Three-dimensional method of shirt front collar

A collar and shirt technology, applied in the three-dimensional field of collars, can solve the problems of collapsed collars, lack of three-dimensional sense, and unsmooth collar lines, and achieves the effect of round collar lines and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Such as Figure 4-7 As shown, this three-dimensional method of shirt front collar includes:

[0027] In the first step, boilerplate improvements include:

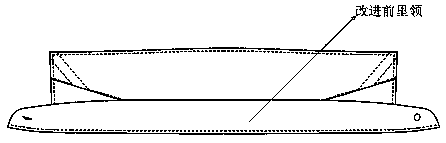

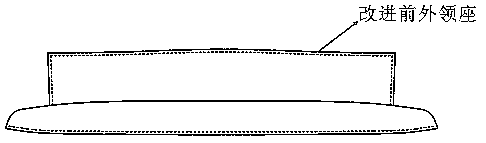

[0028] 1. The samples of outer collar seat 1 and inner collar 2 are changed from the original basic straight line model to an arc shape that is more in line with the trend of the human shoulder and neck from the front collar to the neck and shoulders. The outer collar seat 1 and inner collar 2 of the shirt are based on the collar seat After the change, the template is adjusted synchronously;

[0029] 2. The inner collar 2 sample is 0.8cm according to the outer collar seat 1 or so;

[0030] 3. Increase the inner collar 2, collar pocket 4 and middle collar knife eye 3;

[0031] The second step, sewing process improvement includes:

[0032] 1. When putting on the outer collar seat 1, use an ordinary sewing machine to first fix the collar mouths at both ends according to the collar eyelets 4, and then fix the collar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com