Method for increasing initial coulomb efficiency of nickel-containing cathode material of lithium ion battery and application thereof

A lithium-ion battery and coulombic efficiency technology, which is applied in the field of electrochemistry, can solve the problems of increased alkalinity of synthetic positive electrode materials, increased gram capacity of sacrificial materials, and increased gas production, so as to achieve the optimal matching of first-time efficiency, improve first-time coulombic efficiency, and reduce The effect of excess amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

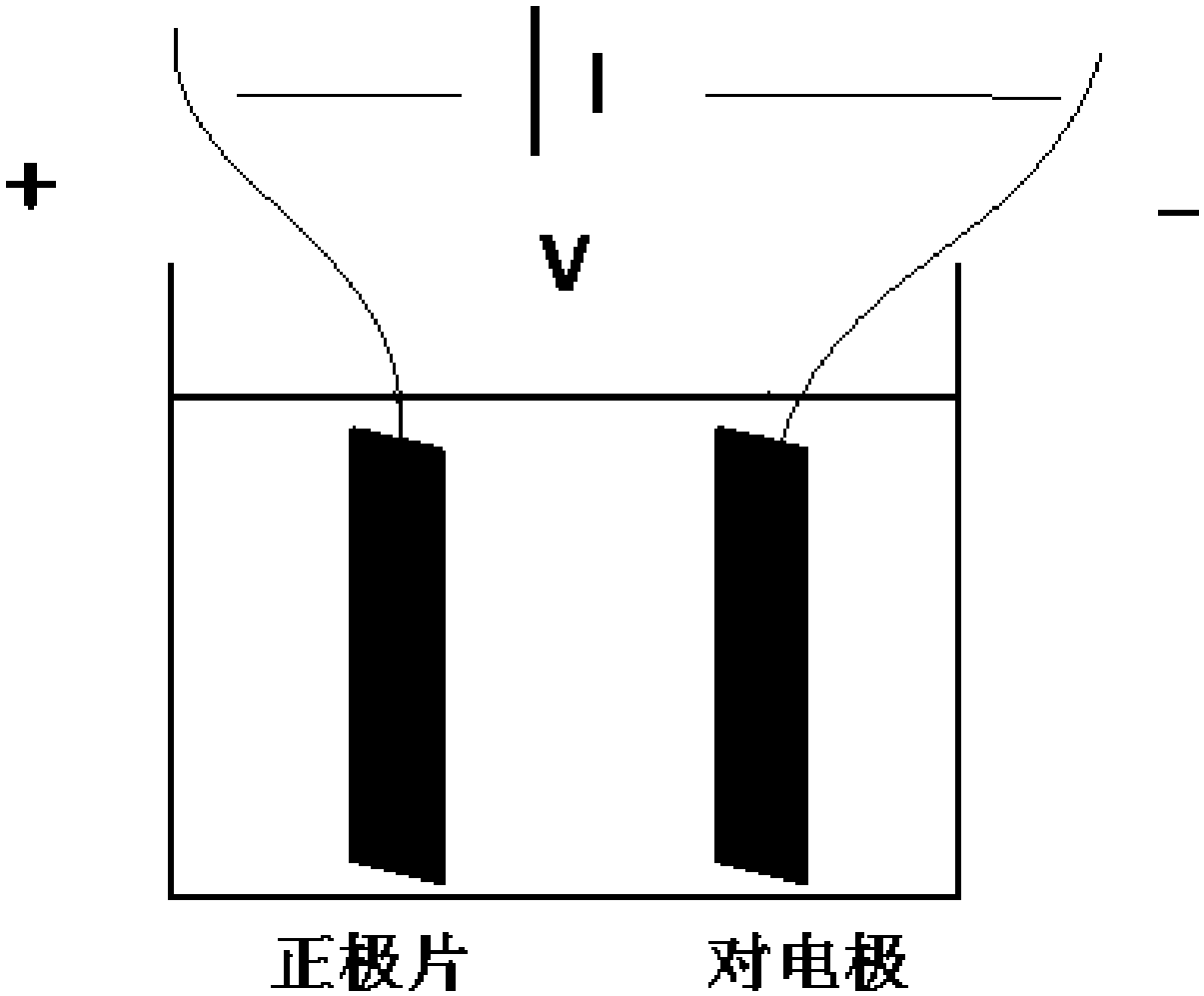

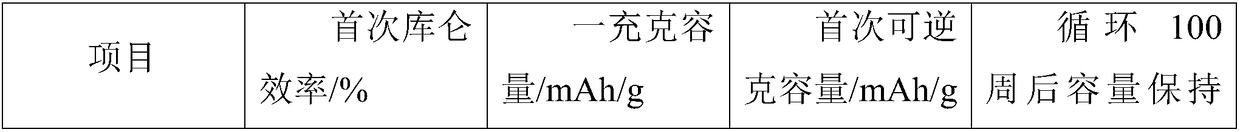

[0052] as attached figure 1 As shown, the positive electrode material of nickel cobalt lithium manganese oxide NCM523 with a charging capacity of 206mAh / g and an initial efficiency of 85% and the binder PVDF2% and conductive agent SP2% are used according to the ratio of the active material of the positive electrode material to 96%. 16.86mg / cm 2 The loading capacity of the pole piece is evenly coated on one side of the 12μ aluminum foil with an effective coating area of 20cm×15cm. The first charge capacity of this pole piece is 1000mAh. figure 1 Put it in the electrolyte in the same way, use a 1mm thick lithium sheet as the counter electrode, connect the aluminum foil and the lithium sheet to the positive and negative electrodes of the external power supply, charge with a current of 0.05C, that is, 50mAh for 2h, take out the positive electrode sheet, and take a part Pole sheet production The reversible capacity of the positive electrode material was tested with a 2320 button...

Embodiment 2

[0054] as attached figure 1 As shown, the positive electrode material of nickel cobalt lithium manganese oxide NCM523 with a charging capacity of 206mAh / g and an initial efficiency of 85% and the binder PVDF2% and conductive agent SP2% are used according to the ratio of the active material of the positive electrode material to 96%. 16.86mg / cm 2 The loading capacity of the pole piece is evenly coated on one side of the 12μ aluminum foil with an effective coating area of 20cm×15cm. The first charge capacity of this pole piece is 1000mAh. figure 1 Put it in the electrolyte in the same way, use a 1mm thick lithium sheet as the counter electrode, connect the aluminum foil and the lithium sheet to the positive and negative electrodes of the external power supply, charge with a current of 0.05C, that is, 50mAh for 3h, take out the positive electrode sheet, and take a part Pole sheet production The reversible capacity of the positive electrode material was tested with a 2320 button...

Embodiment 3

[0056] as attached figure 1 As shown, the positive electrode material of nickel cobalt lithium manganese oxide NCM523 with a charging capacity of 206mAh / g and an initial efficiency of 85% and the binder PVDF2% and conductive agent SP2% are used according to the ratio of the active material of the positive electrode material to 96%. 16.86mg / cm 2 The loading capacity of the pole piece is evenly coated on one side of the 12μ aluminum foil with an effective coating area of 20cm×15cm. The first charge capacity of this pole piece is 1000mAh. figure 1 Place it in the electrolyte in the best way, use a 1mm thick lithium sheet as the counter electrode, connect the aluminum foil and the lithium sheet to the positive and negative electrodes of the external power supply, and charge it to 4.4V with a current of 0.05C, that is, 50mAh constant current and constant voltage, 0.02 C is cut off, and then discharged to 2.75V with a current of 0.05C, the positive electrode piece is taken out, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gravimetric energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap