A cavity filter and debugging method

A cavity filter and debugging method technology, which is applied to waveguide-type devices, circuits, electrical components, etc., can solve problems such as high requirements for debugging personnel, large debugging workload, and difficulty in fine-tuning, achieving good debugging effects and saving manpower. Cost, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

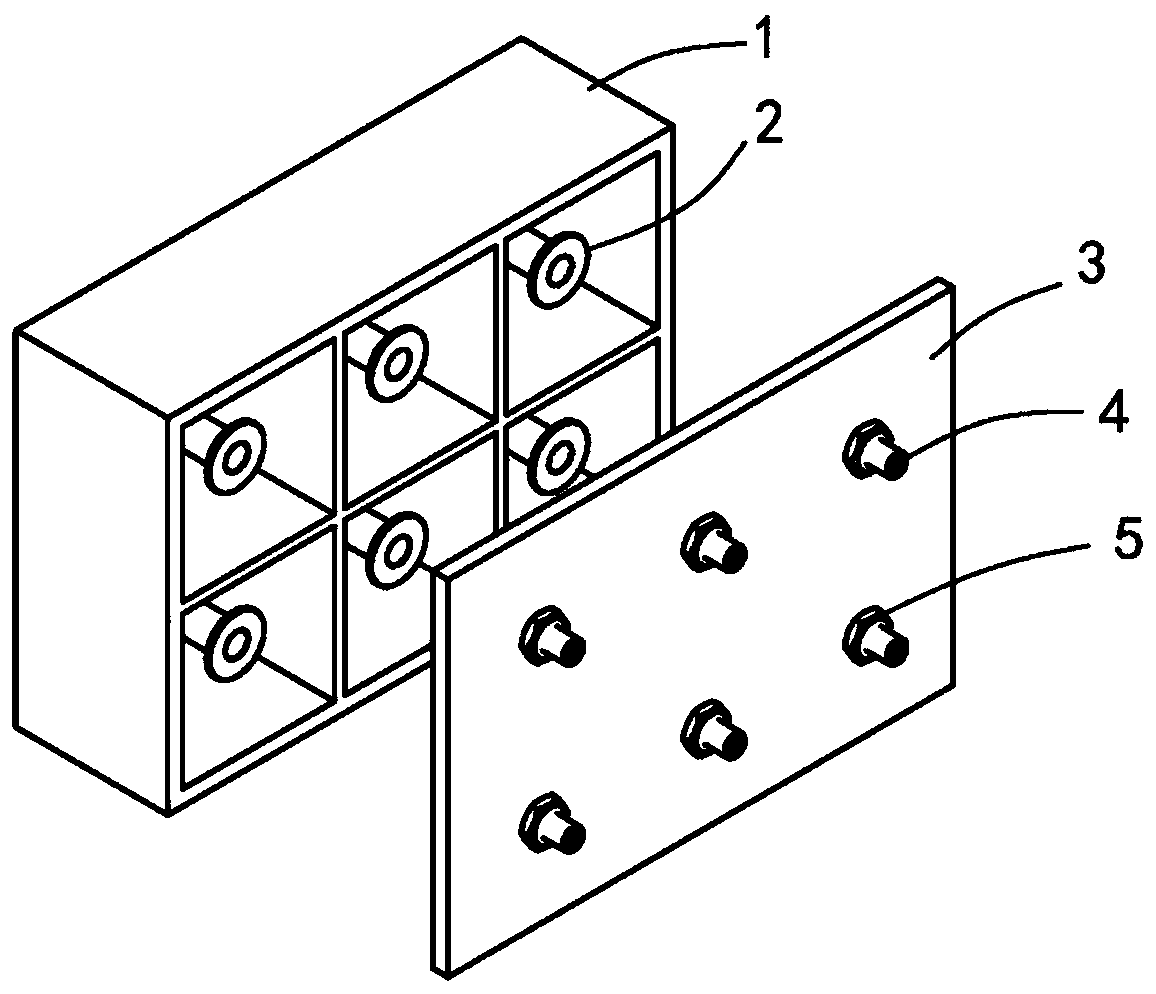

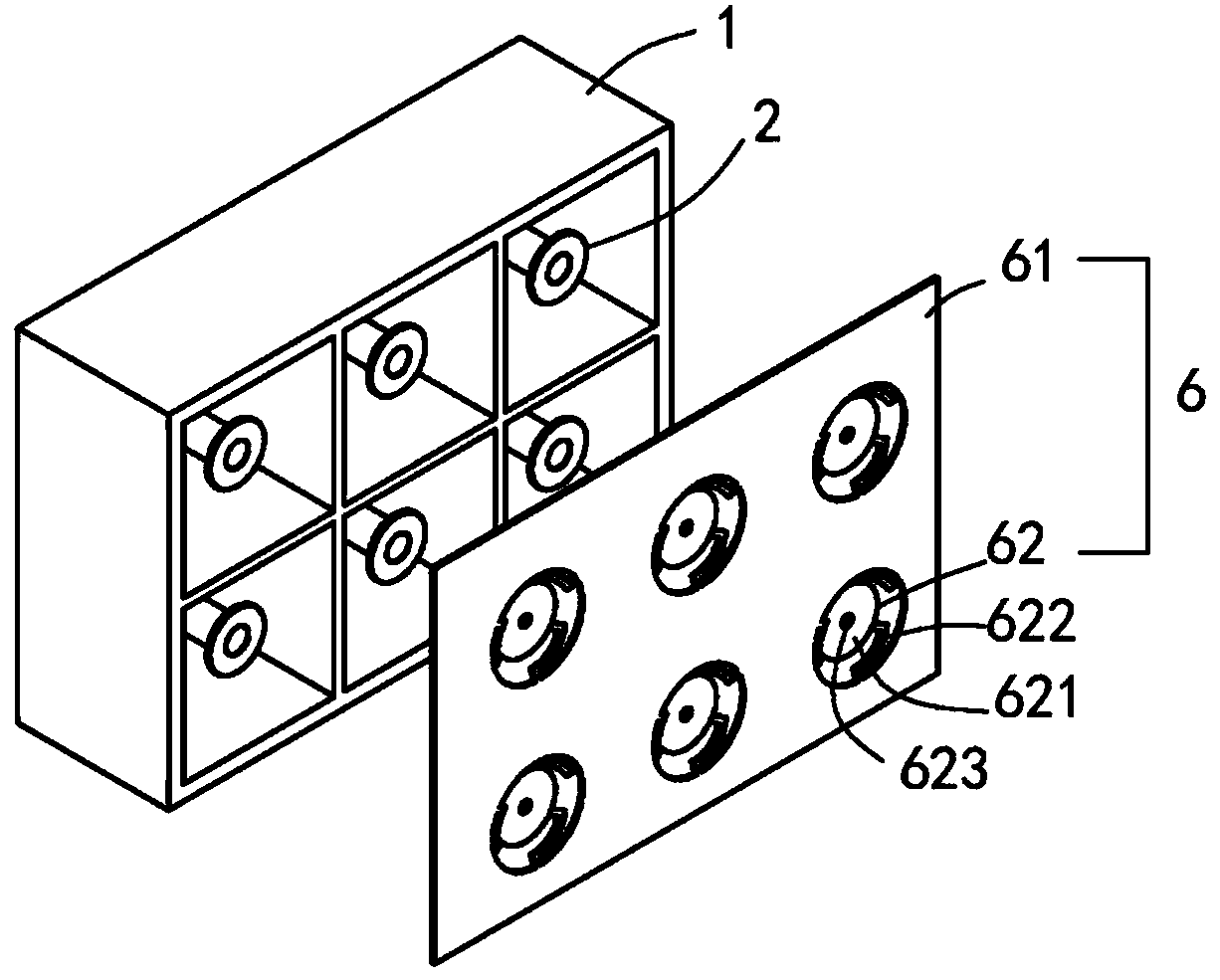

[0039] Embodiment one of the present invention, such as figure 2 , image 3 shown. The cavity filter includes a cavity 1 , several resonant rods 2 , and a debugging mechanism 6 . The upper end of the cavity 1 is open, the resonant rod 2 is installed on the inner bottom of the cavity 1, and the debugging mechanism 6 covers the upper surface of the cavity 1 and is fixed on the cavity 1 by screws.

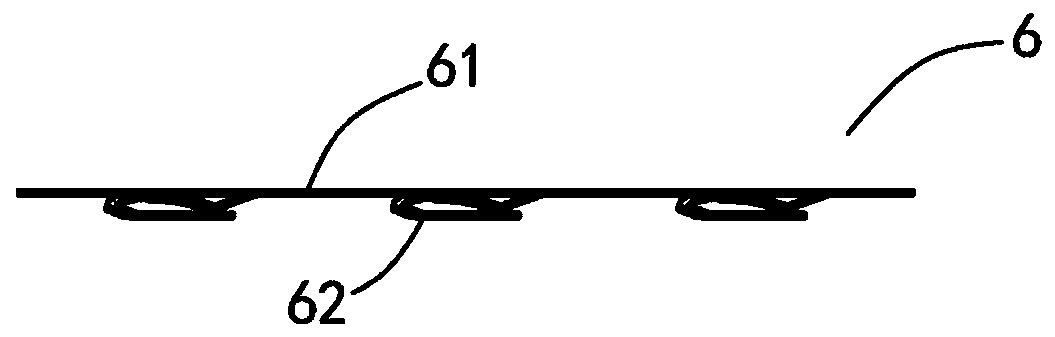

[0040]The debugging mechanism 6 includes a debugging cover 61 and several tuning elements 62 , each tuning element 62 corresponds to each resonating rod 2 one by one, and the tuning elements 62 and the debugging cover 61 are integrally formed. The tuning element 62 is a circular sheet 621 structure, three strip-shaped connecting parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com