Spraying device for hub production

A technology of spraying device and wheel hub, which is applied in the direction of spraying device, liquid spraying device, and device for coating liquid on the surface, etc. It can solve the problems of low efficiency and action time difference, and achieve the effects of preventing vibration, improving efficiency, and high coincidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

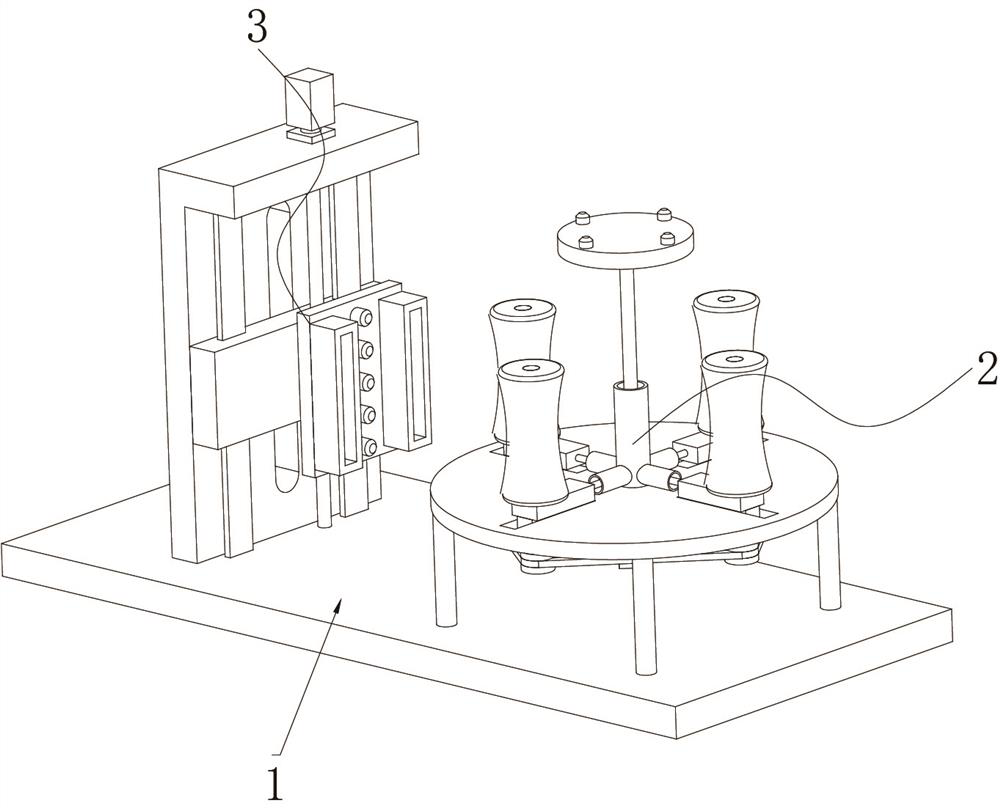

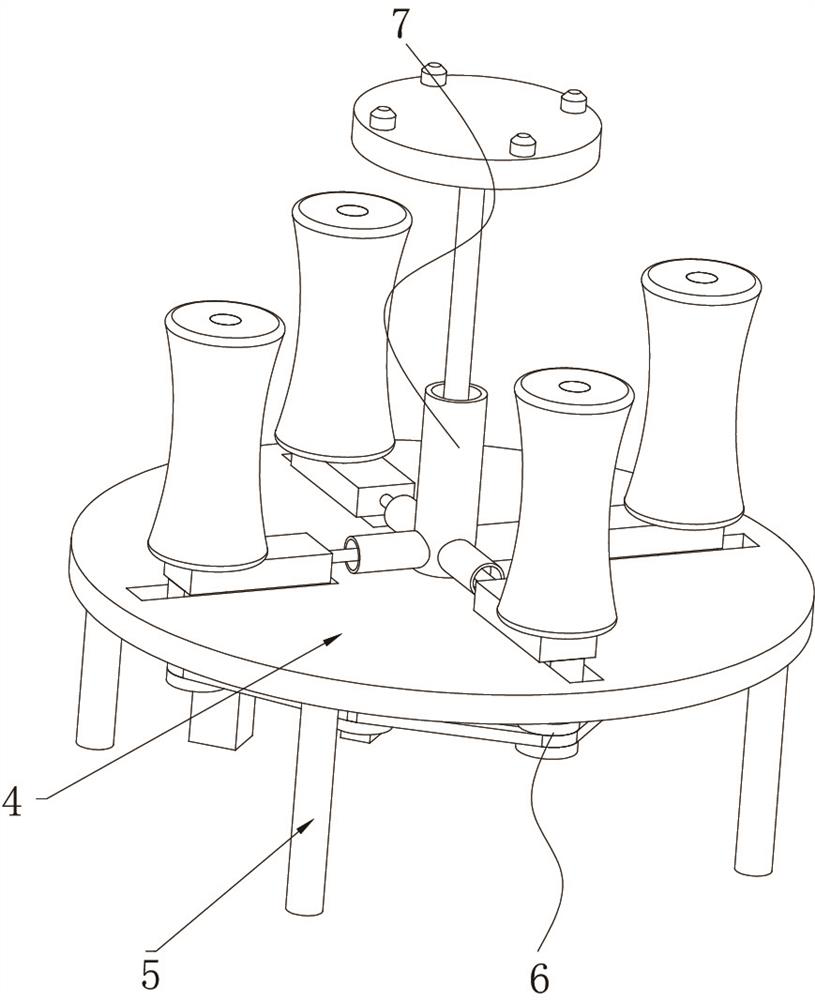

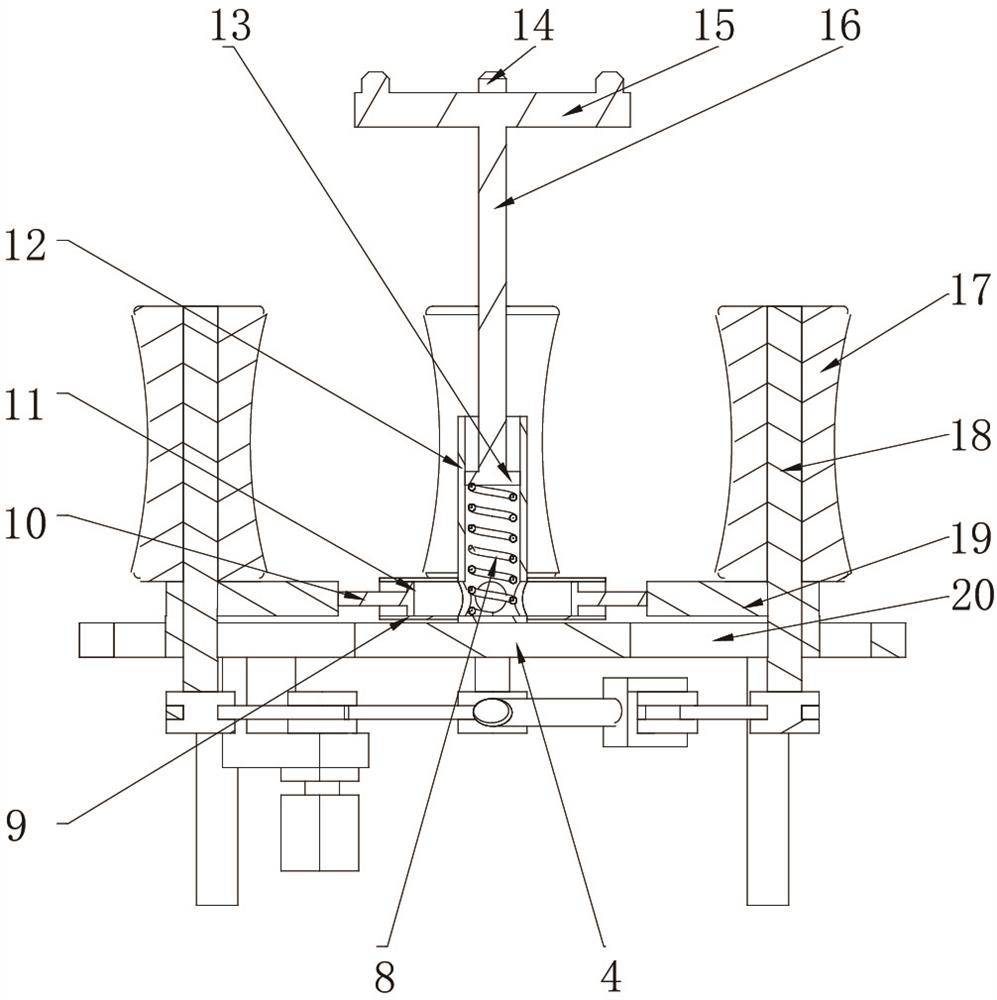

[0034] A spraying device for wheel hub production, such as Figure 1-3As shown, it includes a base 1 and a clamping drive mechanism 2 and a spraying mechanism 3 that are arranged on the top of the base 1 and cooperate with each other. The driving assembly 6 and the clamping assembly 7 on both sides of the support base 4 and cooperating with each other, the clamping assembly 7 includes a support plate 15 and a clamping curved roller assembly 17, and the bottom outer wall of the support plate 15 is rotatably connected with a connecting rod Two 16, the outer wall of the connecting rod two 16 is fixed with the piston two 13 by bolts, the outer wall of the piston two 13 cooperates to slide with the main cylinder body 12, and the outer wall of the main cylinder body 12 is welded with the branch cylinder body 9 communicating with its inner cavity, the branch cylinder The inner wall of the body 9 cooperates and slides with a piston-11, the outer wall of the piston-11 is fixed with a c...

Embodiment 2

[0039] A spraying device for wheel hub production, such as Figure 7 , 8 As shown, in order to solve the problem of cushioning and friction; this embodiment makes the following improvements on the basis of Embodiment 1: the clamping curved roller assembly 17 includes a roller body 40 and a buffer film 41 arranged on the outer wall of the roller body 40, The buffer film 41 includes two symmetrical side ribs 43 obliquely bonded to the outer wall of the roller body 40 and a support rib 42 bonded to the outer wall of the roller body 40, the support rib 42 is located on the axis of symmetry of the two side ribs 43 Location.

[0040] When this embodiment is in use, on the one hand, the arrangement of the support rib 42 and the side rib 43 can further buffer the collision between the roller body 40 and the hub to prevent damage; on the other hand, the support rib 42 and the side rib 43 Designed with a high triangular structure, when the clamping force is small, the shrinkage of the...

Embodiment 3

[0042] A spraying device for wheel hub production, such as Figure 7 , 8 As shown, in order to solve the spraying problem; the present embodiment makes the following improvements on the basis of embodiment 1 and embodiment 2: the spraying mechanism 3 includes an "L" type bracket 28 and a spray nozzle 32, and the "L" type bracket 28 is fixed on the top outer wall of the base 1 by bolts, and the outer wall of the "L"-shaped bracket 28 is slidably connected with a lifting plate 34 through a linear slide rail 35, and the outer wall of the lifting plate 34 is provided with an adjustment plate 31, and the spray nozzle 32 Be fixed on the outer wall of the adjusting plate 31 by bolts, and the spray nozzle 32 is connected to the outer wall spray pump; when the spray pump starts, the spray medium can be delivered to the spray nozzle 32, so that the medium is sprayed to the surface of the hub by the spray nozzle 32; Both sides of the symmetry of the spray nozzle 32 are provided with div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com