Manufacturing device and method of vibration measuring tube

A vibration measurement and manufacturing device technology, applied in the field of mold manufacturing, can solve the problems of low manufacturing precision of vibration measuring tubes, and achieve the effects of fast processing speed, guaranteed precision and guaranteed precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

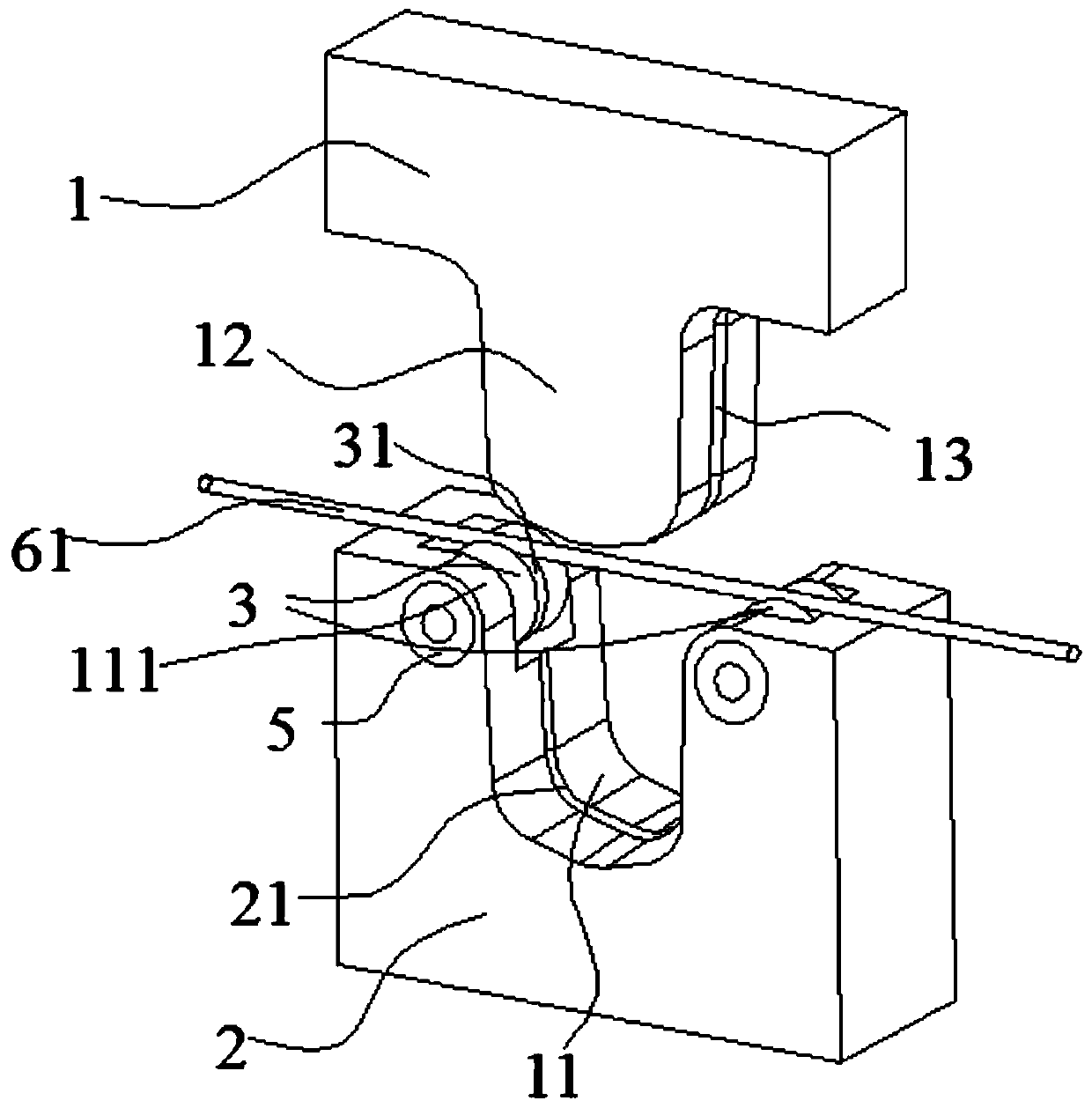

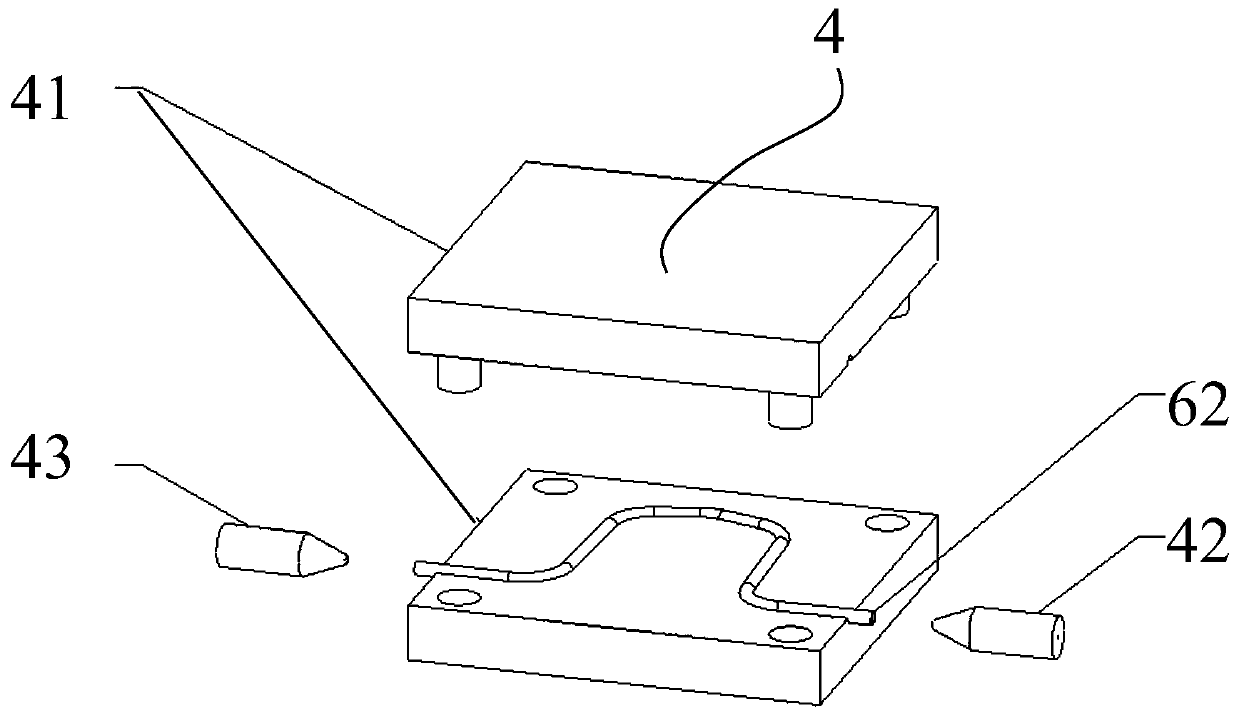

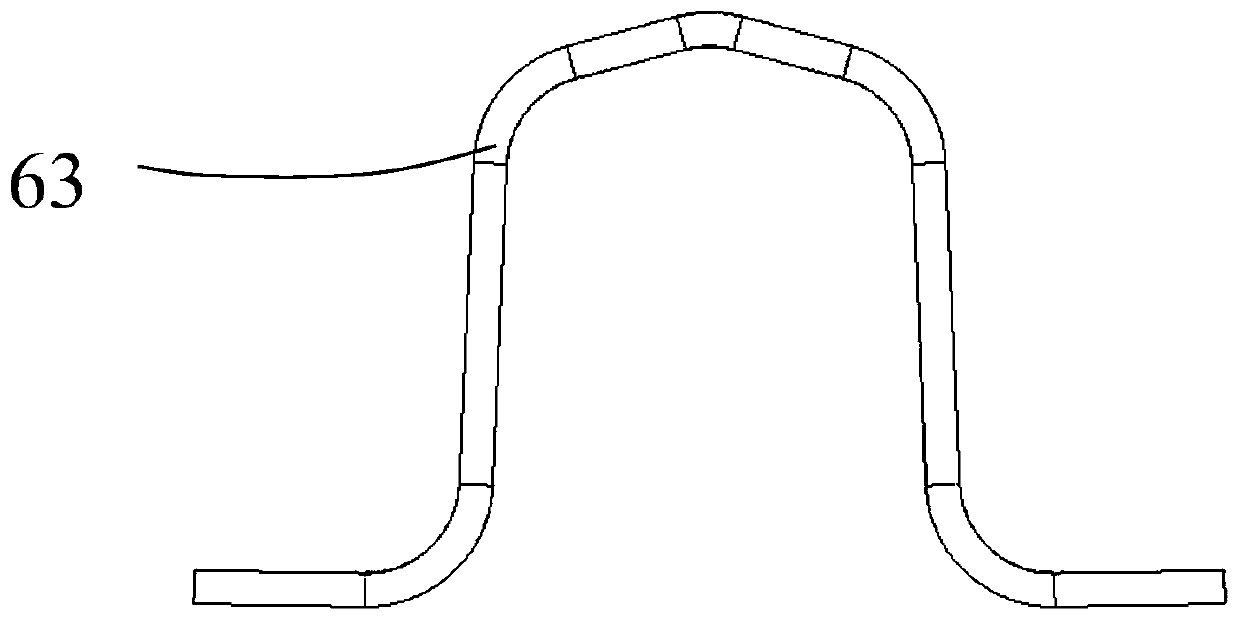

[0023] Embodiment: a kind of manufacturing device of vibrating measuring tube, as figure 1 As shown, it includes an upper mold 1 and a lower mold 2. The middle part of the lower mold has a depression 21 that the lower part of the upper mold can be inserted into. In the plane, the lower mold is provided with a lower mold pressure groove 22 corresponding to the upper mold, the centerlines of the upper mold pressure groove and the lower mold pressure groove are on the same plane, and the two sides of the lower mold depression are respectively provided with a gap between the measuring tube and the lower mold to reduce vibration. The friction roller mold 3, the axis of the roller mold is perpendicular to the center line of the lower mold pressure groove, the roller mold and the lower mold are connected by precision bearings 5, the two ends of the roller mold are respectively fixedly sleeved with the precision bearing inner ring, and the two precision bearing outer rings It is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com