Method for prolonging service life of turbine blade based on laser double-faced impact technique

A turbine blade, double-sided technology, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of large deformation of impact parts, cumbersome workload, and inconspicuous strengthening effect, so as to save costs and realize automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

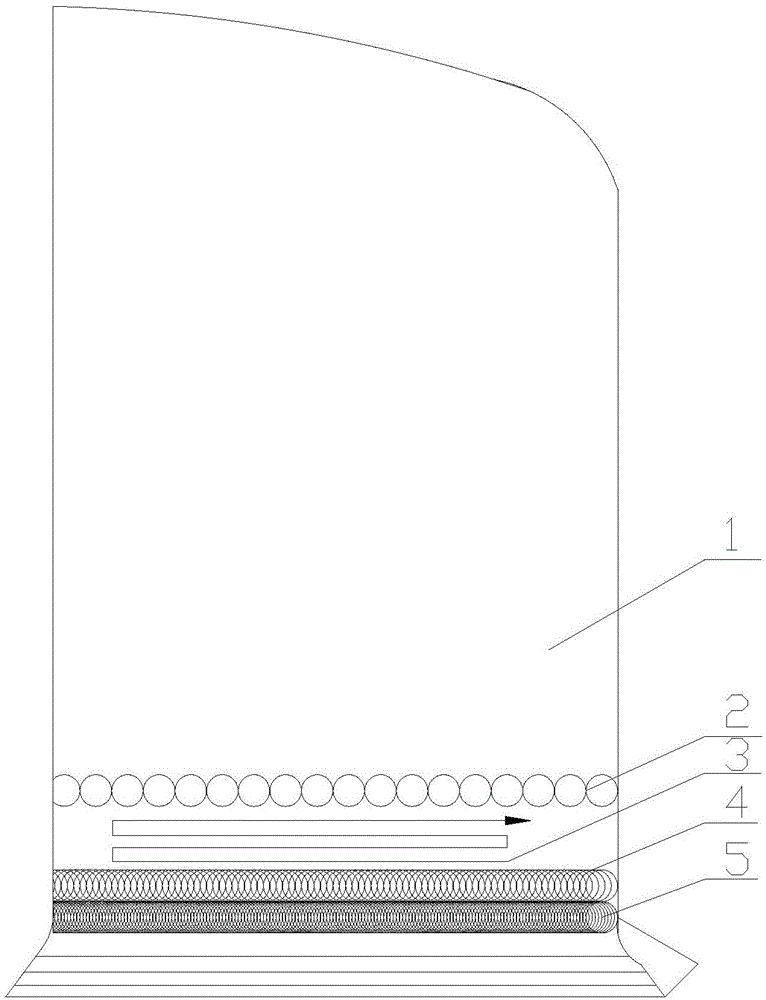

[0025] Such as figure 1 As shown, the specific process of improving the life of turbine blades based on laser double-sided shock technology is:

[0026] A pulsed solid-state laser is used, and the pulsed laser is split into two beams of 6j with a spot diameter of 4mm to ensure that the pulsed laser is simultaneously impacted on the front and back sides of the turbine blade 1;

[0027] The fixture fixes the turbine blade 1, the laser absorbing material is attached to the outside of the blade, and the flowing water is used as the constraining layer. The pulsed laser impacts the bottom layer of the root of the blade at the same time with the laser spot 5 with an overlap rate of 90%, until the impact spot completely acts on the absorbing material up to

[0028] The height of the spot diameter is 4mm when the lifting table is lowered. The laser spot 4 with an overlap rate of 80% acts on the blade at the same time on both sides until the impact spot is completely applied to the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com