Perforating-combined testing and sampling integrated device

A technology of joint operation and sampling tube, applied in the directions of measurement, production of fluid, wellbore/well components, etc., can solve the problems of complex core tool structure, small fluctuation of formation pressure, complex construction technology, etc., and achieve reliable well test interpretation results, The effect of large pressure fluctuation range and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

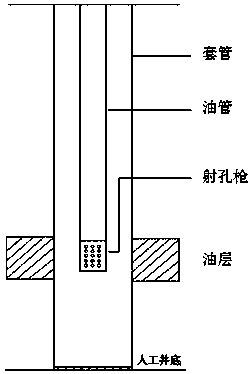

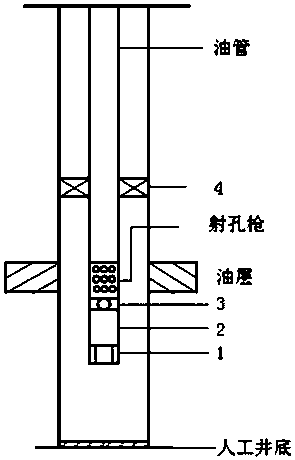

[0029] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

[0030] like figure 2 as shown, figure 2 It is a structural diagram of a device integrated with perforation testing and sampling of the present invention. The integrated device for testing and sampling combined with perforation is composed of a pressure thermometer support cylinder 1 , a vacuum sampling cylinder 2 , a pressure control switch 3 and a packer 4 .

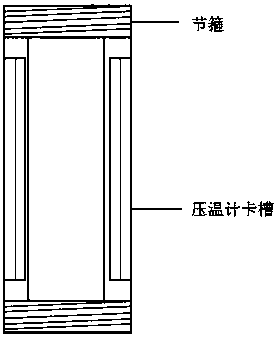

[0031] like image 3 As shown, the pressure thermometer support cylinder 1 is a hollow thick-walled metal cylinder, and the side wall is symmetrically opened with a pressure thermometer slot. The pressure change in the liquid stage and the pressure recovery in the later stage. It is connected to the vacuum sampling cylinder through the joint hoop. In one embodiment, the upper joint is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com