PCB placing rack

A technology for placing racks and supporting racks, which is applied to containers, rigid containers, containers, etc. to prevent mechanical damage. It can solve the problems of scrapped circuit boards and scratches on the board surface, and achieve the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

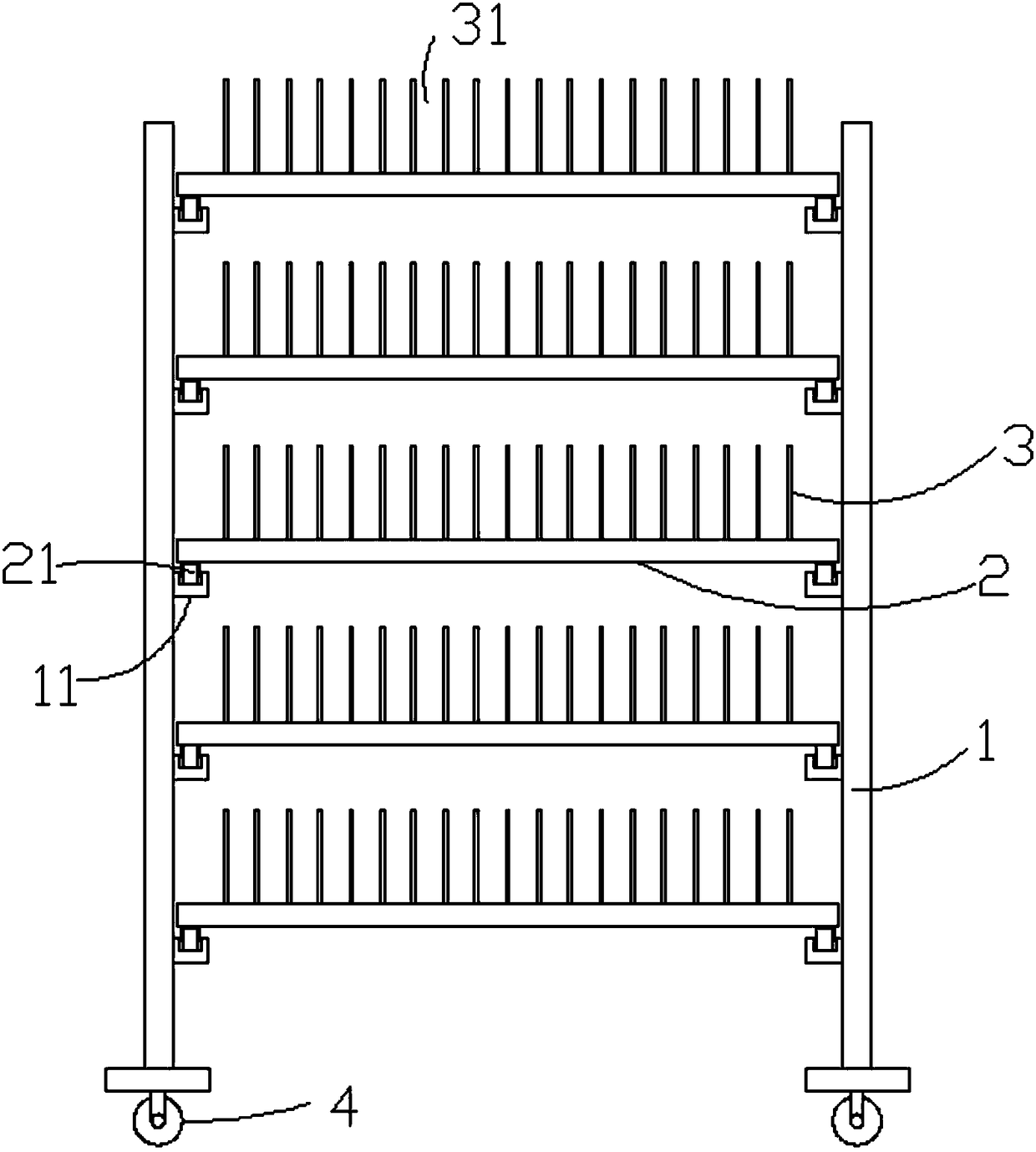

[0011] Such as figure 1 As shown, a PCB placement frame of the present invention includes a support frame 1, a supporting plate 2 and a partition 3, and a plurality of support blocks 11 are evenly layered on both inner side walls of the support frame 1, and on each support block 11 A chute is provided, and a pulley 21 is arranged on the lower end surface of the supporting plate 2, and the pulley 21 slides and is placed in the chute. A plurality of partitions 3 are arranged on the upper end surface of each supporting board 2 with a certain gap, and an accommodating groove 31 is formed between two adjacent partitions 3 .

[0012] For the convenience of moving the shelf, the bottom end of the support frame 1 is provided with universal wheels 4 .

[0013] When in use, a PCB board is placed in each accommodating groove 31 . The PCB boards are placed separately to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com