Variable load rotating shaft testing machine

A technology of rotating shaft and testing machine, which is applied in the testing of mechanical parts, testing of machine/structural parts, measuring devices, etc. It can solve the problems of bulky size, unreasonable design of rotating shaft size, loss of work efficiency and miniaturization indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

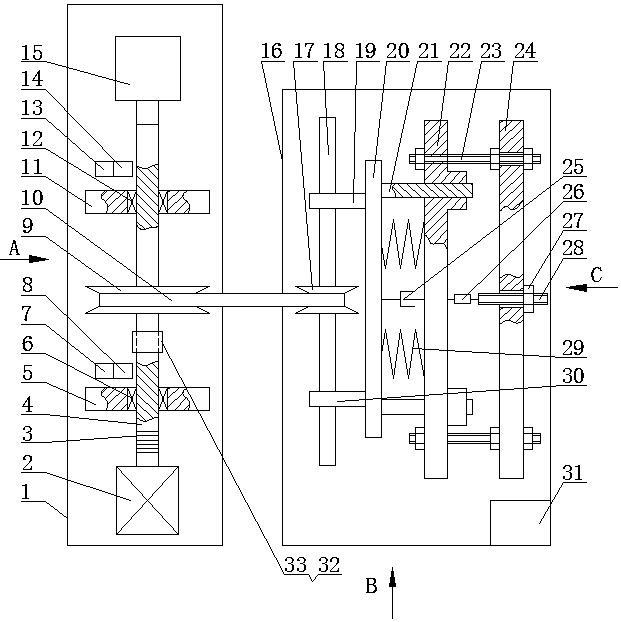

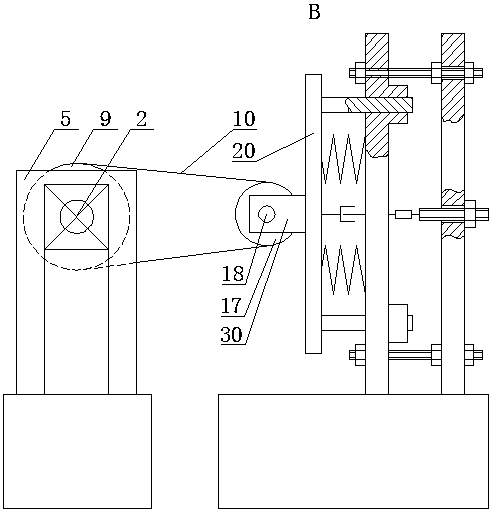

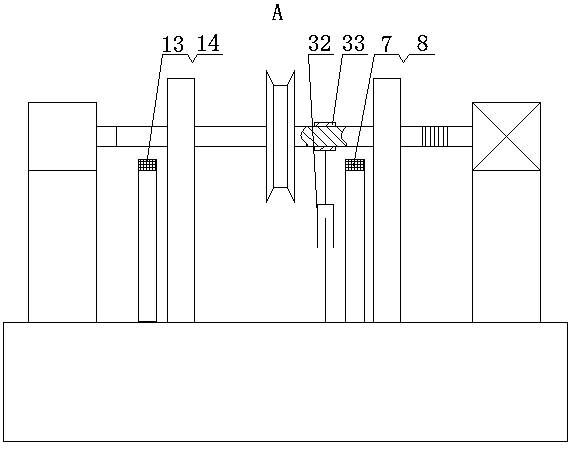

[0014] The rotating shaft in general mechanical equipment mainly bears two kinds of loads, one is the torque load around the shaft center, and the other is the lateral external force acting on the shaft. These two kinds of loads act alone or simultaneously, and the size of the load It often changes, and the present invention tests the load-bearing working state of the rotating shaft 4 by applying a torque load and a lateral force load to the bearing wheel 9 on the rotating shaft 4, thereby performing a performance test on the rotating shaft 4, and matching the rotating shaft 4 Test the performance of the bearings to verify whether the performance indicators of the rotating shaft 4 and the bearings meet the requirements of the working conditions.

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: as figure 1 As shown, on the test bench 1 on the left side, two parallel upper support plates 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com