Parallel drive piezoelectric stick-slip linear motor and drive method therefor

A linear motor and drive technology, applied in the field of micro-nano precision drive and positioning, can solve the problems of small output thrust, low precision, and short stroke, and achieve the effect of large output thrust, high precision, and reduced frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

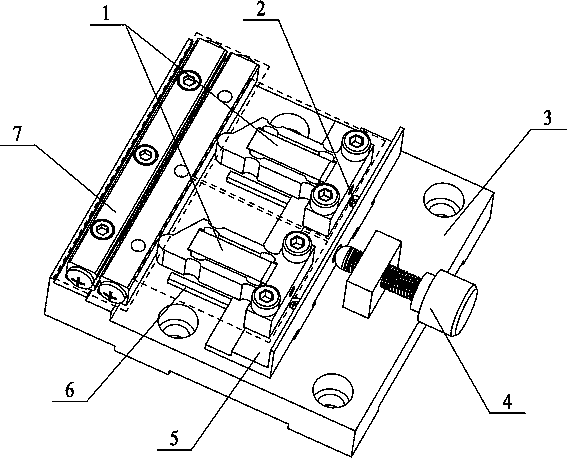

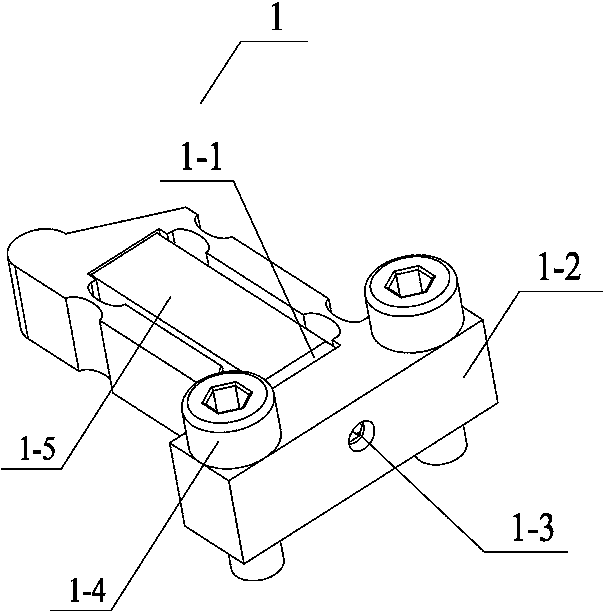

[0032] Specific implementation mode one: combine Figure 1~Figure 10 To illustrate this embodiment, this embodiment provides a specific implementation of a parallel-driven piezoelectric stick-slip linear motor. The specific implementation of the parallel-driven piezoelectric stick-slip linear motor is expressed as follows:

[0033] The parallel driven piezoelectric stick-slip linear motor consists of an inclined trapezoidal drive assembly 1, a locking screw 2, a base 3, a dovetail platform displacement regulator 4, a dovetail platform 5, a dovetail platform limit bar 6 and a sliding assembly 7 composition. Among them, two oblique trapezoidal drive components 1 are fixed on the dovetail platform 5 in parallel, the locking screw 2 is installed in the corresponding threaded hole of the dovetail platform 5, the dovetail platform displacement regulator 4 is installed on the rear end of the base 3, and the dovetail platform 5 is installed On the base 3 and defined in the dovetail p...

specific Embodiment approach 2

[0040] Specific implementation mode two: combination Figure 11~12 To illustrate this embodiment, this embodiment proposes a specific implementation of a driving method for a parallel-driven piezoelectric stick-slip linear motor. The driving method for a parallel-driven piezoelectric stick-slip linear motor is expressed as follows:

[0041] The driving method of the parallel drive piezoelectric stick-slip linear motor can be divided into output enhancement type and motion emergency stop type. The uneven distribution of the axial stiffness of the trapezoidal drive assembly 1 produces lateral displacement, adjust the normal contact pressure between the inclined trapezoidal drive assembly 1 and the sliding assembly 7, and then adjust the friction between the inclined trapezoidal drive assembly 1 and the sliding assembly 7 ; At the same time, under the excitation of different combinations of asymmetrical electrical signals, various driving modes such as output enhancement type and...

specific Embodiment approach 3

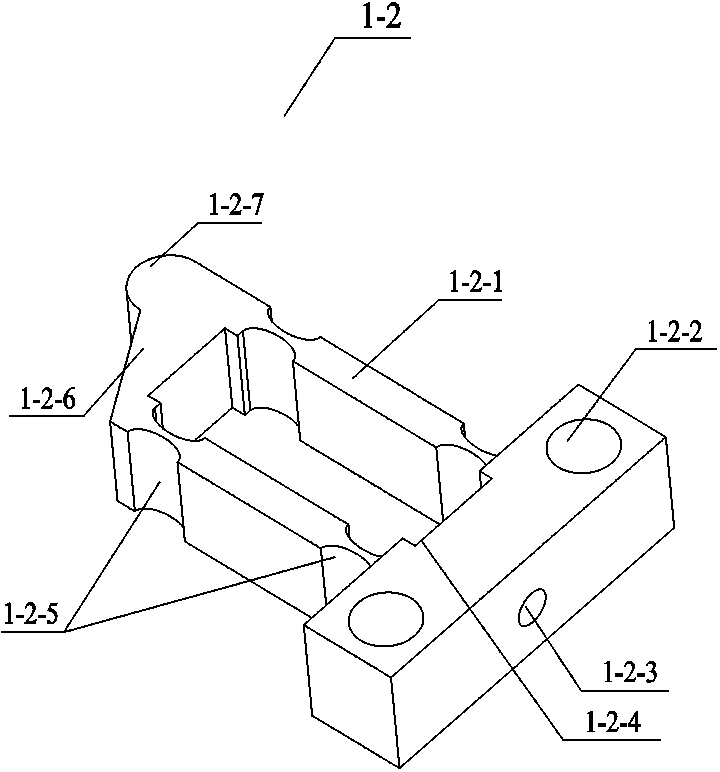

[0065] Specific implementation mode three: combination Figure 11 , 13 , 14 This embodiment is described. This embodiment proposes a specific implementation of a parallel-driven piezoelectric stick-slip linear motor driving method in which the inclined trapezoidal drive assembly 1 is installed back to back. The driving method of the driven piezoelectric stick-slip linear motor is expressed as follows:

[0066] The driving method of the parallel-driven piezoelectric stick-slip linear motor with inclined trapezoidal drive components installed back to back can be divided into output enhancement type and motion emergency stop type, mainly the parallel driven piezoelectric stick-slip linear motor with the inclined trapezoidal drive components installed The linear motor adopts the inclined trapezoidal beam 1-2-6 structure, so that the axial stiffness of the inclined trapezoidal drive assembly 1 is unevenly distributed to cause lateral displacement, and the positive pressure of cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com