Method and equipment for extracting weak fault signal features of rolling bearings

A technology for rolling bearings and fault signals, which is applied in the field of feature extraction of weak fault signals of rolling bearings, can solve the problems of large discrete interval, influence fault feature extraction, roughness, etc., and achieves improved accuracy and speed, good time-frequency resolution and transient detection. Ability, the effect of reducing distraction and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

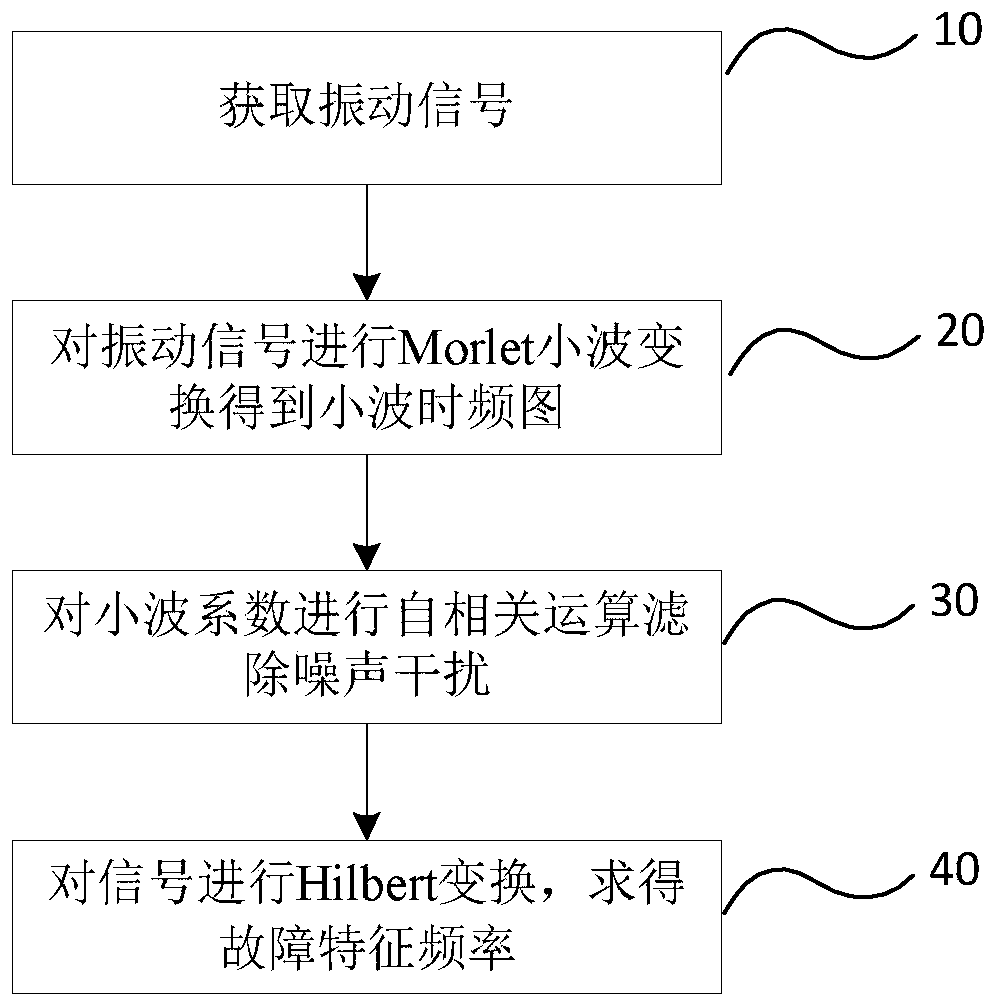

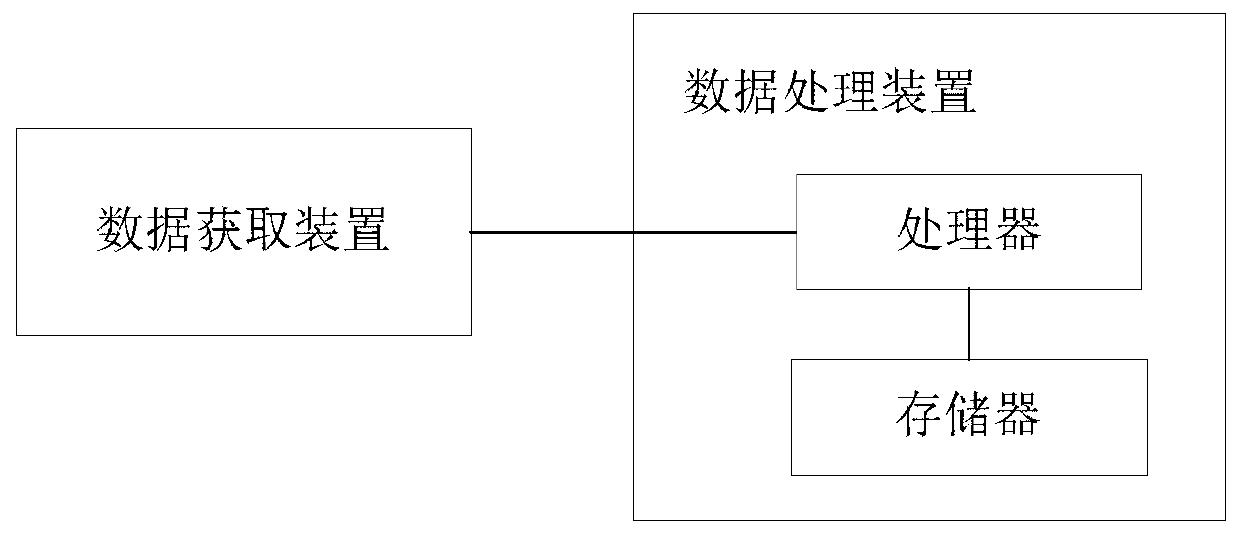

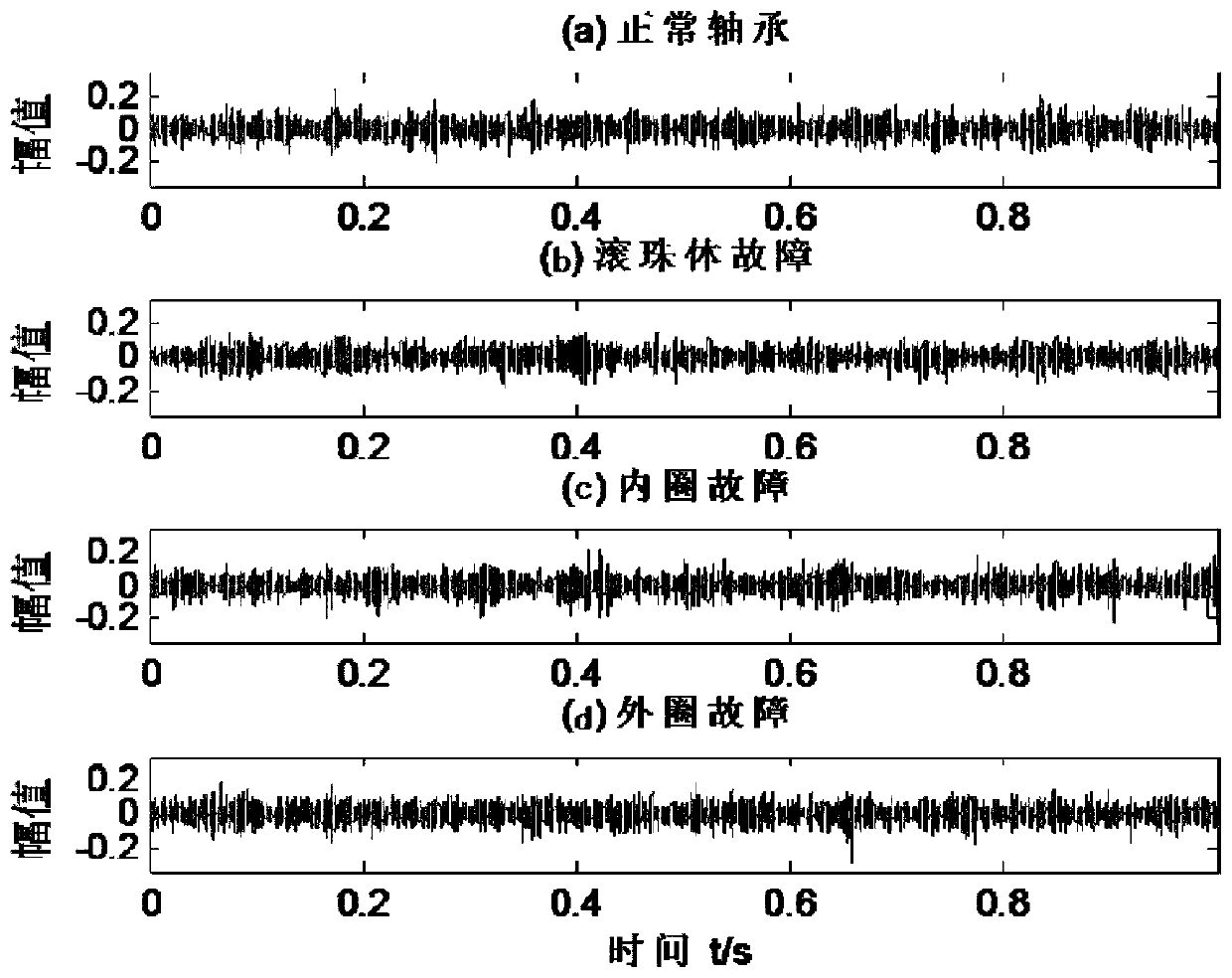

[0060] refer to figure 1 and figure 2 , the present invention provides a method for feature extraction of rolling bearing weak fault signals based on an improved wavelet time-frequency diagram, the method comprising the following steps: step 10, obtaining the vibration signal of the rolling bearing; step 20, performing continuous wavelet decomposition on the vibration signal to obtain Continuous wavelet time-frequency diagram; step 30, perform autocorrelation operation on the wavelet coefficients, and filter out noise interference; step 40, extract the envelope characteristics of the autocorrelation function obtained through the autocorrelation operation of the wavelet coefficients and perform envelope spectrum analysis to obtain the fault characteristic frequency. Different steps are performed by corresponding devices in the extraction dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com