Easy-to-open food packaging component and method

A technology for food packaging and components, which is applied in the direction of closure devices, etc., can solve the problems of increasing extra cost, waste, convenience, low cost, and reliable opening problems and other problems, and achieves the effect of easy implementation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

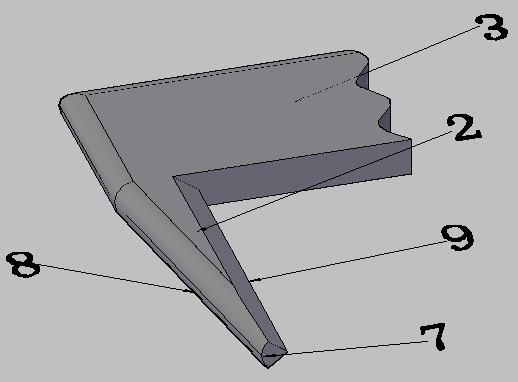

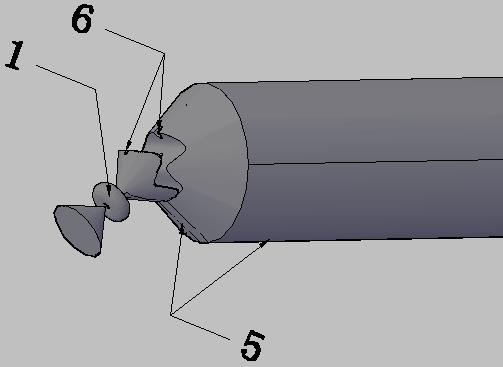

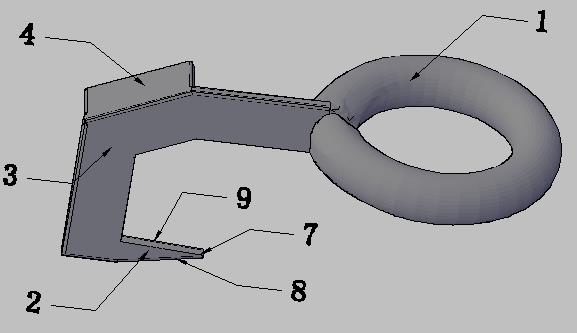

[0021] Only the sharp part is set on the nail, and the point of the sharp part can face the casing (the ability to face the casing means that the sharp part can pierce a hole in the casing after being manually twisted, not just the direction in the natural state), among which, for When other substances are packaged, it refers to the film or other packaging materials that can be tied towards the nails. It is preferred to face the bottom of the casing bundle, and use a sharp part to pierce a small hole from the bottom of the casing bundle, then pull the top of the casing and tear it along the casing seam. The sharp part can be prefabricated or stamped during the production of the nail.

Embodiment 2

[0023] Only the sharp part is set on the tie nail, and the sharp part is flexibly connected with the tie nail. The sharp part can adjust the direction to prevent accidental damage to casings and other packaging. Or connect with a flexible section, such as a small aluminum section connection that can bend.

Embodiment 3

[0025] The nail is provided with a sharp part and a protective part, wherein the protective part is a protective layer attached to the sharp part, which can be a rubber, plastic layer or cap coated or sheathed on it. When using, remove the protective layer or press hard to penetrate with the protective layer when piercing a hole. A pressing portion can be arranged on the nail to reduce the pressure on the hand when pressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com