Method for producing diamond saw bit special for glass-cutting

A technology of diamond saw blades and production methods, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of insufficient hardness of the matrix, reduce the lateral vibration of cut glass, and increase the holding force of the carcass.

Inactive Publication Date: 2008-10-22

江苏益林金刚石工具有限公司 +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

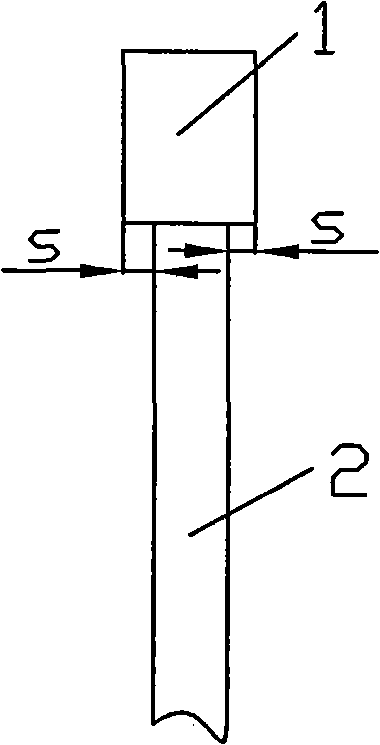

The invention adopts heat treatment process to solve the problem of insufficient matrix hardness; the hardness of the matrix can reach more than 48 Rockwell hardness; the heat-treated matrix is ground to ensure that the flatness error on both sides of the matrix is less than 0.3mm, and reduce the lateral vibration when cutting glass ; Increase the cold pressure of the matrix and the binder, thereby increasing the density of the matrix and increasing the holding force of the matrix to the matrix; sintering with a hot-pressed stainless steel mold to ensure that the width of the steps on both sides of the diamond saw blade body is the same, so that the diamond When the saw blade cuts glass, both sides of the knife body are evenly stressed to ensure that the cutting seam is smooth and straight

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

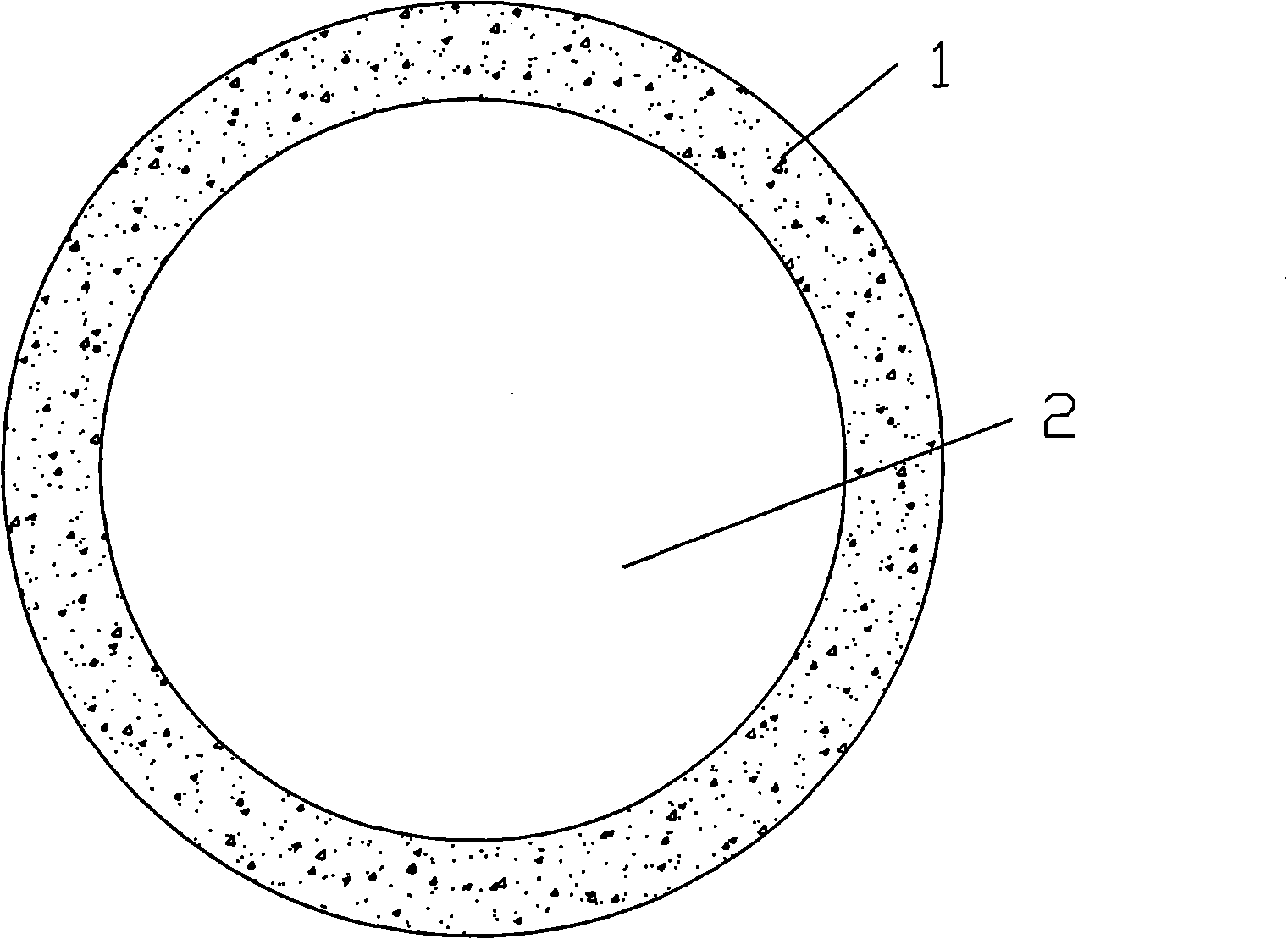

The invention discloses a method for producing a diamond saw blade specially used in glass cutting. A 65Mn steel plate is first stamped into a disc-shaped substrate and then placed in a sintering furnace to be heated to 850 DEG C and the temperature is maintained for more than 6 hours; after the substrate is cooled in an air-cooling method, a grinder is used for grinding both sides of the substrate; the error of the flatness of the substrate is guaranteed to be less than 0.3mm; after that, the cold pressing of diamond and a binder is carried out on the substrate with the pressure of the cold pressing of 16kg; a hot pressed stainless steel mold is then used for sintering the substrate and a blade body so as to ensure that the width S of steps at both sides of the blade body is the same; the sintering temperature reaches 780 DEG C and the time for keeping the temperature is not less than 8 hours; painting and edging are finally followed. The method of the invention adopts the heat treatment to ensure that the hardness of the substrate can achieve Rockwell hardness of above 48; the substrate after the heat treatment is ground to guarantee the flatness of both sides of the substrate, the horizontal vibration during the glass cutting is reduced; in addition, the pressure of the cold pressing of the substrate and the binder is improved, which results in the uniform force bearing of both sides of the blade body when cutting and a neat and straight cutting slot.

Description

A kind of production method of special diamond saw blade for glass cutting technical field The invention relates to a production process of a special diamond saw blade for glass cutting. Background technique The main structure of the diamond saw blade is to fix the cutter body on the outer edge of the substrate. At present, domestically produced diamond saw blades are mainly used for cutting stone, granite, etc. In these occasions, the cutting quality requirements of diamond saw blades are not high, but the cutting length and single cutting time of saw blades are simply higher. With the development of society, glass products are used in the walls of many high-rise buildings. The wide application of glass walls makes the whole society have higher and higher requirements for glass cutting. Traditional glass cutting mainly uses diamond glass cutters or hard alloy tools. The defects of these two kinds of diamond saw blades are: the thickness of cutting glass is small, the cut...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B33/10

Inventor 骆志高吴益李举王祥

Owner 江苏益林金刚石工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com