Rapid clamping device

A clamping device and fast technology, applied in the direction of workpiece clamping device, positioning device, clamping, etc., can solve the problems of cumbersome operation, poor synchronization and low efficiency, and achieve the effect of compact size, high synchronization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

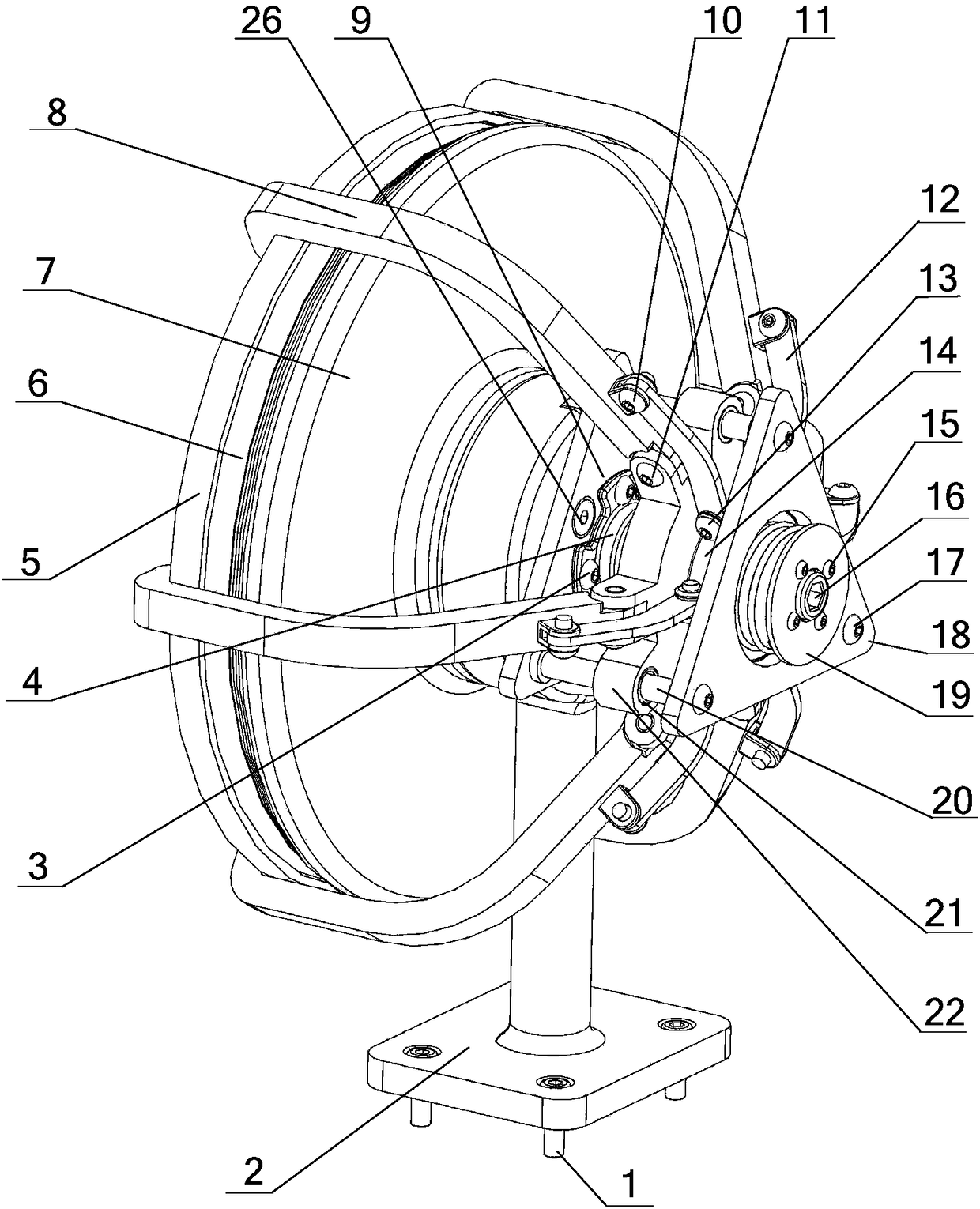

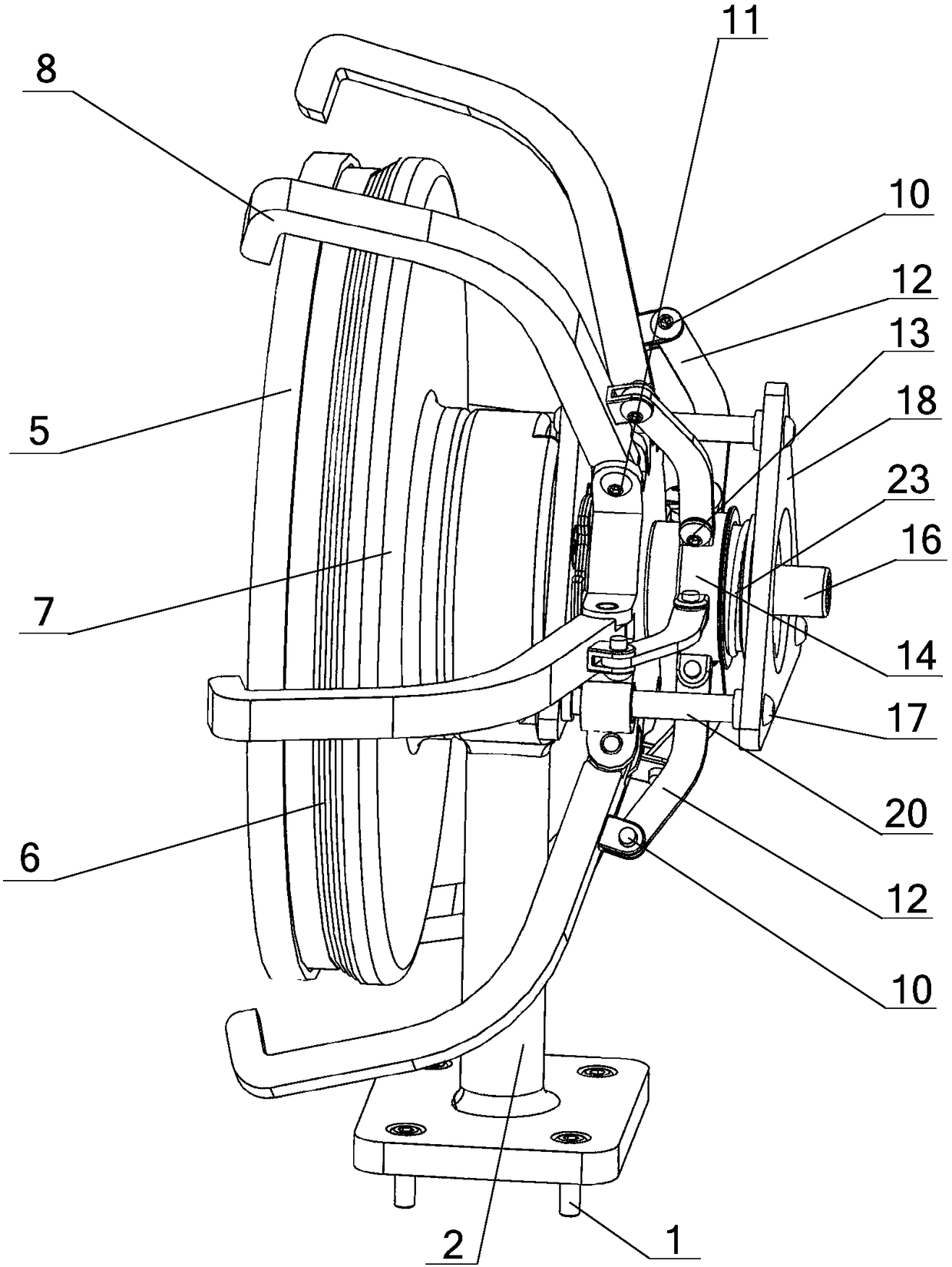

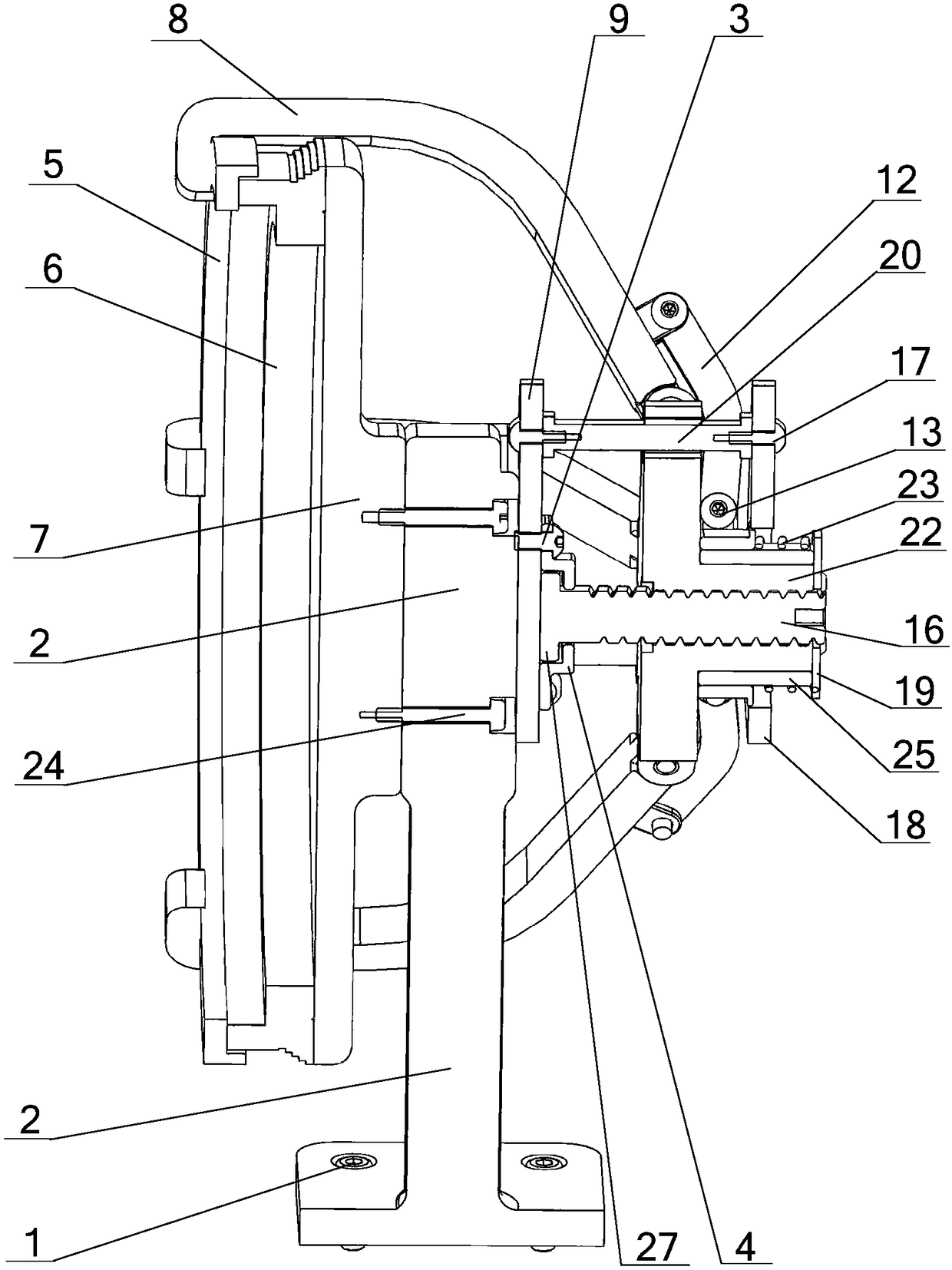

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as Figure 1~3 As shown, the present invention includes a bracket 2, a push rod end cover 4, a compression end ring 5, a compression flange 7, a pull rod 8, a top plate 9, a connecting rod 12, a synchronous slip ring 14, a push rod 16, a cover plate 18, Copper sleeve flange 19, guide shaft 20, graphite copper sleeve 21 and central pressing member 22, wherein the pressing flange 7 and the top plate 9 are installed on the upper part of the bracket 2 through the pressing flange fixing screw 24 and the top plate fixing screw 26 respectively. On both sides, the lower part of the bracket 2 is provided with bracket fixing screws 1 for connection and installation.

[0025] One end of the ejector rod 16 is provided with a boss flange 27, and the boss flange 27 is accommodated in the ejector rod end cover 4, and the ejector rod end cover 4 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com