Automatic initial failure device for continuous collapse test of rectangular rod piece space structure

A space structure and rod technology, which is applied in the field of automatic initial failure device for continuous collapse test of rectangular rod space structure, can solve the problems of manual operation, difficulty in ensuring test accuracy and safety, and inability to use rectangular cross-section rods, etc. Achieve high repeatability, easy installation, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

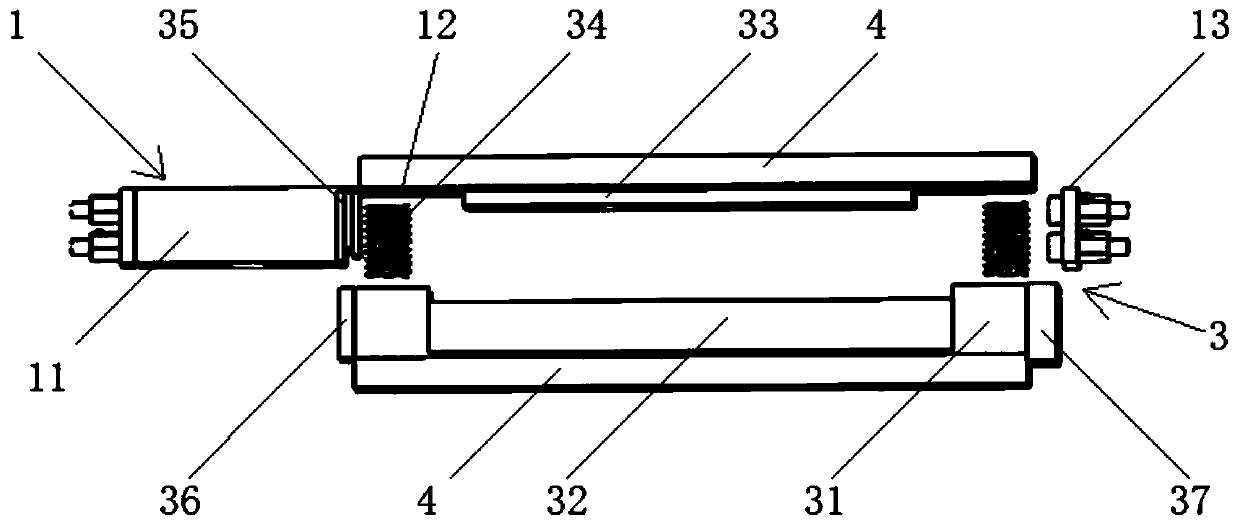

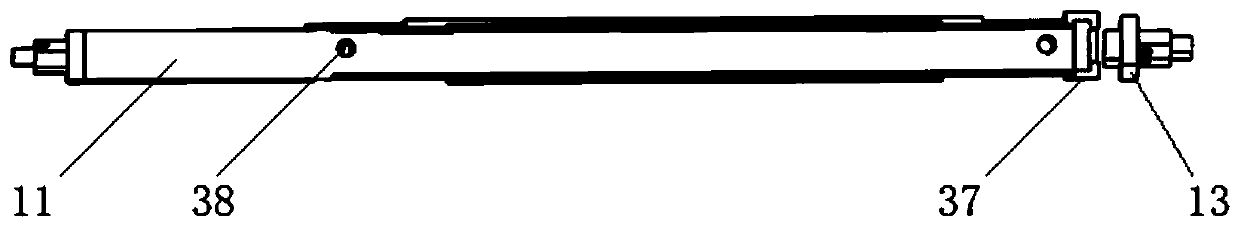

[0109] Considering machining error, convenient installation and meeting the requirements of bar bearing capacity, the thickness of all chute webs and flanges should be twice as thick as the rectangular tube wall thickness, and the web thickness bottom of the second chute 36 is larger than the opening of the first chute 35 The width is 0.5mm-1mm smaller, the web thickness of the first chute 35 is 0.5mm-1mm smaller than the opening width of the second chute 36, and the opening width of the third chute 37 is greater than the thickness of the rod sealing plate 13 by 0.5mm- 1mm, the length of the stiffener 4 is 10mm-15mm greater than the opening length of the open rectangular tube 31, and the diameter of the mounting hole 38 is not greater than 0.3 times the width of the open rectangular tube 31.

[0110] During the use of the initial failure device 3 of the present invention, lubricating oil can be applied inside each chute and around the rod sealing plate 13 to reduce the friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com