Paper pulp stirring and filtering device with multiple stirring modes

A technology for filtering equipment and pulp, applied to mixers with rotating stirring devices, mixer accessories, mixing methods, etc., can solve the problems of pulp debris sedimentation filtration, pulp stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

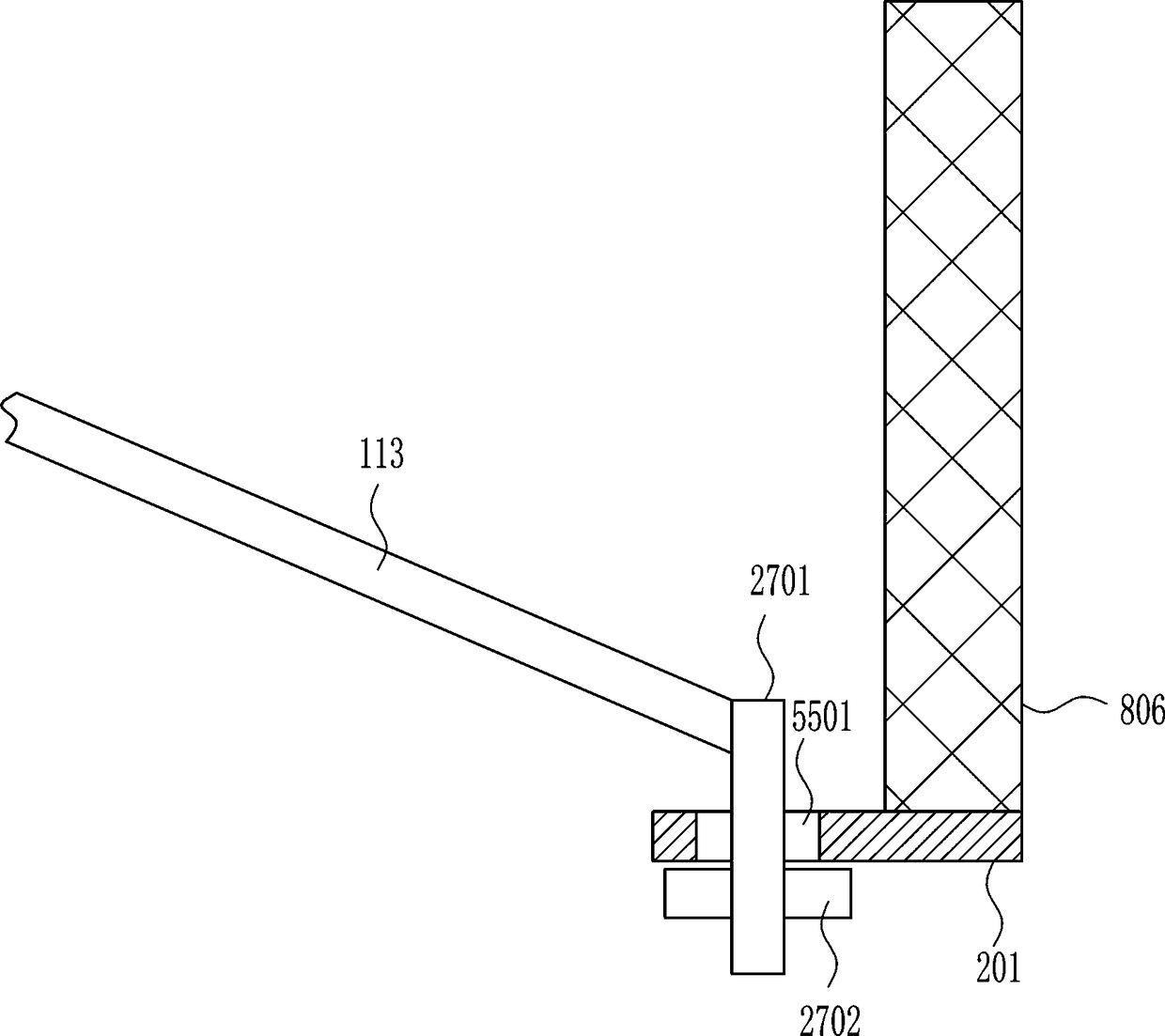

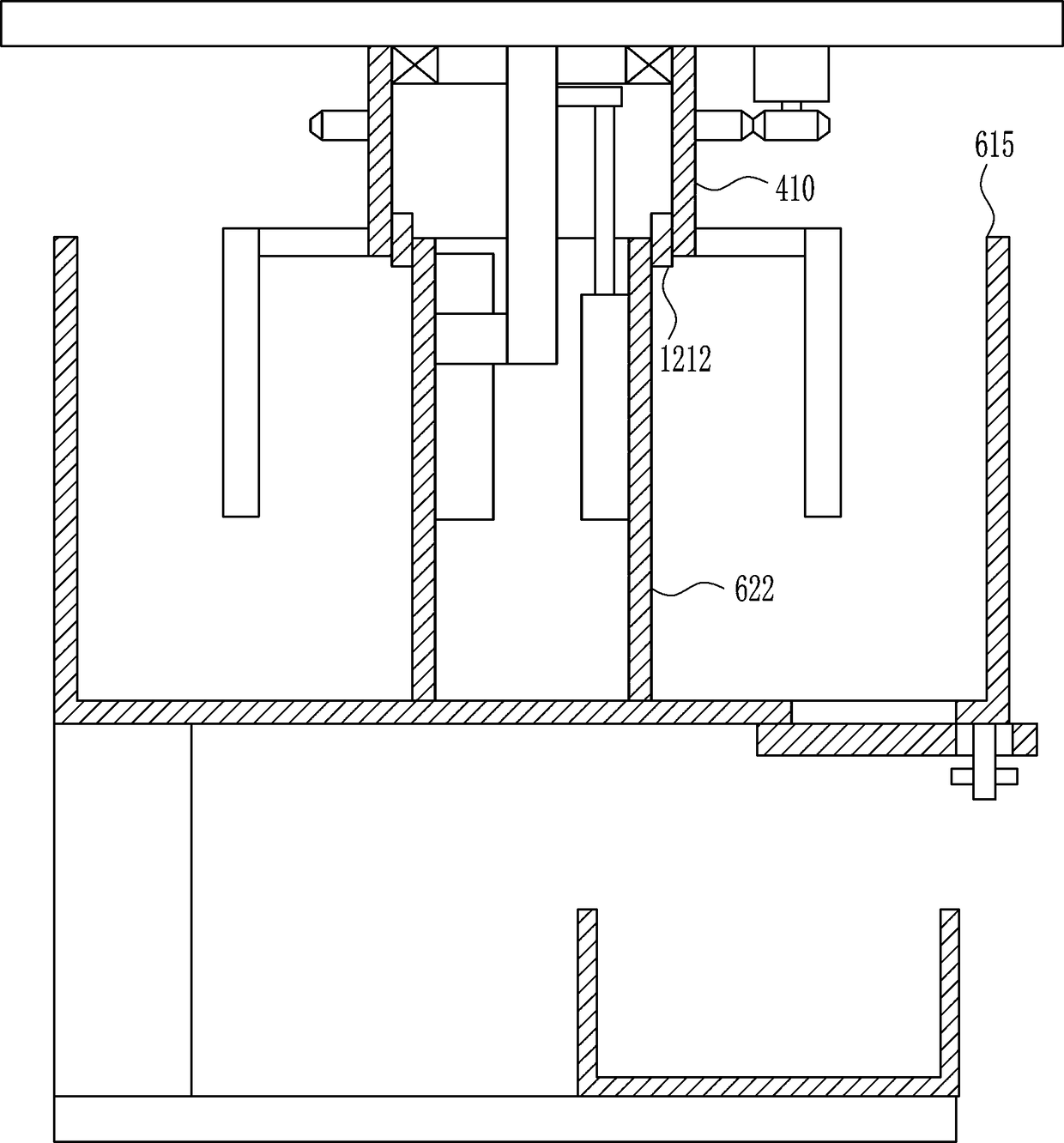

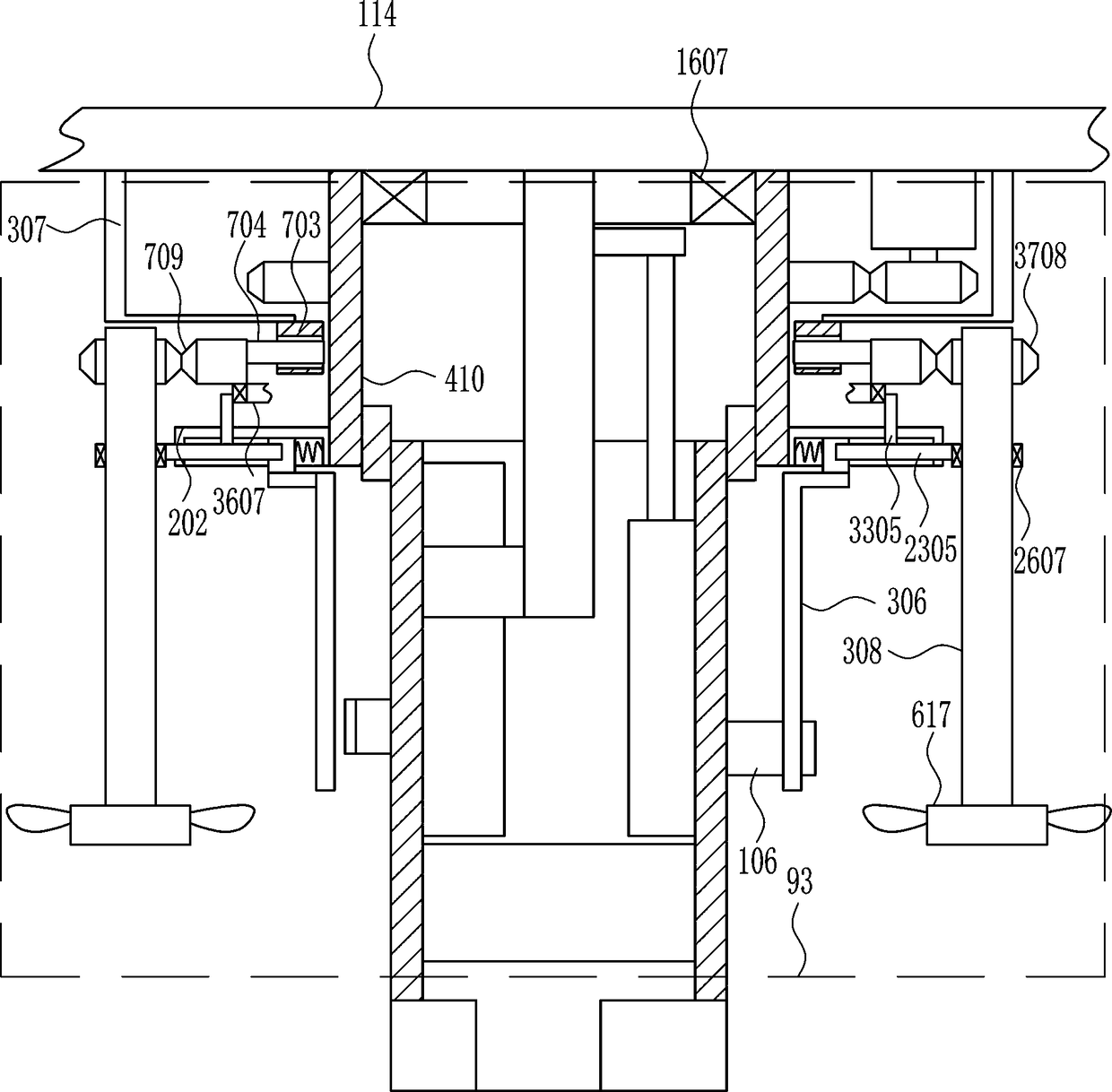

[0033] A pulp stirring and filtering device with multiple stirring methods, such as Figure 1-8 As shown, it includes a bottom plate 101, a collection box 610, a support plate 104, a placement box 615, a first screw rod 1701, a baffle plate 115, a first nut 1702, a fixing ring 622, a first slide rail 1705, a first slide block 1706, The first push rod 1305, the cover plate 114, the first bearing seat 1607, the rotating ring 410, the connecting block 202, the rotating rod 308, the first gear 1708, the motor 601, the second gear 2708, the pushing block 209 and the cylinder 602, the bottom plate 101 A collection box 610 is placed on the upper right side, a support plate 104 is connected to the upper left side of the bottom plate 101 by welding, a placement box 615 is installed on the upper end of the support plate 104 by bolts, and a first storage box 615 is opened on the right side of the lower side of the placement box 615. Through hole 1501, the lower right side of the storage ...

Embodiment 2

[0035] A pulp stirring and filtering device with multiple stirring methods, such as Figure 1-8 As shown, it includes a bottom plate 101, a collection box 610, a support plate 104, a placement box 615, a first screw rod 1701, a baffle plate 115, a first nut 1702, a fixing ring 622, a first slide rail 1705, a first slide block 1706, The first push rod 1305, the cover plate 114, the first bearing seat 1607, the rotating ring 410, the connecting block 202, the rotating rod 308, the first gear 1708, the motor 601, the second gear 2708, the pushing block 209 and the cylinder 602, the bottom plate 101 A collection box 610 is placed on the upper right side, a support plate 104 is connected to the upper left side of the bottom plate 101 by welding, a placement box 615 is installed on the upper end of the support plate 104 by bolts, and a first storage box 615 is opened on the right side of the lower side of the placement box 615. Through hole 1501, the lower right side of the storage ...

Embodiment 3

[0038] A pulp stirring and filtering device with multiple stirring methods, such as Figure 1-8As shown, it includes a bottom plate 101, a collection box 610, a support plate 104, a placement box 615, a first screw rod 1701, a baffle plate 115, a first nut 1702, a fixing ring 622, a first slide rail 1705, a first slide block 1706, The first push rod 1305, the cover plate 114, the first bearing seat 1607, the rotating ring 410, the connecting block 202, the rotating rod 308, the first gear 1708, the motor 601, the second gear 2708, the pushing block 209 and the cylinder 602, the bottom plate 101 A collection box 610 is placed on the upper right side, a support plate 104 is connected to the upper left side of the bottom plate 101 by welding, a placement box 615 is installed on the upper end of the support plate 104 by bolts, and a first storage box 615 is opened on the right side of the lower side of the placement box 615. Through hole 1501, the lower right side of the storage b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap