Construction method for reinforcing turnout zone of criss-cross I-shaped steel and D beam combination system

A construction method, the technology of I-beam, applied in the direction of bridge reinforcement, roads, bridges, etc., can solve the problems of small application range, impossibility, and high construction risk, and achieve high safety and stability, low construction cost, and reduced demolition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

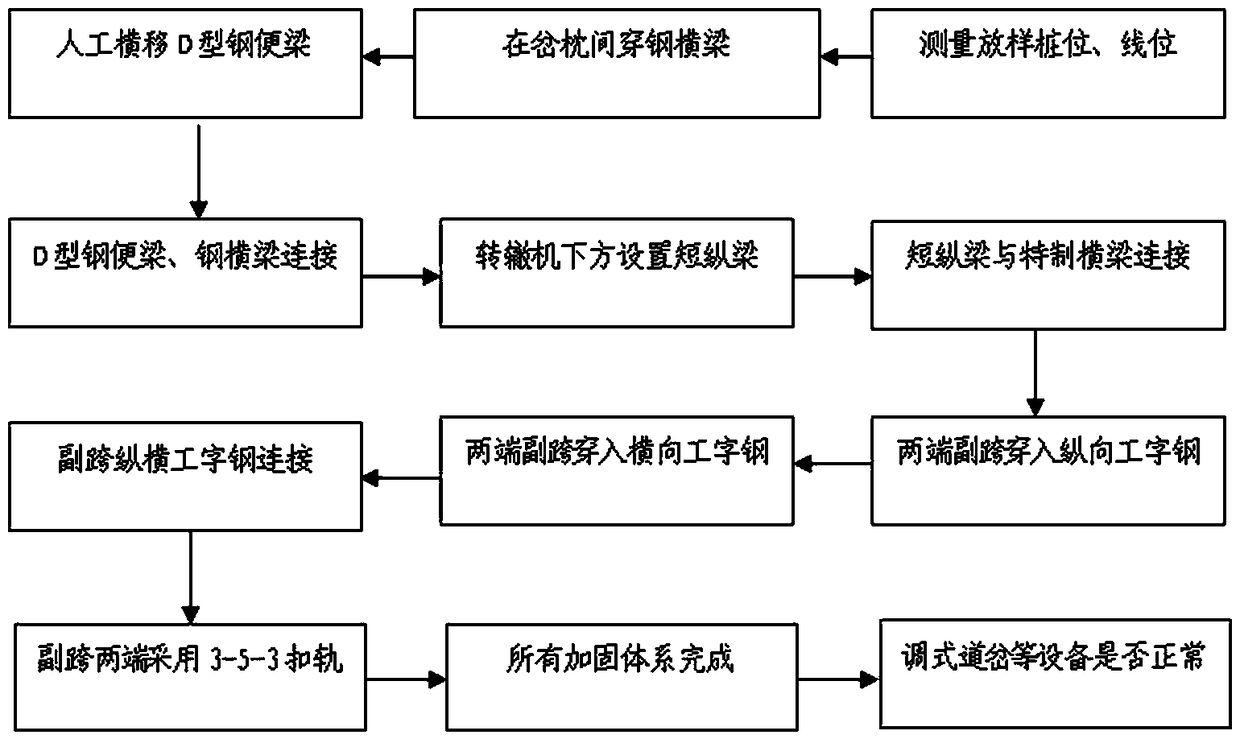

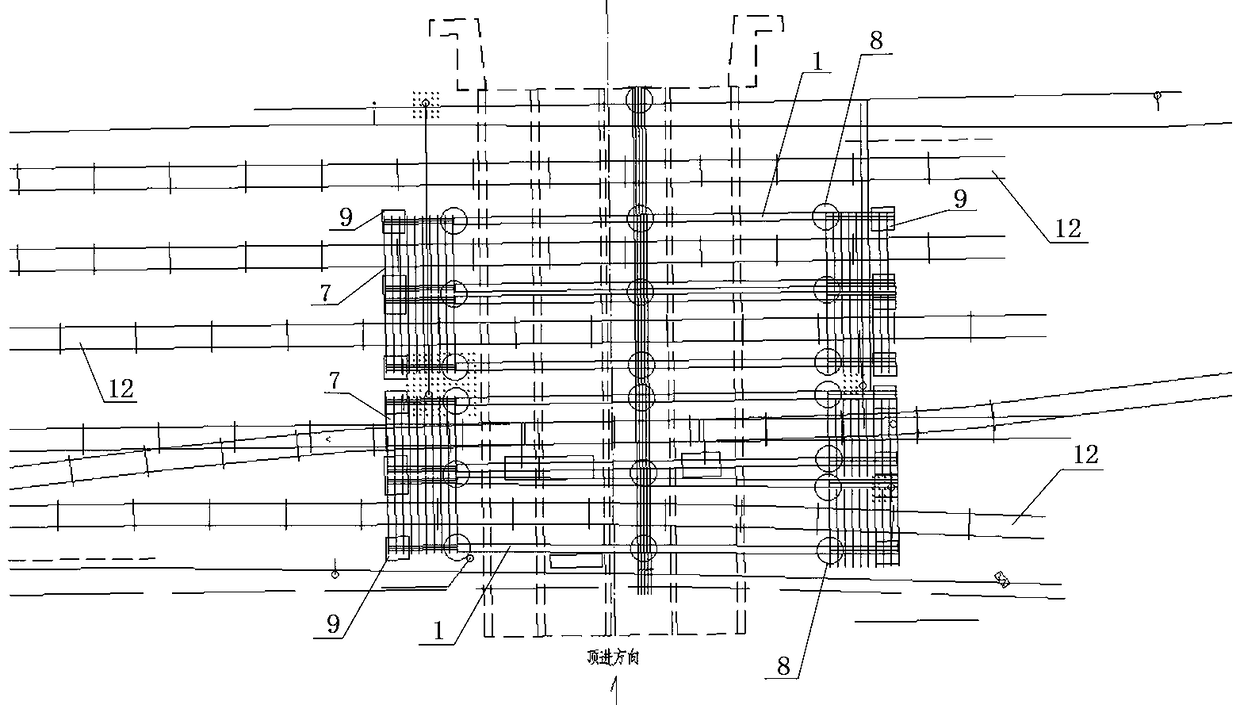

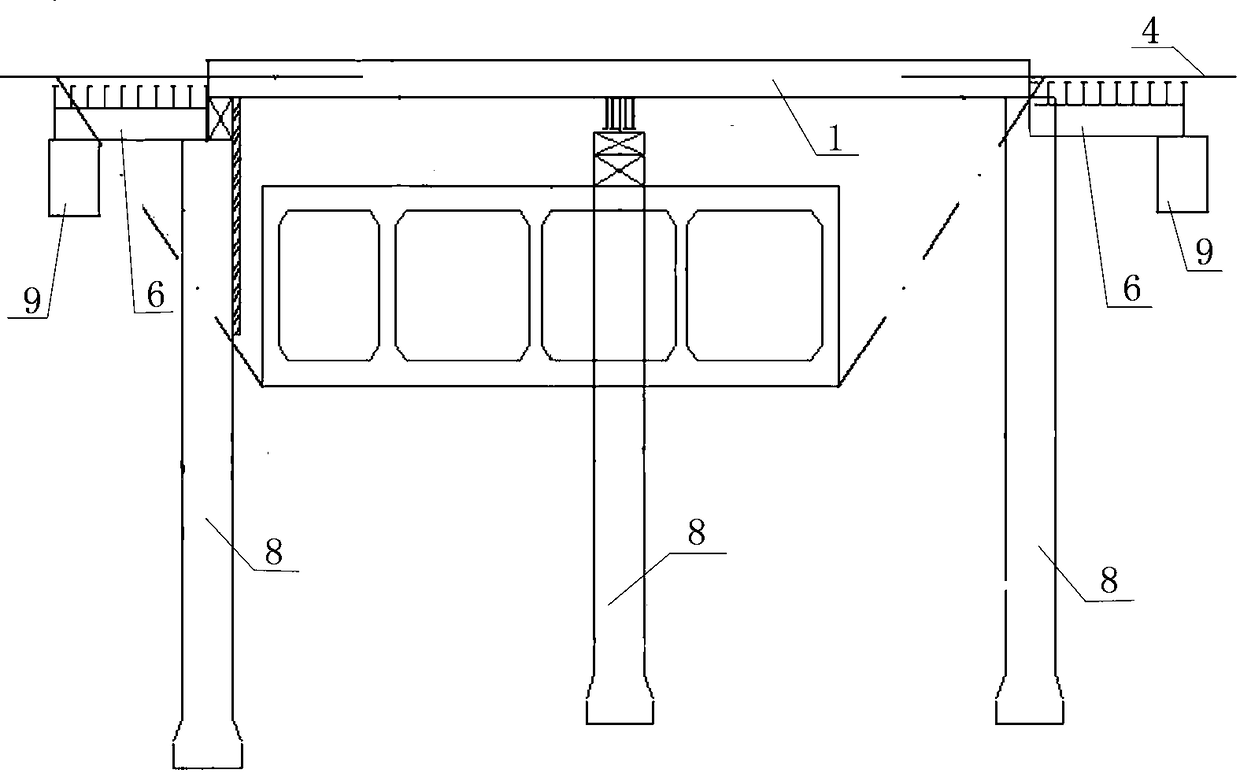

[0023] The technical solution claimed in the present invention will be specifically described in conjunction with the accompanying drawings.

[0024] 1. Artificial steel crossbeam and transverse D-shaped steel beam

[0025] Since there is no need for square concrete turnout sleepers in the turnout area, the spacing between sleepers cannot be squared and adjusted in advance, and the steel crossbeam 2 is penetrated in the middle of the turnout tie directly according to the coordinate position of the steel crossbeam. Manually move the D-shaped steel beam 1 horizontally, and set up a beam-moving platform on the outside of the existing road shoulder in advance. The beam-moving platform must be firm, and the height cannot exceed the elevation of the rail top; 2 roads are respectively set up at a distance of 3.5 meters from both ends of the D-shaped steel beam. The rail slideway uses the standard gauge large trolley on the railway to push the D-shaped steel beam 1 horizontally; when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com