A concrete strength test device for civil construction

A technology for concrete strength and civil engineering, which is applied in the direction of measuring devices, strength characteristics, and the use of stable bending force to test the strength of materials, etc., can solve the problems of messy workbench, difficult residue, unfavorable experiments, etc., and reduce experimental data deviation, improve cleaning efficiency, and avoid experimental deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

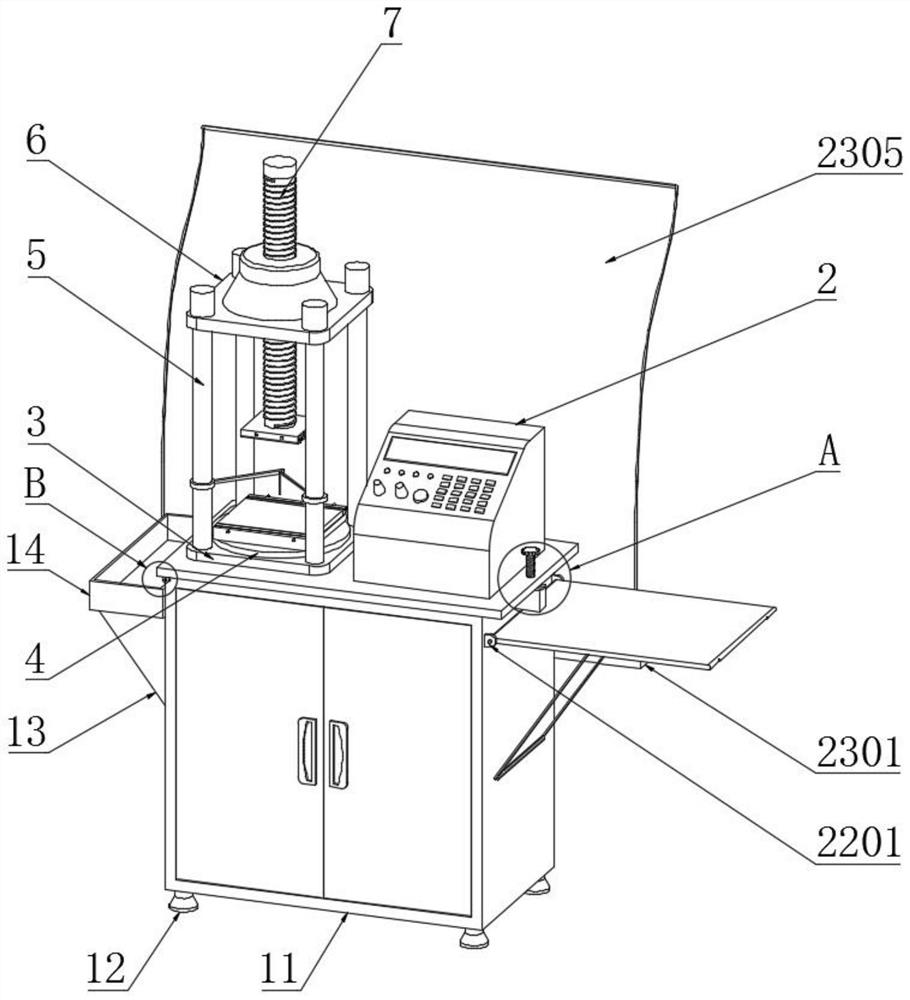

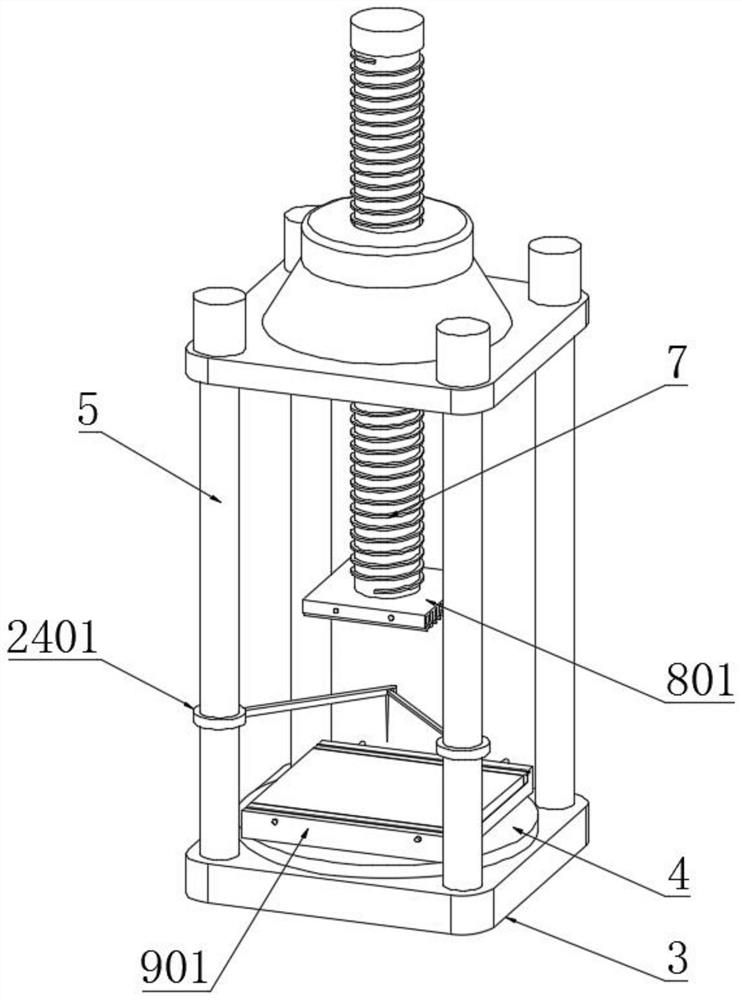

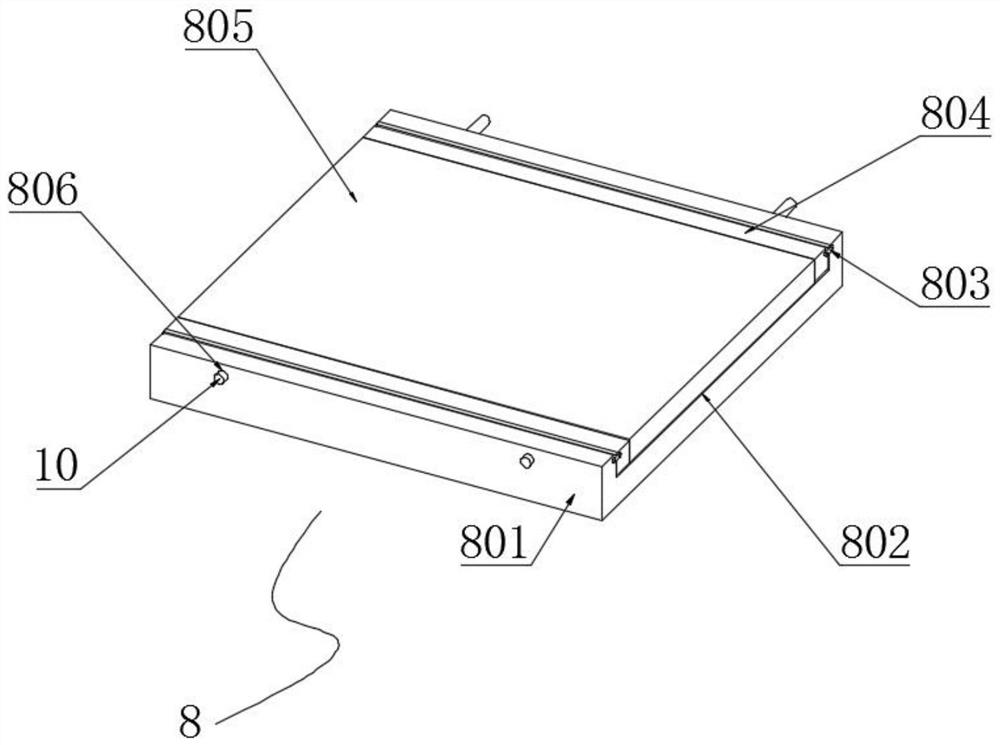

[0049] Example: as Figure 1-10 As shown, the present invention provides a technical solution, a concrete strength test device for civil construction, comprising a workbench 1, a control box 2 is installed on one side of the top of the workbench 1, and a lower mounting seat is installed on the other side of the top of the workbench 1 3. An induction base 4 is installed at the top of the lower installation base 3, an upper installation base 6 is installed at the top of the lower installation base 3 through a column 5, a pressure rod 7 is installed in the middle of the upper installation base 6, and a support assembly 8 is installed at the top of the induction base 4. The assembly 8 includes a test piece support plate 801, a groove 802, a two-hole corner code 803, a spacer block 804, an auxiliary spacer block 805 and a first locking hole 806;

[0050] A sample support plate 801 is installed at the top of the induction base 4, and a groove 802 is formed at the top of the sample s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com