Mobile monitoring equipment convenient for disassembling

A monitoring equipment, mobile technology, applied to camera bodies, color TV parts, TV system parts, etc., can solve problems such as unclear images, blurred lens surfaces, and inability to accurately reflect on-site conditions. Expand the monitoring range, ensure clarity, and avoid the effect of climbing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

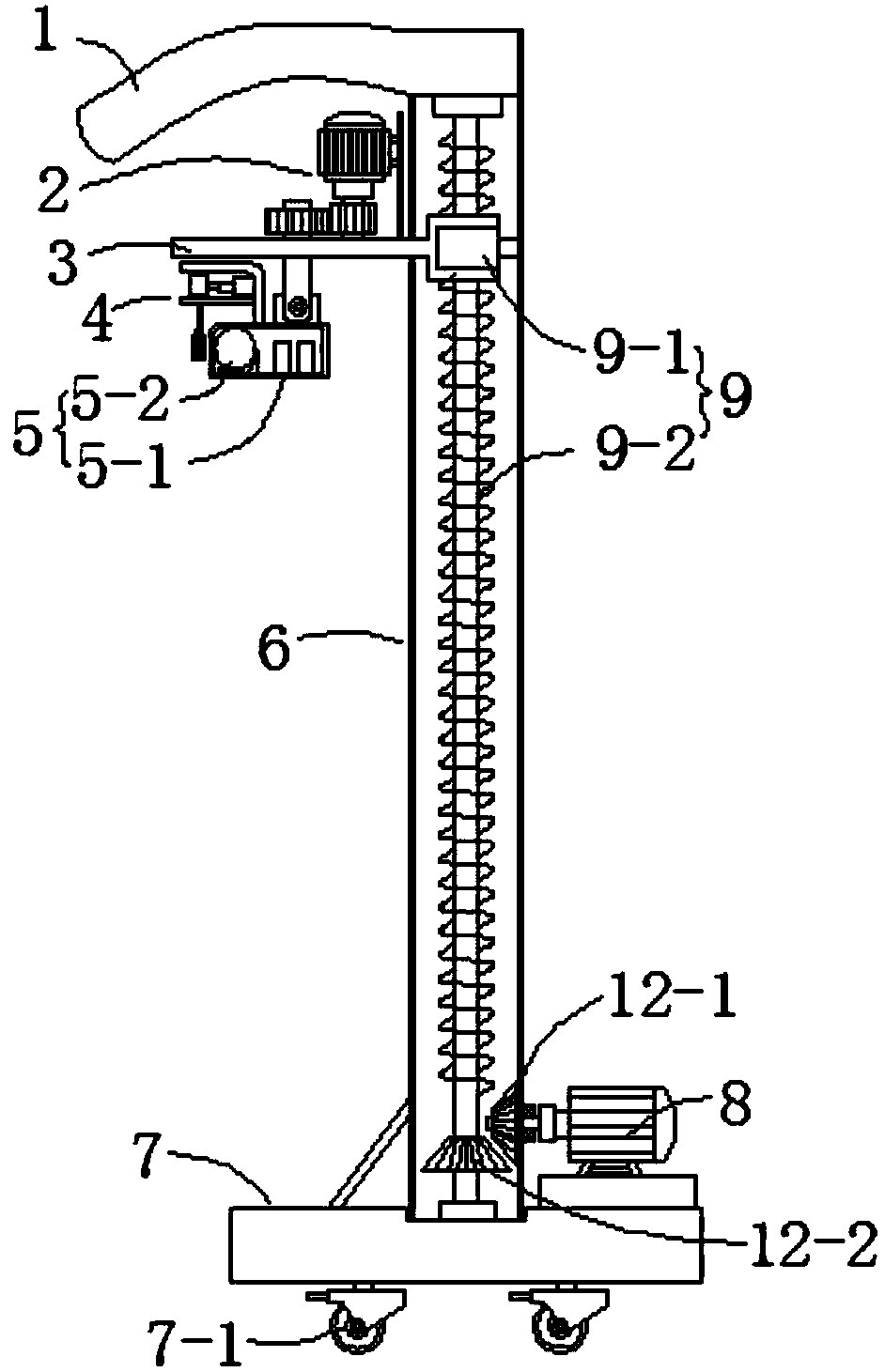

[0023] Such as figure 1 As shown, this embodiment provides a mobile monitoring device that is easy to disassemble, including a mobile base 7 with a mobile wheel set 7-1 at the bottom and a mounting case 6 vertically arranged on the mobile base 7. The mounting case 6 The top is provided with an arc-shaped protective plate 1, the installation housing 6 is provided with a lifting mechanism 9, and the mobile base 7 is provided with a lifting motor 8 that drives the lifting mechanism 9 up and down. The mounting plate 3 is provided with a rotary drive mechanism 2 on the mounting plate 3, and the rotary drive mechanism 2 is connected with a monitoring component 5. The monitoring component 5 includes a transparent casing 5-1 connected with the rotary drive mechanism 2 and is arranged on the transparent casing 5-1. Inside and away from the monitoring camera 5-2 on the side of the installation housing 6, the transparent housing 5-1 is connected with a retractable cleaning mechanism 4 fo...

Embodiment 2

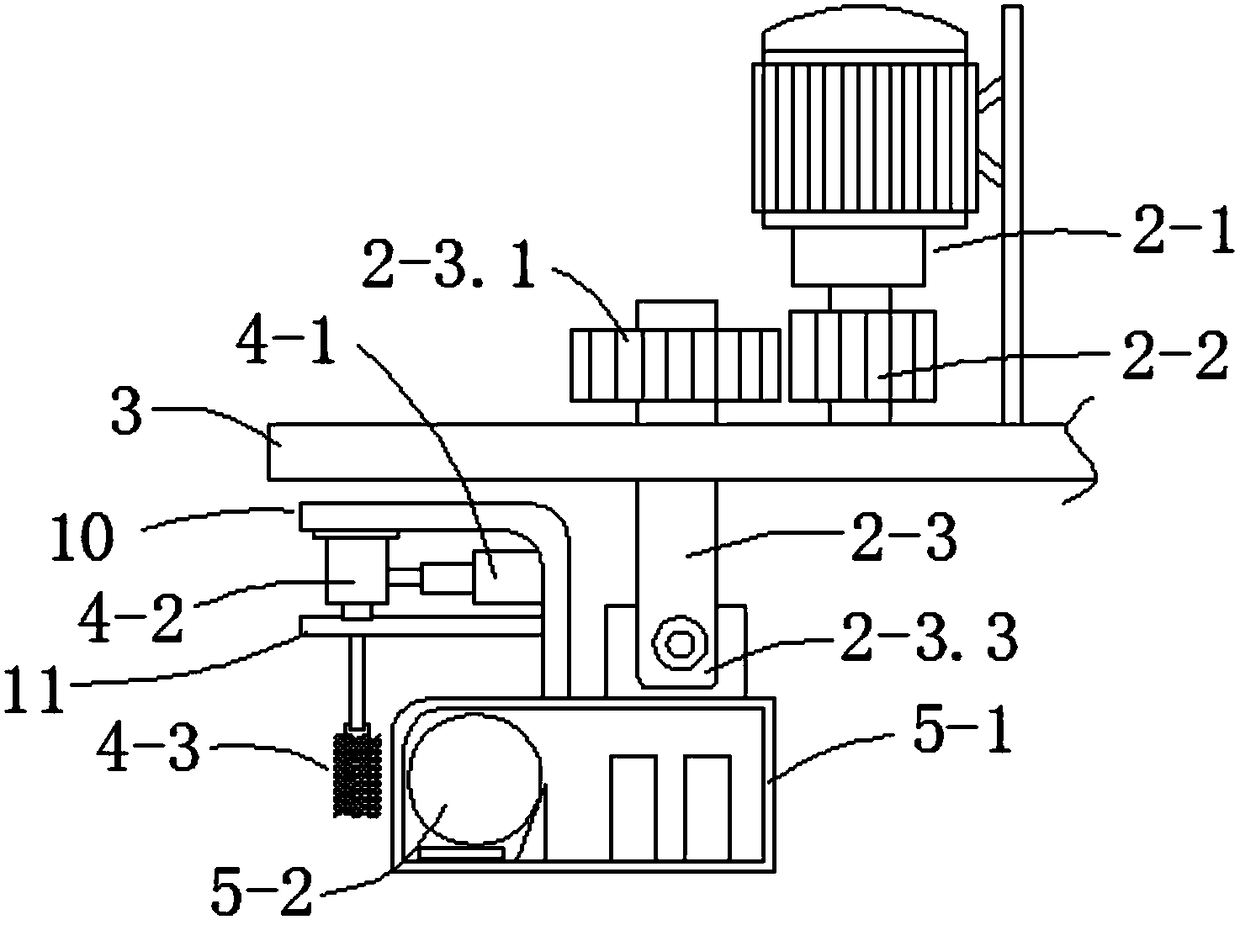

[0028] Such as figure 2 As shown, the present embodiment is further optimized on the basis of embodiment 1, specifically:

[0029] The top of the transparent housing 5-1 is provided with an L-shaped mounting plate 10 comprising a vertical portion and a horizontal portion, the vertical portion is fixedly connected to the transparent housing 5-1, and the retractable cleaning mechanism 4 includes a The three-stage sleeve assembly 4-1, the inverted scrubbing cylinder 4-2 connected to the output end of the three-stage sleeve assembly 4-1, and the brush head 4- with bristles evenly distributed on the outside connected to the piston rod of the scrubbing cylinder 4-2 3. The bottom of the scrubbing cylinder 4-2 is connected with a sliding mounting seat, and the bottom of the horizontal part is provided with a slide rail matched with the sliding mounting seat.

[0030] The vertical portion is connected with a limiting plate 11 parallel to the horizontal portion, and the limiting plate...

Embodiment 3

[0033] This embodiment is further optimized on the basis of Embodiment 2, specifically:

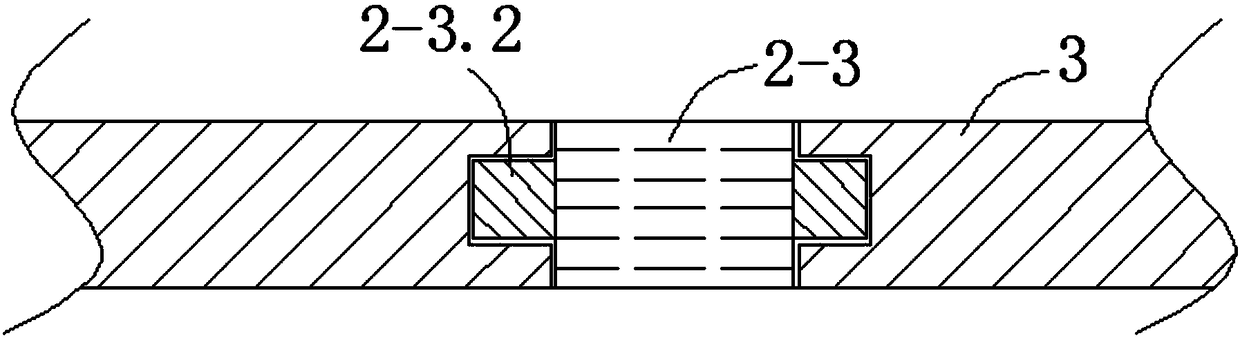

[0034] The rotary drive mechanism 2 includes a rotary motor 2-1 arranged on the mounting plate 3, a driving gear 2-2 sleeved on the output shaft of the rotary motor 2-1, and a driven gear meshed with the driving gear 2-2. The connecting shaft 2-3 of the meshing teeth 2-3.1, the connecting shaft 2-3 passes through the mounting plate 3 and is connected with the transparent casing 5-1, and the connecting shaft 2-3 is fixedly connected with a limit on the outer wall of the circumference of the inner section of the mounting plate 3. The position collar 2-3.2, the inside of the mounting plate 3 is dug with a ring groove that matches the limit collar 2-3.2, and the end of the connecting shaft 2-3 is symmetrically provided with two connecting lugs 2-3.3, and the two connecting lugs 2 -3.3 are respectively fixedly connected with the transparent casing 5-1 by screws.

[0035]In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com