Coil-winding wire carding machine

A wire and coil technology, applied in the field of coil winding auxiliary tools in power systems, can solve the problems of slow construction speed and unguaranteed coil winding quality, and achieve the effect of flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

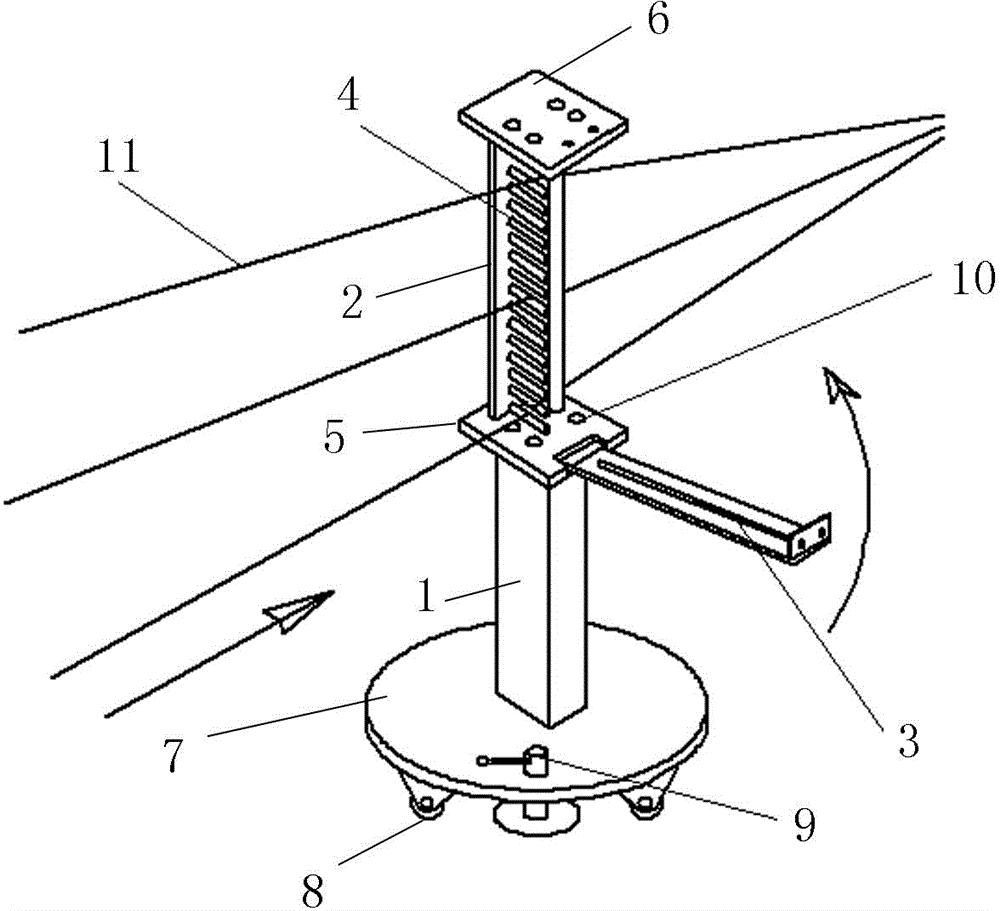

[0023] Such as figure 1 As shown, the bottom of the body 1 is provided with a reinforced base 7, and the reinforced base 7 is provided with a direction adjustment device. The structure of the direction adjusting device is as follows: a steering wheel 8 is arranged under the base 7, and two positioning discs 9 are arranged on the base; the two positioning discs are symmetrically arranged on both sides of the body 1. The two sides of the bottom plate 5 of the device body are respectively provided with splints I 2 and splints II 3, the splint I and the base plate are fixedly connected, and the splint II and the base plate are connected through a shaft rotation; a guide rod 4 is arranged between the splint I and the splint II, One end of the guide rod is fixed on the splint I, and the other end is flexibly connected to the splint II; the number of guide rods is 25 laterally; the gap between the guide rods is greater than the diameter of the wire 11.

[0024] The bottom plate is p...

Embodiment 2

[0026] The structure of the direction adjusting device is that a universal wheel is arranged under the base, and a fixed card seat is arranged on the universal wheel. Both the clamping plate I, the clamping plate II and the base plate are connected through shaft rotation. The two ends of the guide rod are respectively movably connected to the splint I and the splint II; other structures are the same as in the first embodiment.

[0027] When in use, open the splint, put multiple wires between the guide rods one by one, close the splint, adjust the direction, and unscrew the positioning plate. When the coil is wound, the wire flows through the gaps of the rollers to ensure time-saving and labor-saving, so as to solve the problems of low winding quality and slow construction speed of transformer coils, save labor costs, and reduce labor intensity. Coil winding process level The improvement ensures the quality of the product, improves the work efficiency, and saves 3 construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com