Method for testing lap joint fracture resistance of bamboo skin rolls

A test method, bamboo strip roll technology, applied in the direction of applying stable tension/compression to test material strength, measuring device, strength characteristics, etc., can solve the problem of large impact and cannot fully, accurately and truly reflect the fracture resistance of bamboo composite pressure pipes Performance, fracture resistance and other issues, to achieve high accuracy, simple and fast test method, to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

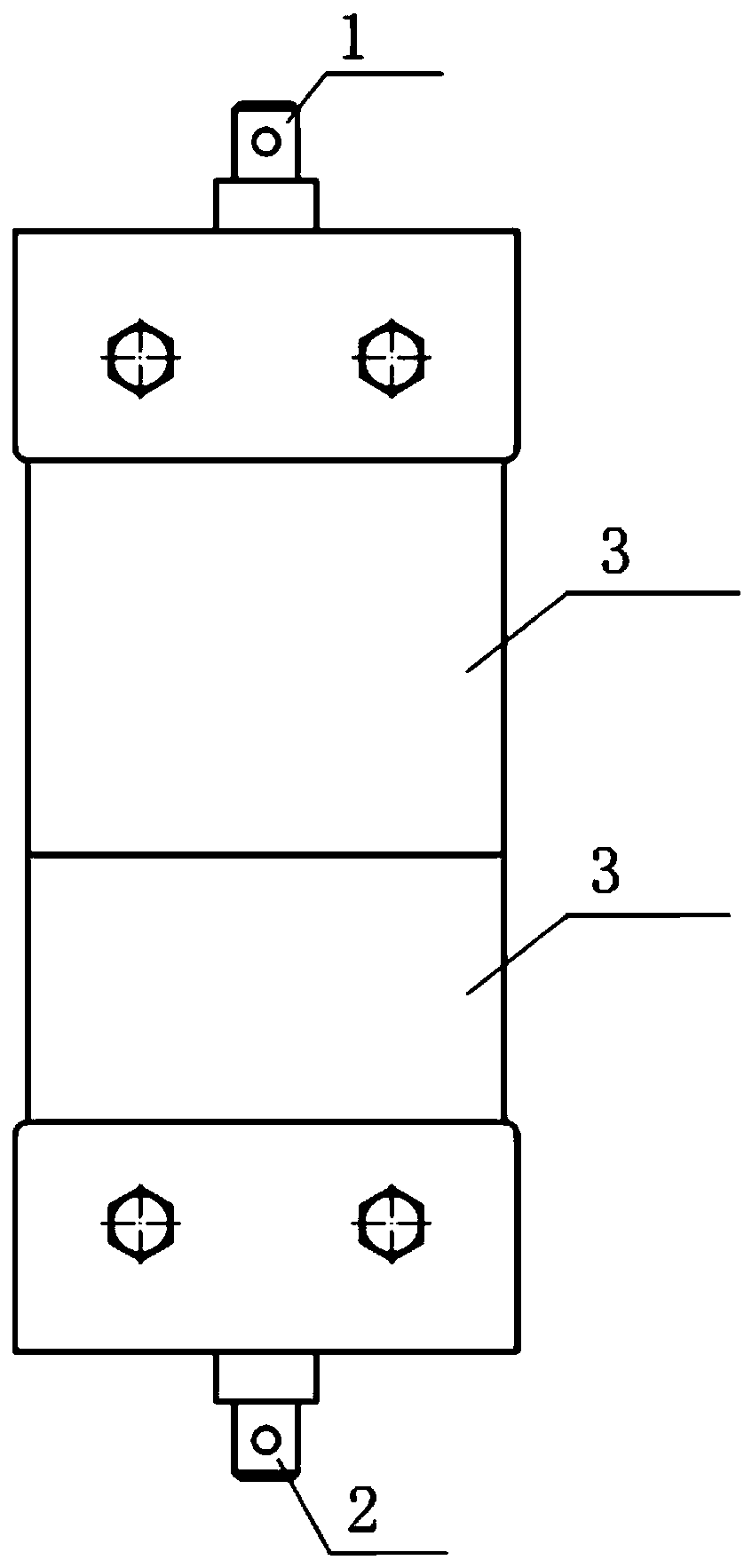

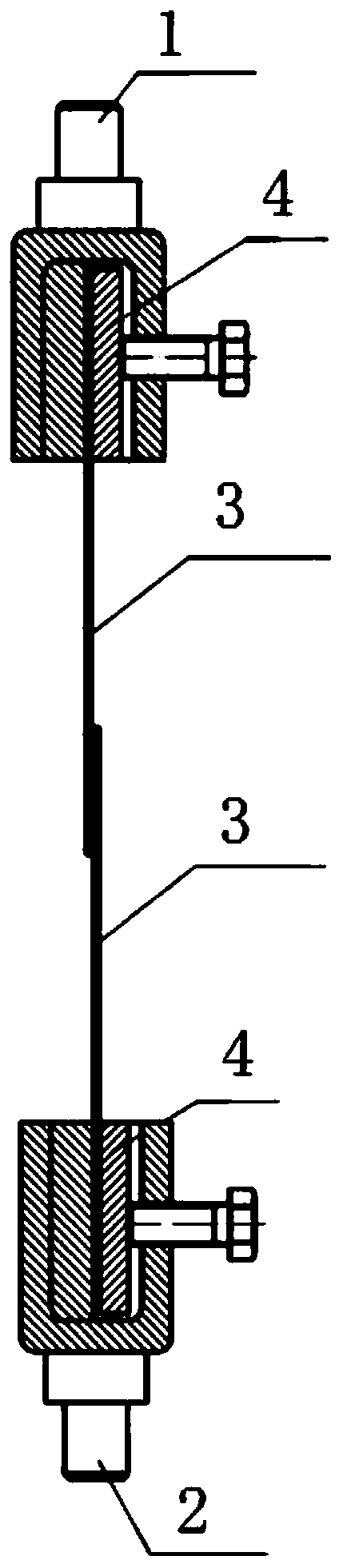

[0034] First prepare the sample. Cut a sample to be tested with a length of L along the length of the bamboo strip roll to be tested, cut n samples to be tested from N rolls of bamboo strips, and the cut samples to be tested must include the upper roll, the lower roll and the lap surface;

[0035] Preferably (according to the optimal number of samples obtained by multiple tests):

[0036] When 1≤N≤90, n=5;

[0037] 91≤N≤150, n=8;

[0038] When 151≤N≤500, n=13;

[0039] When 501≤N≤1200, n=20;

[0040] When 1201≤N≤3200, n=32;

[0041] When 3201≤N, divide N into 3200x+y (1≤y<3200), n=32X+n' (1≤y≤90, n'=5; 91≤y≤150, n'=8; 151 When ≤y≤500, n'=13; when 501≤y≤1200, n'=20; when 1201≤y≤3200, n'=32)

[0042] Further, it is necessary to ensure that the lap center line of the lap surface is located at the center of the sample to be tested, and the lap line is parallel to the cutting line plane at both ends of the sample. The overlapping line is parallel to the cutting line to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com