Bearing cleaning device convenient to assemble and disassemble

A bearing cleaning and equipment technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as unfavorable production efficiency, high labor intensity, easy to leave, etc., to achieve convenient unloading, improve Production efficiency, effective cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

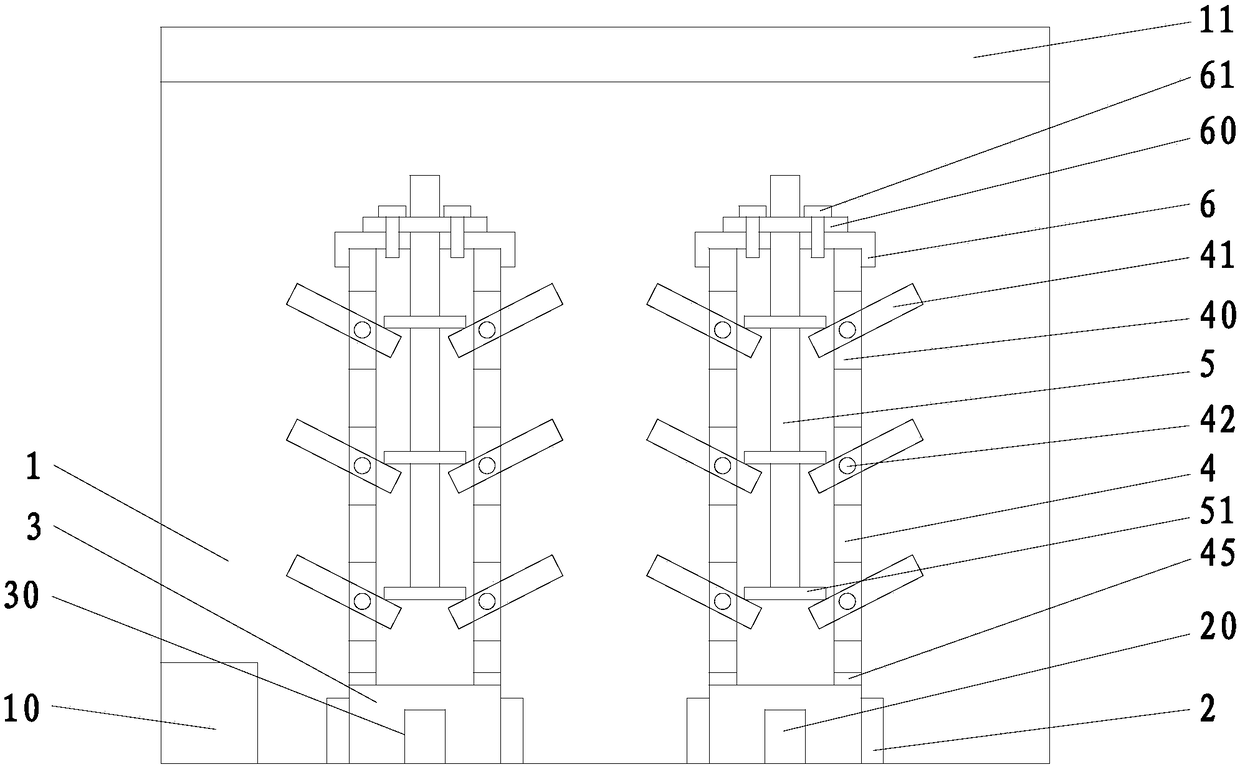

[0014] refer to figure 1 , the present invention is a kind of bearing cleaning equipment that is easy to load and disassemble, including a cleaning box 1, an ultrasonic generator 10, a fixing ring 2, a fixing column 3, a mounting cylinder 4, a rotating rod 41, a pressure plate 51, a stretching column 5, and a locking mechanism , the cleaning box 1 is provided with an ultrasonic generator 10, the top of the cleaning box 1 is covered with a box cover 11, a number of fixing rings 2 are fixed on the bottom wall of the cleaning box 1, and the fixing columns 3 are inserted in the fixing ring 2 , the top of the fixed column 3 is fixed with an installation cylinder 4, and the installation cylinder 4 is provided with several layers of installation areas from top to bottom, and each installation area is composed of a number of installation grooves 40 that run through the side walls of the installation cylinder 4 at the same level. Composition, the installation groove 40 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com