Recoverable lithium ion battery with high expansion rate

A lithium-ion battery with a high expansion rate technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve problems such as fan-shaped deformation, power supply capacity drop, tab or jumper breakage, etc., to prevent being pulled breakage, reduced performance, and small bending force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

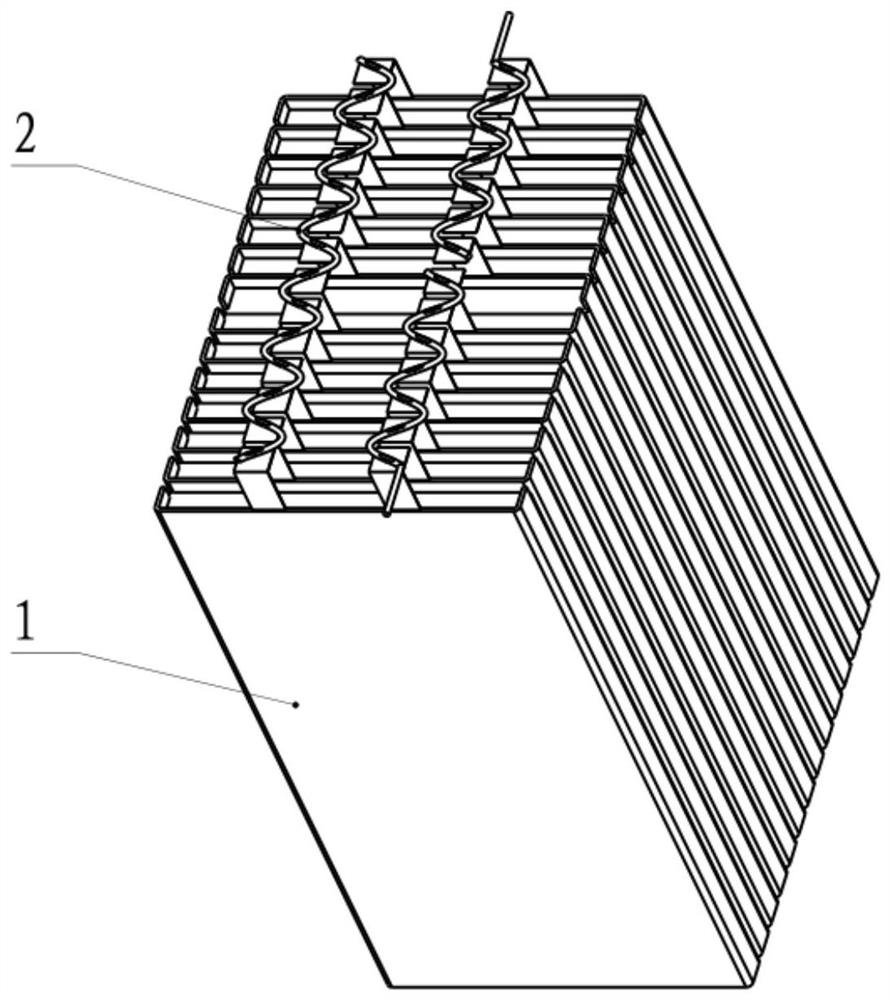

[0024] The invention provides a recoverable lithium-ion battery with high expansion rate, which includes several lithium-ion battery cells 1 and conductive wires 2, two or more lithium-ion battery cells are combined in a stacked manner, The batteries are electrically connected to form a parallel block, and at the same time the parallel block can be connected in series.

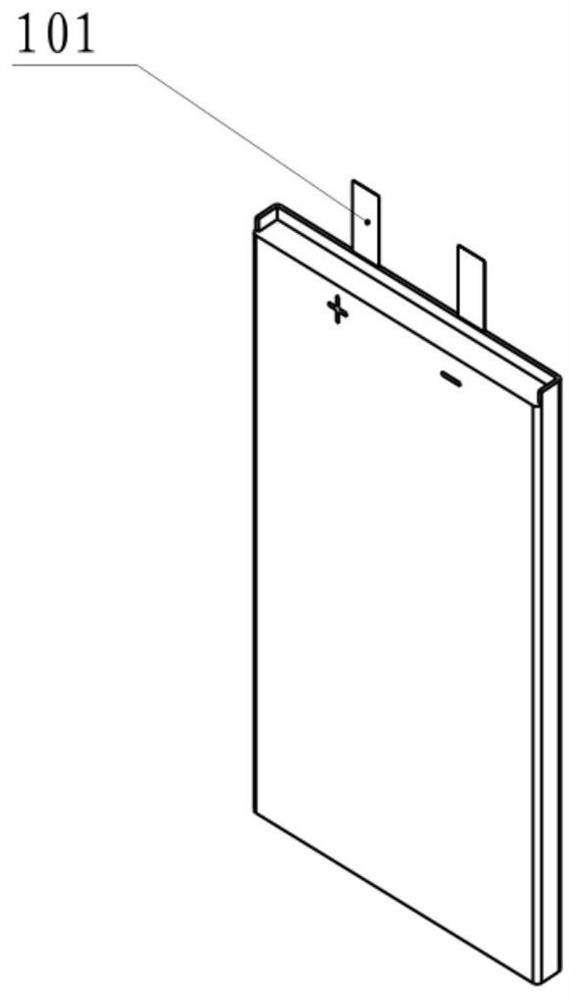

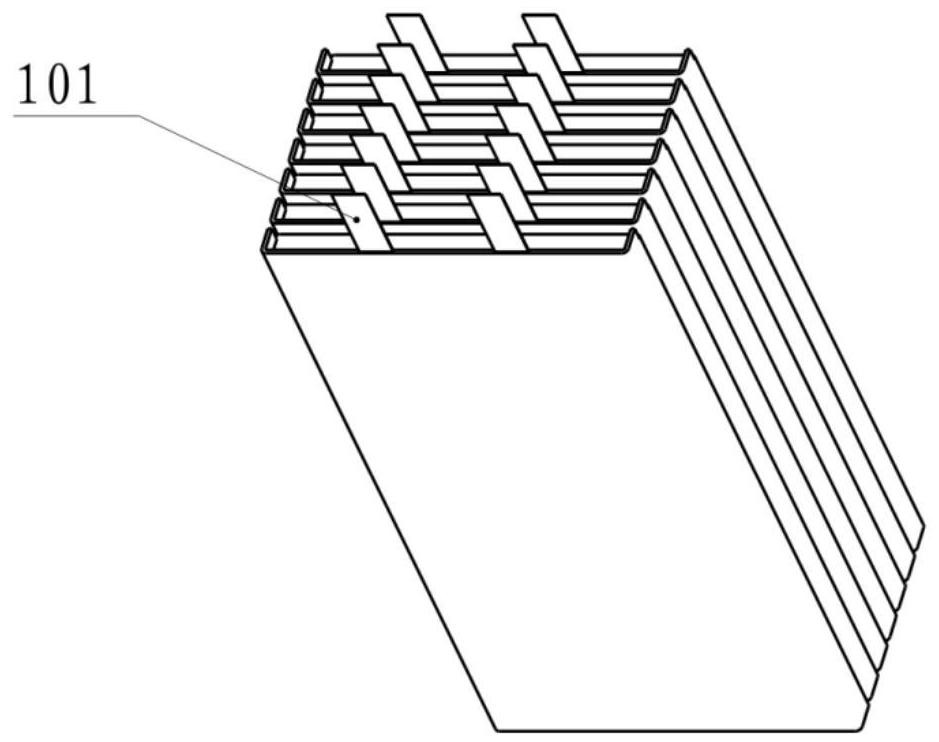

[0025] Wherein, the tab of the lithium-ion single battery is a tab 101 in a straight state before bending, such as figure 2 Shown; stack multiple Li-ion cells into required arrays, such as image 3 As shown; all the conductive tabs of the lithium-ion single battery array are bent into a "7" shape, and at this time, the "7"-shaped conductive tabs 102 are obtained,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com