Pure-dry-process desulfurization equipment

A dry desulfurization and equipment technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of large equipment, high operating technical requirements, and large floor space, so as to reduce corrosion damage and achieve high desulfurization. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention, not to limit the scope of the present invention.

[0034] For those skilled in the art, it should be clear that the direction words such as "front, back, up, down, left, right" mentioned in this application are only for explaining the present invention more intuitively, so the above-mentioned words in the text The words used in the direction do not constitute a limitation on the protection scope of the present invention.

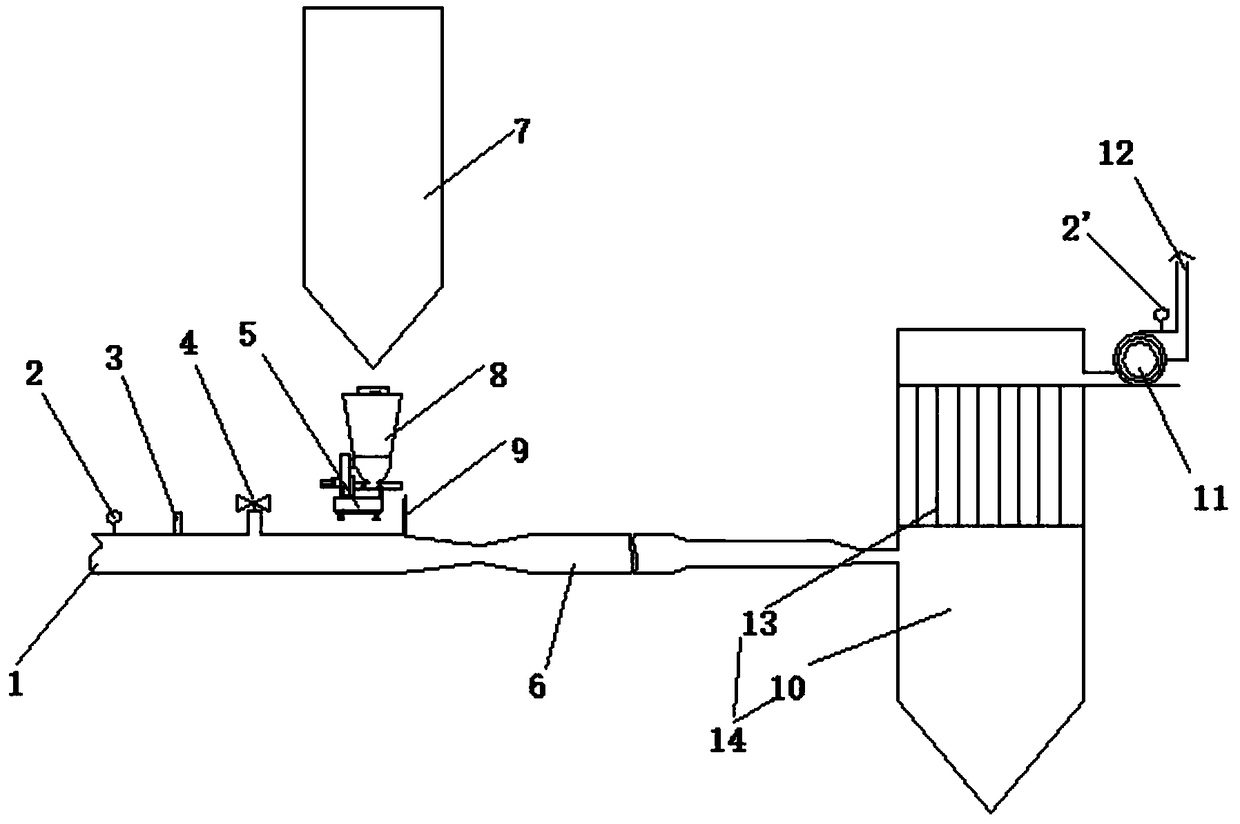

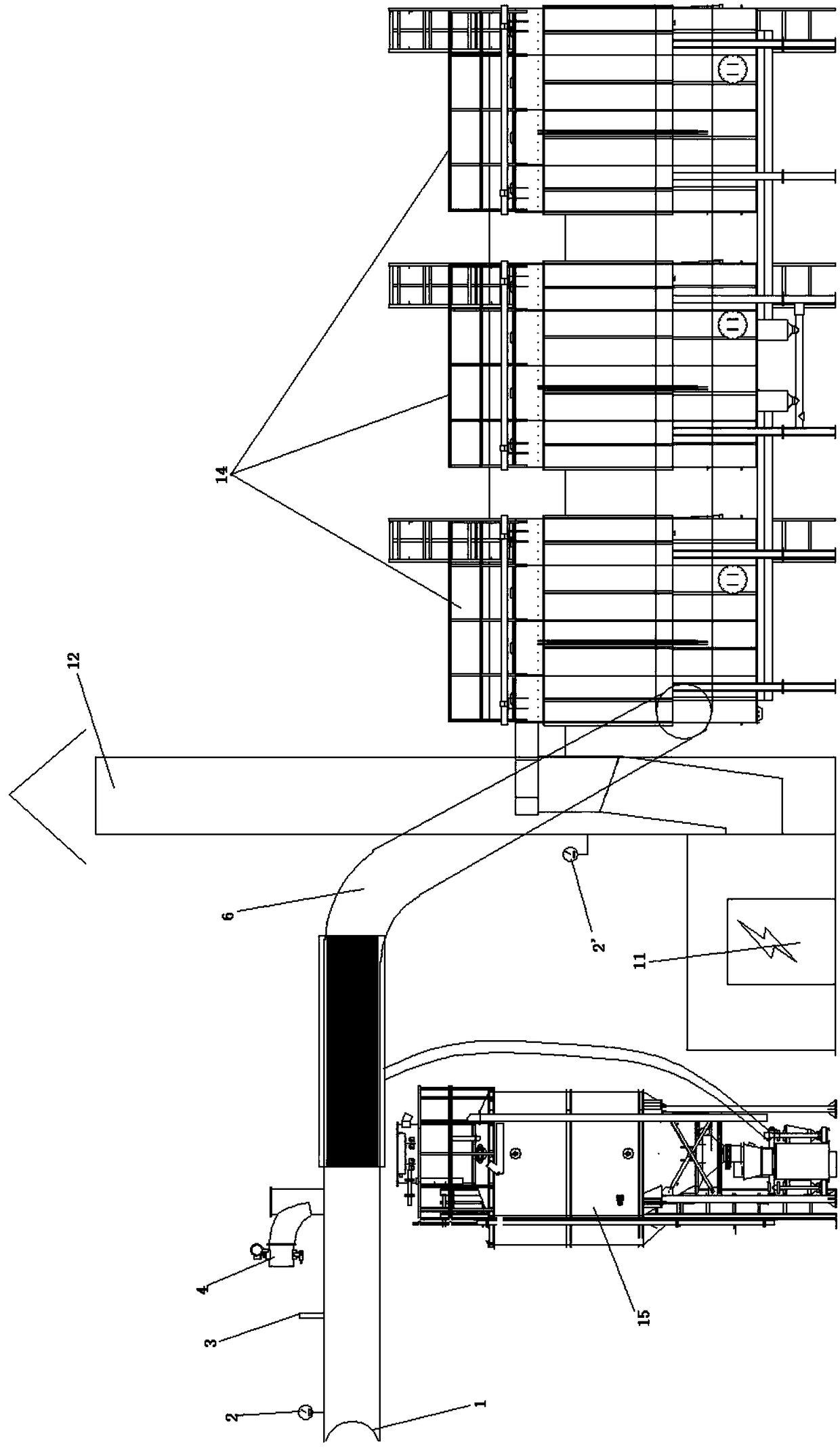

[0035] Such as figure 1 with figure 2 As shown, a pure dry desulfurization equipment includes a flue gas pipeline conveying system, an adsorption dust removal system 14, a desulfurizing agent filling system 15, an air supply system and a detection system. The desulfurizer filling system and the adsorption dedusting system form a Venturi tube feeding-negative pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com