 is provided with protruding ribs 3 , and the protruding ribs 3 are spirally arranged.

[0030] There is a distance H between the side of the protruding ribs 3 away from the second insulating layer 23 and the corrosion-resistant layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com