Preparation device of dope-dyed fibers with gradient colors

A technology of dope coloring and fiber, which is applied to the processing of textile materials, equipment configuration, textiles and papermaking, and textile materials processing. It can solve the problems affecting the work efficiency of personnel, and achieve the effect of eliminating climbing operations, convenient use, and reducing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

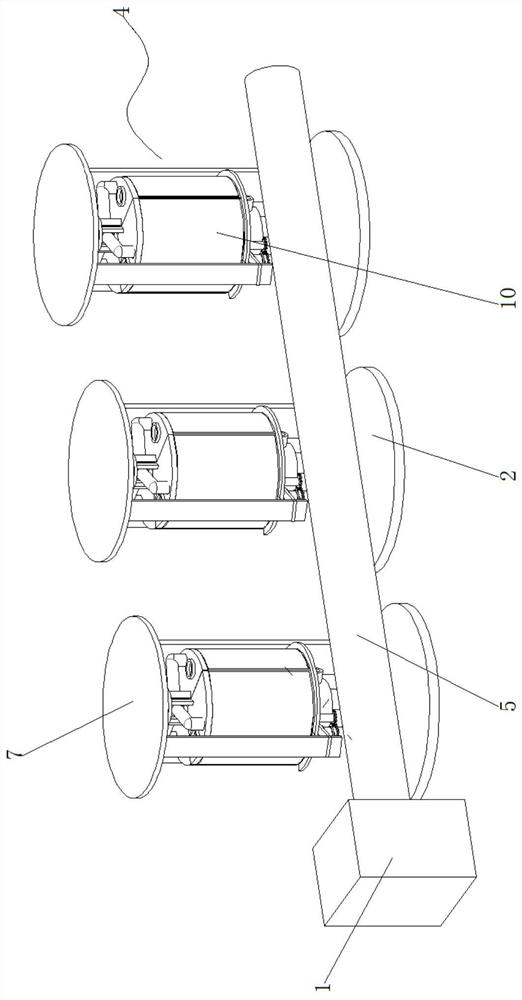

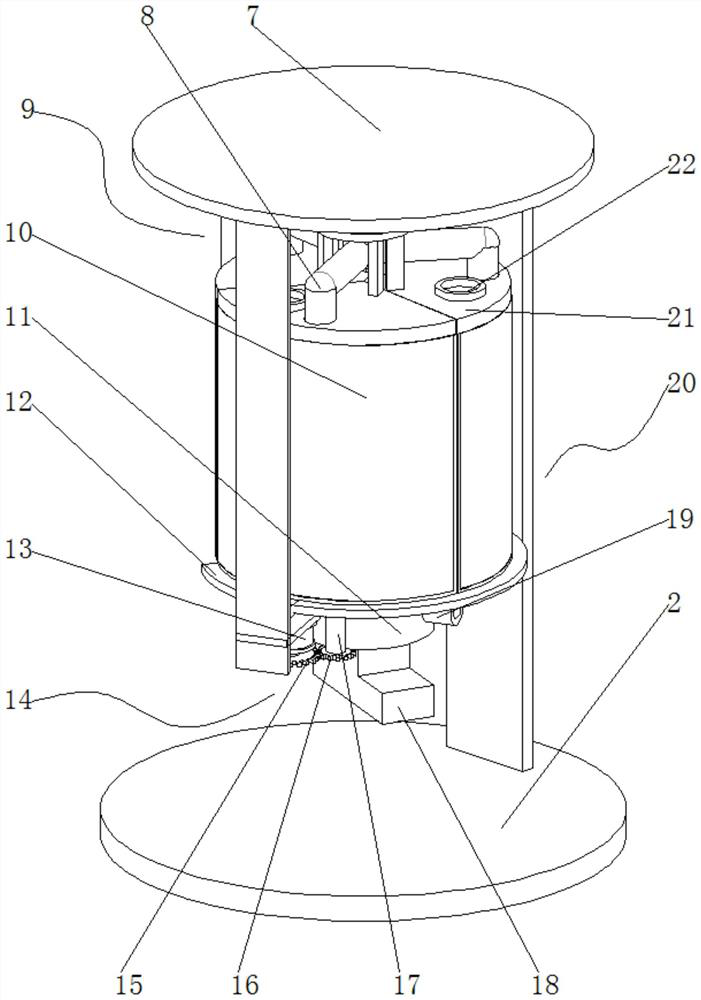

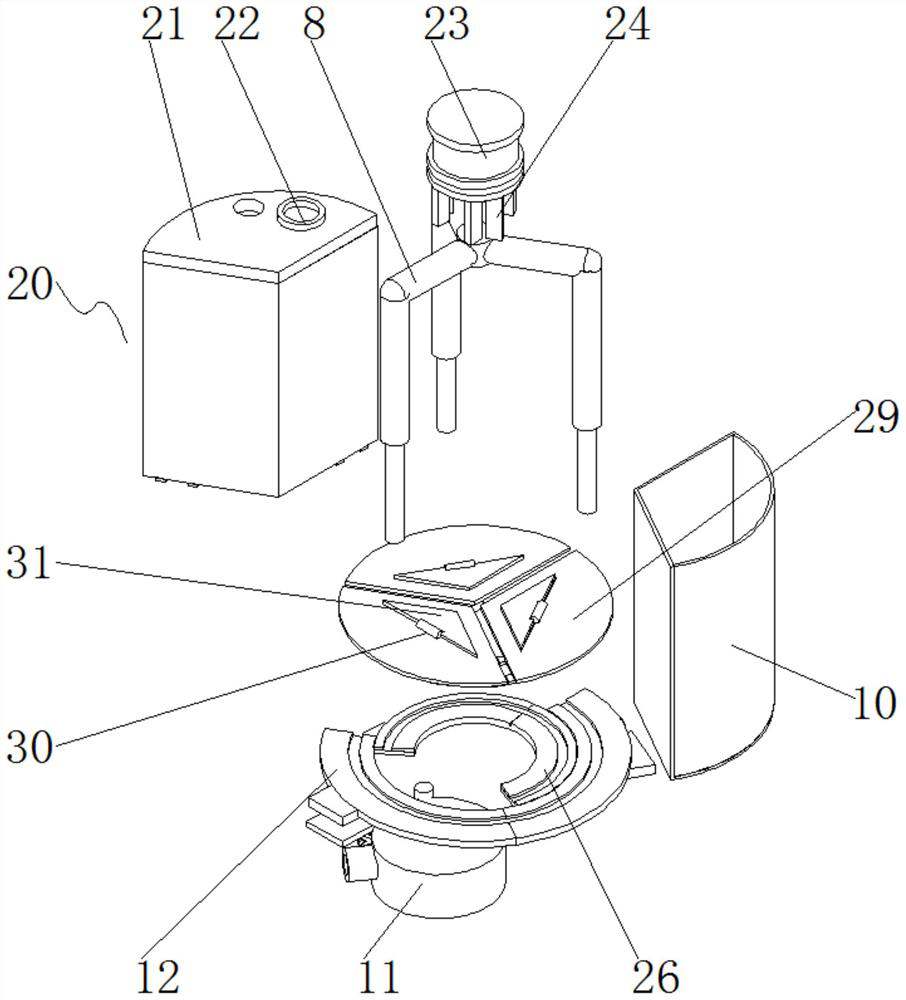

[0026] The embodiment of the present invention provides a kind of gradient color dope dyed fiber preparation device, such as Figure 1-7 As shown, a fan 1, a spinning machine 5 and a plurality of color matching extruding mechanisms 4 are included. A plurality of color matching extruding mechanisms 4 are connected to the spinning machine 5, and the fan 1 is connected to the port of the spinning machine 5. The color matching extruding mechanism 4 includes a support frame 2, a top plate 7, a rotating mechanism 9, a resin mixer 11, three The material storage assembly 20 , the gap ring disk 12 , the rotating assembly 14 and the extrusion head 18 . The lower half of support frame 2 is pre-buried in the ground, and the gap of gap ring plate 12 is adapted to the bottom surface of material storage assembly 20, gap ring plate 12 is arranged on support frame 2, and top plate 7 is arranged on the top of support frame 2. The three storage assemblies 20 are in contact with each other and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com