Variable speed structure of hybrid electric vehicle

A hybrid vehicle and variable speed structure technology, applied in hybrid vehicles, motor vehicles, power units, etc., can solve problems such as single working mode, high fuel consumption of oil-powered vehicles, and inability to meet user needs well, to overcome energy high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

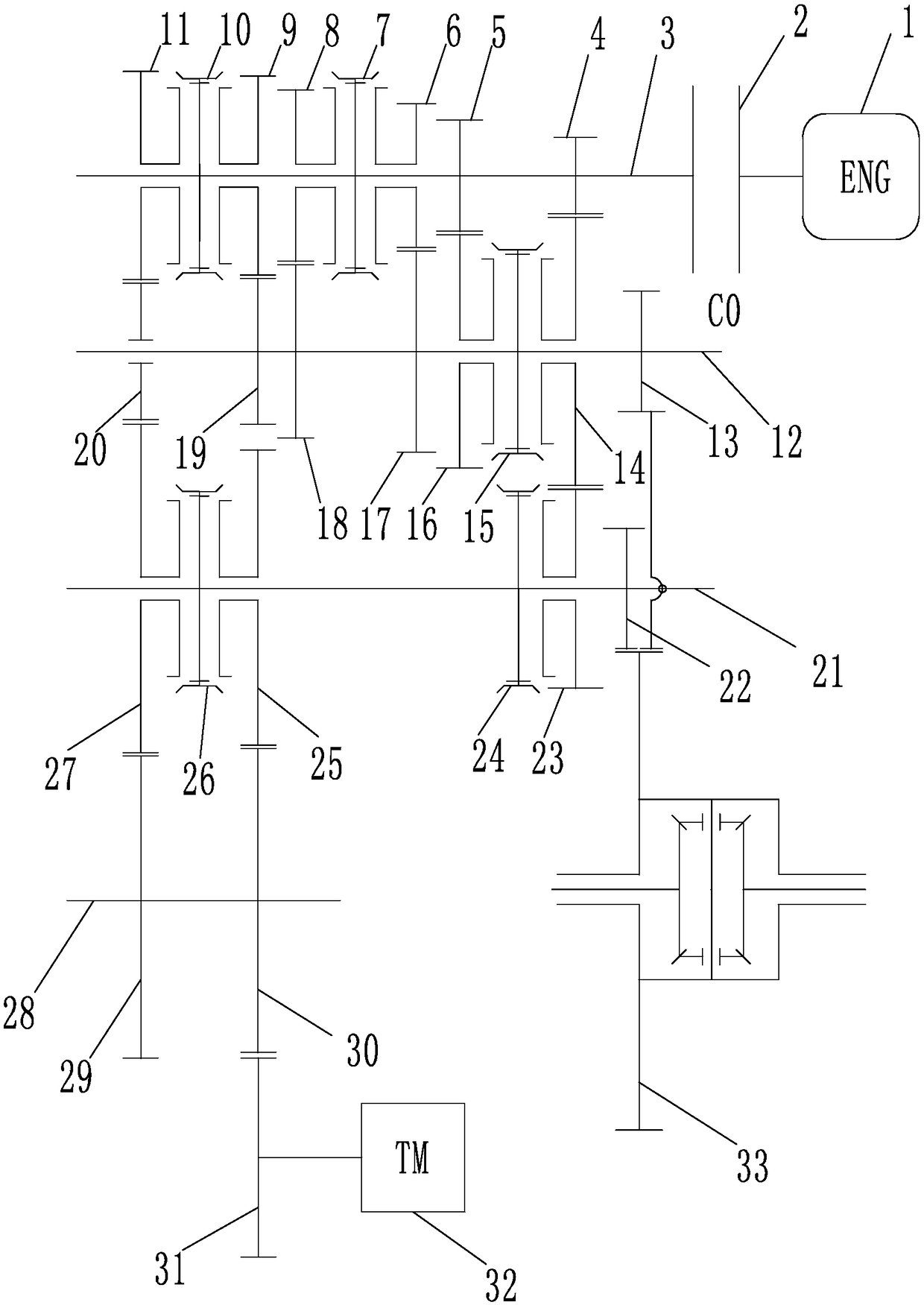

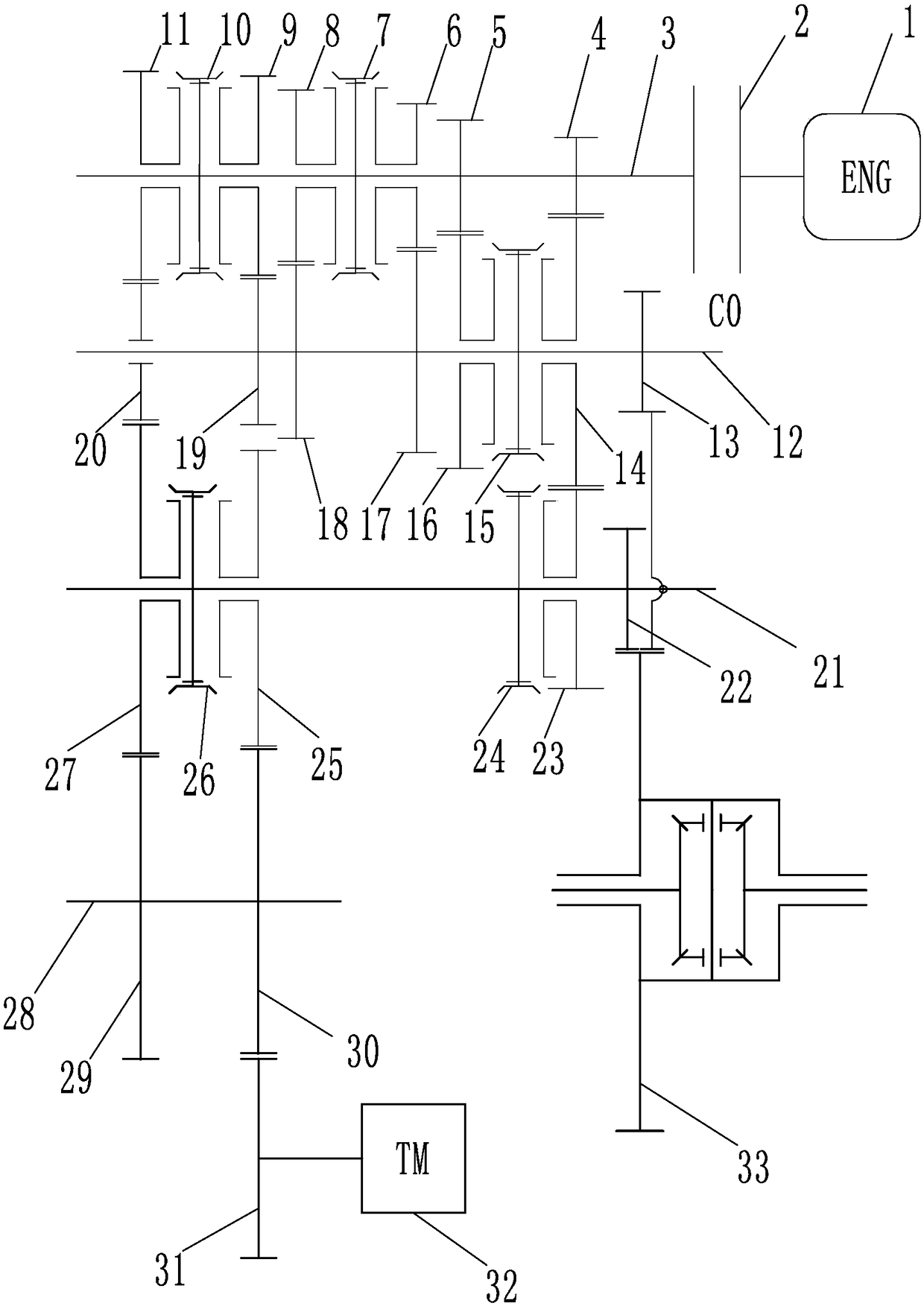

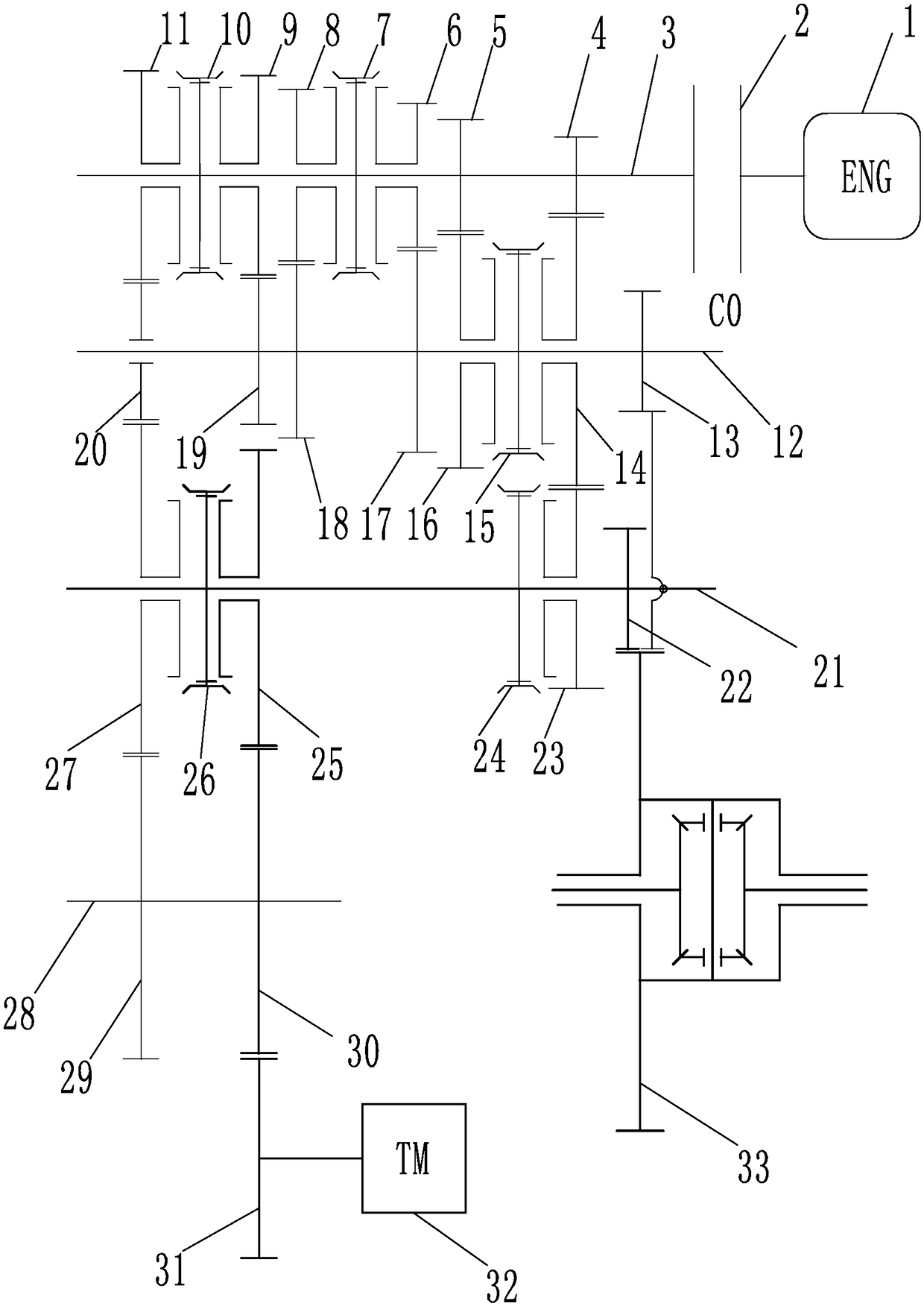

[0027] Such as figure 1 As shown, a transmission structure of a hybrid vehicle includes an engine 1, an intermediate shaft 12, a reverse gear shaft 21 and a motor intermediate shaft 28, wherein there is a clutch 2 between the output end of the engine 1 and the input end of the input shaft 3, so that the clutch 2 2 is selectively combined with or disengaged from the input shaft 3. The input shaft 3 is successively equipped with input shaft first gear gear 4, input shaft second gear gear 5, input shaft third gear gear 6, third and fourth gear synchronizer 7, input shaft fourth gear gear 8, input shaft fifth gear gear 9, and Gear synchronizer 10 and input shaft idle power generation gear 11, wherein: input shaft first gear teeth 4 and input shaft second gear teeth 5 are fixed on input shaft 3, and input shaft third gear 6, input shaft fourth gear 8, input shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com